ISO 13832:2013

(Main)Aerospace — Wire, aluminium alloy and copper-clad aluminium conductors — General performance requirements

Aerospace — Wire, aluminium alloy and copper-clad aluminium conductors — General performance requirements

ISO 13832:2013 specifies the dimensions, electrical characteristics and mechanical characteristics of aluminium-based and copper-clad aluminium (CCA) conductors, for lightweight aircraft electrical cables and aerospace applications. It applies to stranded conductors over the nominal cross-sectional area range 0,22 mm2 to 107 mm2 inclusive. It is not applicable to conductors for conventional copper-based cables, fire-resistant cables or for thermocouple extension cables. Conductors for copper-based cables are specified in ISO 2635, for fire-resistant cables are specified in ISO 1967 and for thermocouple extension cables are specified in ISO 8056 1.

Aéronautique et espace — Conducteurs en alliage d'aluminium chemisé cuivre pour câbles électriques — Exigences générales de performance

General Information

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 13832

First edition

2013-03-15

Aerospace — Wire, aluminium alloy and

copper-clad aluminium conductors —

General performance requirements

Aéronautique et espace — Conducteurs en alliage d’aluminium chemisé

cuivre pour câbles électriques — Exigences générales de performance

Reference number

©

ISO 2013

© ISO 2013

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2013 – All rights reserved

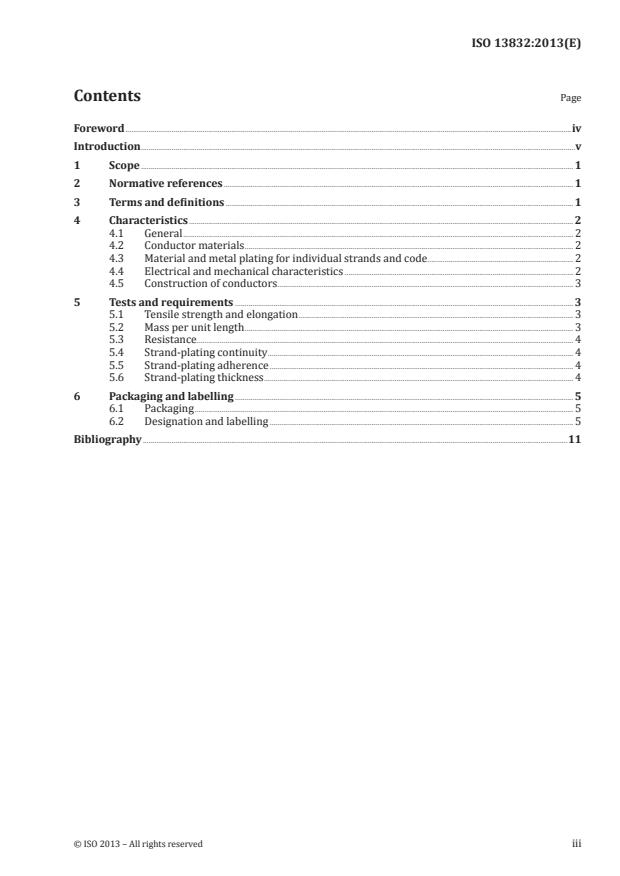

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Characteristics . 2

4.1 General . 2

4.2 Conductor materials . 2

4.3 Material and metal plating for individual strands and code . 2

4.4 Electrical and mechanical characteristics . 2

4.5 Construction of conductors . 3

5 Tests and requirements . 3

5.1 Tensile strength and elongation . 3

5.2 Mass per unit length . 3

5.3 Resistance . 4

5.4 Strand-plating continuity . 4

5.5 Strand-plating adherence . 4

5.6 Strand-plating thickness . 4

6 Packaging and labelling . 5

6.1 Packaging . 5

6.2 Designation and labelling . 5

Bibliography .11

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2. www.iso.org/directives

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received. www.iso.org/patents

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

The committee responsible for this document is ISO/TC 20, Aircraft and space vehicles, Subcommittee

SC 1, Aerospace electrical requirements.

iv © ISO 2013 – All rights reserved

Introduction

This International Standard is the general performance requirements of the wires with aluminium and

copper-clad aluminium conductors for aerospace.

The need for International Standardization in the Aerospace industry cannot be overemphasized.

Multinational projects abound in the construction industry and all major airlines use equipment produced

in different continents. The mixture of specifications and standards combine to increase the chances

of maintenance errors, no more so than in the interconnection system. Power plant manufacturers

in France may use conductors and terminations manufactured in Europe mating at the firewall with

terminations and conductors manufactured in North America. This can result in different contacts,

crimp tools and settings, and insulating stripping tools being required to work on mating connectors.

The same would apply to many types of equipment.

The requirement for close or “clipped” tolerance, lightweight conductors can provide the opportunity

to address many of these problems by overcoming the long-standing issue of AWG versus metric sizes.

This International Standard introduces a list of aluminium-based lightweight conductors for aerospace

cables. This list supplements the existing list of standard metric conductors which has not received

worldwide acceptance. The list is derived from EN 3719, prEN 4651 and MIL-W-7072(MS25191).

