ISO 20949:2018

(Main)Aircraft — Smart contactor — General requirements

Aircraft — Smart contactor — General requirements

This document specifies the definitions, titles of design and general requirements and test methods to determine the performance of smart contactors for use in aircraft electrical power systems. The smart contactor consists of a switching driving circuit and a power switch for protection, action on control signals, and providing status information.

Aéronefs — Contacteurs intelligents — Exigences générales

General Information

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 20949

First edition

2018-11

Aircraft — Smart contactor — General

requirements

Aéronefs — Contacteurs intelligents — Exigences générales

Reference number

©

ISO 2018

© ISO 2018

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2018 – All rights reserved

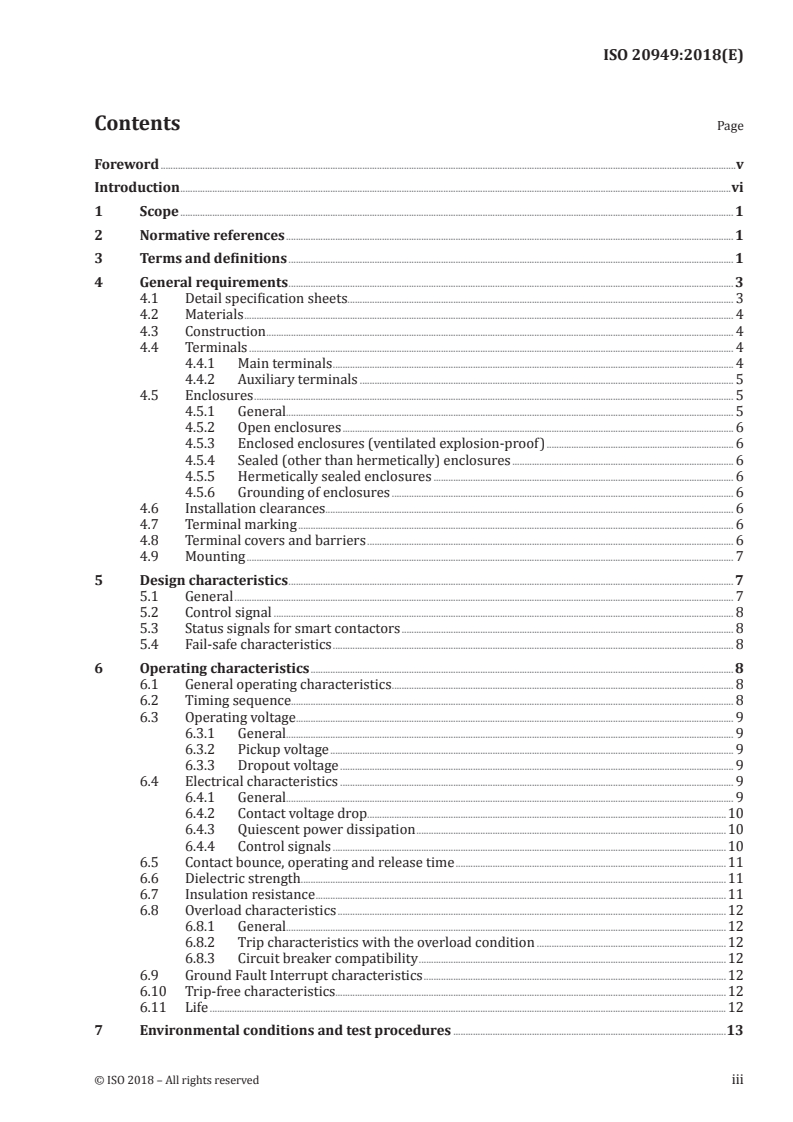

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 General requirements . 3

4.1 Detail specification sheets. 3

4.2 Materials . 4

4.3 Construction . 4

4.4 Terminals . 4

4.4.1 Main terminals . 4

4.4.2 Auxiliary terminals . 5

4.5 Enclosures . 5

4.5.1 General. 5

4.5.2 Open enclosures . 6

4.5.3 Enclosed enclosures (ventilated explosion-proof) . 6

4.5.4 Sealed (other than hermetically) enclosures . 6

4.5.5 Hermetically sealed enclosures . 6

4.5.6 Grounding of enclosures . 6

4.6 Installation clearances . 6

4.7 Terminal marking . 6

4.8 Terminal covers and barriers . 6

4.9 Mounting . 7

5 Design characteristics . 7

5.1 General . 7

5.2 Control signal . 8

5.3 Status signals for smart contactors . 8

5.4 Fail-safe characteristics . 8

6 Operating characteristics . 8

6.1 General operating characteristics . 8

6.2 Timing sequence. 8

6.3 Operating voltage . 9

6.3.1 General. 9

6.3.2 Pickup voltage . 9

6.3.3 Dropout voltage . 9

6.4 Electrical characteristics . 9

6.4.1 General. 9

6.4.2 Contact voltage drop.10

6.4.3 Quiescent power dissipation .10

6.4.4 Control signals .10

6.5 Contact bounce, operating and release time .11

6.6 Dielectric strength.11

6.7 Insulation resistance .11

6.8 Overload characteristics .12

6.8.1 General.12

6.8.2 Trip characteristics with the overload condition .12

6.8.3 Circuit breaker compatibility .12

6.9 Ground Fault Interrupt characteristics .12

6.10 Trip-free characteristics.12

6.11 Life .12

7 Environmental conditions and test procedures .13

8 Qualification Tests .13

8.1 General .13

8.2 Visual and mechanical examination .14

8.3 Timing sequence.15

8.3.1 Turn-off time .15

8.3.2 Turn-on time .15

8.4 Operating voltage .16

8.4.1 General.16

8.4.2 Pickup voltage .16

8.4.3 Dropout voltage .16

8.5 Electrical characteristics .16

8.5.1 General.16

8.5.2 Contact voltage drop.17

8.5.3 Quiescent power dissipation .17

8.5.4 Control signals .17

8.6 Contact bounce, operating and release times .19

8.7 Dielectric withstanding voltage .21

8.8 Insulation resistance .21

8.9 Overloads .21

8.9.1 Trip characteristics with the overload condition .21

8.9.2 Circuit breaker compatibility .22

8.10 Ground Fault Interrupt characteristics .22

8.11 Trip-free characteristics.22

8.12 Life .22

8.13 Terminal strength .22

8.14 Seal .23

Bibliography .24

iv © ISO 2018 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see www .iso

.org/iso/foreword .html.

This document was prepared by Technical Committee ISO/TC 20, Aircraft and space vehicles,

Subcommittee SC 1, Aerospace electrical requirements.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/members .html.

A list of all parts in the ISO 20949 series can be found on the ISO website.

Introduction

This document provides general requirements of the smart contactor for aircraft.

Smart Contactor based power distribution systems are emerging among advanced aircraft applications,

especially among More Electric Aircraft and All Electric Aircraft. Standardization is increasingly

needed for Smart Contactors in aircraft power systems based on intelligent high current switching

and protecting technology. Those systems have the potential for higher reliability and longer operating

life, with higher capability for status sensing, over-current protection, lower maintenance costs, higher

flexibility of designing power switching as well as protecting performance compared with conventional

contactor switched systems.

The purpose of this document, the definitions of smart contactor and the contents of the document are

as follows:

a) The purpose of this document:

1) To standardize the requirements for smart contactors that are physically and environmentally

diversified.

2) To provide the applicable document for various smart contactors.

b) The definitions of smart contactor:

1) Consists of an intelligent circuit and a power switch.

2) Turns on/off the power output by receiving the control signal.

3) Detects the over current in the load which results in shutting down for this current.

4) Indicates the on/off status of the power output.

5) Reports the status of smart contactor.

c) The contents of this document:

1) Definitions of the technical terms.

2) Electrical requirements.

3) Test methods.

In order to satisfy the purpose of this document, requirements such as physical, environmental and

individual items are specified in accordance with the detail requirements that are issued individually.

vi © ISO 2018 – All rights reserved

INTERNATIONAL STANDARD ISO 20949:2018(E)

Aircraft — Smart contactor — General requirements

1 Scope

This document specifies the definitions, titles of design and general requirements and test methods to

determine the performance of smart contactors for use in aircraft electrical power systems. The smart

contactor consists of a switching driving circuit and a power switch for protection, action on control

signals, and providing status information.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 1540, Aerospace — Characteristics of aircraft electrical systems

ISO 2678:1985,Environmental tests for aircraft equipment — Insulation resistance and high voltage tests

for electrical equipment

ISO 7137:1995,Aircraft — Environmental conditions and test procedures for airborne equipment

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http: //www .electropedia .org/

— ISO Online browsing platform: available at https: //www .iso .org/obp

3.1

bounce time

for a contact which is closing (opening) its circuit, the time interval between the instant when the

contact circuit first closes (opens) and the instant when the circuit is finally closed (opened)

3.2

contact bounce

intermittent opening of contacts after initial closure due to contact impact

3.3

control signals

signals including control or status which is specified for operation of the smart contactor, i.e. voltage

supply, control signals including turn on/off, switch status, and/or communication signals, or other

3.4

load voltage

voltage between the power output terminal of the smart contactor and the power ground

3.5

off state

condition which, with the turn-off signal applied, the device prevents power from being passed to the load

3.6

on state

condition which, with the turn-on signal applied, the device allows power to be passed to the load

3.7

peak let-through current

peak value of the current at maximum system voltage that the smart contactor will conduct for a

specified time interval without damage

3.8

power dissipation

power dissipation which includes all power dissipated in the power switching circuit, power losses due

to internal leakage currents, and power supplies

Note 1 to entry: When the smart contactor is OFF, the power dissipation includes only dissipation due to leakage

currents and internal power supplies.