The constructions presented are those which are considered to be standards within the emerging

rules governing aircraft cables, e.g. seven strands minimum, copper-clad aluminium for size 22 and

smaller. However, it does take advantage of the lightest weight for each size. The resultant standard is

therefore a mixture of conductors with metric and imperial origins which gives the greatest advantage

to constructors and users for the future.

This International Standard:

— obeys existing rules regarding conductors for aircraft;

— gives the lightest weight for each size/rating currently used;

— standardizes the conductor cross-sectional area throughout the world aerospace industry;

— enables the standardization of terminations and the crimp tools used to produce the joints;

— reduces the number of insulation stripping tools required to service aircraft;

— enables the world industry to concentrate its efforts on improving interconnection technology

knowing that a world market exists;

— enables regulatory authorities (CAA, FAA, JAA, etc.) to make rules regarding the interconnection

system which applies internationally.

All these will, by reducing complexity, reduce servicing errors and contribute to aircraft safety.

INTERNATIONAL STANDARD ISO 13832:2013(E)

Aerospace — Wire, aluminium alloy and copper-

clad aluminium conductors — General performance

requirements

1 Scope

This International Standard specifies the dimensions, electrical characteristics and mechanical

characteristics of aluminium-based and copper-clad aluminium (CCA) conductors, for lightweight

aircraft electrical cables and aerospace applications. It applies to stranded conductors over the nominal

2 2

cross-sectional area range 0,22 mm to 107 mm inclusive.

It is not applicable to conductors for conventional copper-based cables, fire-resistant cables or for

thermocouple extension cables. Conductors for copper-based cables are specified in ISO 2635, for fire-

resistant cables are specified in ISO 1967 and for thermocouple extension cables are specified in ISO 8056-1.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ASTM B 566, Standard Specification for Copper-Clad Aluminum Wire

ISO 8815, Aircraft — Electrical cables and cable harnesses — Vocabulary

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 8815 and the following apply.

3.1

conductor code

numeric or alphanumeric code which designates conductor size and properties

[SOURCE: ISO 2635:2003, 3.1]

3.2

worldwide wire gauge

WWG

identification system, similar to the American wire gauge (AWG) system from which it has been derived,

for an international designation of wire cable sizes

[SOURCE: ISO 2635:2003, 3.2]

3.3

copper-clad aluminium

CCA

wire per ASTM B 566 class 15A which consists of an aluminium core with a continuous cladding of

copper thoroughly bonded to the core throughout

Note 1 to entry: See Figure 2.

4 Characteristics

4.1 General

The dimensions, electrical resistance, mechanical properties and mass of the conductors shall conform

to the values given in Table 5 for CCA wires and Table 6 for aluminium or aluminium alloy wires. The

shapes of conductors stranded in concentric lay, bunch or rope lay are illustrated in Figure 1. The wires

shall consist of stranded CCA, aluminium or aluminium alloy strands shown in Figure 2.

4.2 Conductor materials

The conductors in accordance with this standard of nominal cross-sectional area 0,25 mm (code 002)

to 0,40 mm (code 004) shall be produced from a 1 + 6 strands construction. The central strand is a

copper alloy strand or equivalent in ISO 2635, surrounded by six CCA strands (see Figure 1).

The conductors shall consist of individual CCA strands (see ASTM B 566 class 15A), aluminium strands

or aluminium alloy strands with the following composition, for cross-sections of greater than 0,25 mm :

For aluminium: Annealed aluminium (EC grade 99,5 %). See Table 1.

For copper: ETP(Electrolytic touch pitch) copper purity 99,9 % min.

For aluminium alloy: See Table 2.

The conductors shall be manufactured from unused materials that have been exposed only to processes

essential to their manufacture and application.

4.3 Material and metal plating for individual strands and code

The individual strands may be:

— uncoated CCA (code A);

— CCA with tin plating (code B);

— CCA with silver plating (code C);

— CCA with nickel plating (code D);

— pure aluminium (code E);

— aluminium alloy with nickel plating (code F)

Plating thicknesses shall be at least 1,0 μm for code C and according to Table 3 for code D.

4.4 Electrical and mechanical characteristics

−8 −8

The maximum resistivity at 20 °C shall be 2,78 × 10 Ω·m for CCA and 3,0 × 10 Ω·m for aluminium or

aluminium alloy.

The elongation at rupture on the complete conductor taken from the finished wire shall be ≥ 6 %.

The tensile strength of the complete conductor taken from the finished wire shall be at least 138 MPa

2 2

(138 N/mm ) for CCA and 105 MPa (105 N/mm ) for aluminium or aluminium alloy.

The elastic limit (at 0,2 % wire elongation) of the complete conductor taken from the finished wire shall

be at least 90 MPa (90 N/mm ) for CCA.

2 © ISO 2013 – All rights reserved

4.5 Construction of conductors

4.5.1 Lay length

For CCA conductor up to 5 mm cross-section inclusive (code 050), concentric conductors are used. The

length of lay of the strands of a concentric conductor, checked over the outside laye

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.