3.9

reset

restoration of the tripped smart contactor to a state from which it can be turned ON

3.10

rupture current

maximum current the power circuit is capable of interrupting at maximum system voltage without

damage

3.11

short circuit

circuit with the impedance of less than 1 mΩ applied between the output terminal and ground

3.12

short-circuit current

maximum current that the power circuit will pass without damage for a specified maximum time under

the most adverse combination of electrical and environmental conditions

3.13

smart contactor

device consisting of an intelligent circuit and a power switch

Note 1 to entry: The contactor provides a power switch for high current from its power supply to its load terminal

when in the ON state and a high impedance in the OFF state. The intelligent circuit consists of a driving circuit

to drive the contactor, a detecting circuit sensing the current in the load and intelligent core circuit with but not

limited to programmable signal processing, programmable protection characteristics, commutating capability

that can trip, report device status, provide command to driving circuit in accordance with the control signal and

the on/off status.

Note 2 to entry: The state of the power switch normally conforms to that represented by the last command signal

applied to the smart contactor.

— The smart contactor reverts to the OFF state on detection of an electrical overload or other specified

condition. A resetting operation is required to terminate the trip state. Trip-free action prevents the ON state

being held in the presence of an overload trip condition.

— The state of the power switch is represented by an indication signal supplied by the smart contactor.

3.14

supply voltage

voltage applied between the power input terminal of the smart contactor and the power ground

3.15

switch status

indication showing the actual state of the smart contactor (ON state or OFF state)

2 © ISO 2018 – All rights reserved

3.16

trip

automatic reversion to the OFF state of the smart contactor output caused by an overload condition

3.17

trip curve

curve which sets the minimum and maximum trip points of the smart contactor and is plotted as

current versus time

3.18

trip free

feature which will prevent subsequent re-closing unless preceded by a reset signal, when the smart

contactor has tripped due to an over current condition

3.19

trip time

time interval between the application of an over current condition and the 10 % value of rated

output current

Note 1 to entry: In general, the higher is the over current condition the shorter is the trip time.

3.20

turn-off signal

control signal level at which the smart contactor is turned OFF.

3.21

turn-off time

time interval between initiation of turn-off signal and the time when the output reach 10 % of its

steady-state ON value

3.22

turn-on signal

control signal level at which the smart contactor is turned ON

3.23

turn-on time

time interval between initiation of turn-on signal and the time when the output reach 90 % of its

steady-state ON value

3.24

unwanted trip

tripping function in response to a condition that is not an over-current protection but a condition that

occurs as part of the normal or anticipated operation of circuit components

Note 1 to entry: Nuisance trip is synonymous with unwanted trip.

3.25

voltage drop

voltage across input and output terminals of the smart contactor in the ON state at the specified load

4 General requirements

4.1 Detail specification sheets

The device manufacturer shall prepare an individual specification sheet for each type of device

produced. The individual specification sheet shall define the value for parameters.

4.2 Materials

Materials shall be used which will enable the smart contactors to meet the performance requirements

of this document.

Materials used shall not support combustion, give off noxious gases in harmful quantities, give off gases

in quantities sufficient to cause explosion of sealed enclosures, cause functional contamination of any

part of the smart contactor, or form unintended current-carrying tracks when subjected to any of the

tests specified herein.

4.3 Construction

Smart contactors shall be of design, construction, minimum mass and physical dimensions compatible

with requirements. Smart contactors shall be designed so as to ensure proper operation when mounted

in any attitude.

The construction of the smart contactors shall preclude mechanical damage, flaking of finish, loosing of

terminals, or deterioration of marking when subjected to the test methods of this document.

4.4 Terminals

4.4.1 Main terminals

4.4.1.1 General

There are two acceptable types of terminal as follows.

4.4.1.2 Stud terminals (threaded)

These terminals shall accept connections using aircraft-approved crimped-type lugs. A flat washer

having a diameter at least equal to that of the base of the terminal, and a standard nut with suitable

locking washer shall be used on each terminal. Suitable insulation barriers shall be placed between the

terminals in order to prevent an accidental short circuit. The height and extent of these barriers shall

be sufficient to prevent the short-circuiting of any adjacent terminals through the presence over these

partitions of a flat conducting part.

No rotation or other loosening of a terminal, or any fixed portion of a terminal, shall be caused by

material flow or shrinkage, or any mechanical force (specified in Tables 1 and 2) involved in connection

or disconnection, throughout the life of the smart contactor.

The equivalent metric threads given in Table 2 may be used.

Each terminal shall have a terminal seat that shall provide the normal current-conduction path. The

diameter of the seat shall not be less than the area necessary to assure that the current density does not

exceed l,55 A/mm . The seat does not include the cross-sectional area of the stud.

Stud terminals shall be capable of accommodating two crimped-type lugs, with hardware as specified.

A minimum of one and a half threads shall remain above the nut, with all parts tightened in place.

4.4.1.3 Plug-in terminals

Plug-in terminals, where applicable, shall conform to the dimensions and requirements necessary for

proper mating with the associated sockets.

Units shall have the electrical and environmental tests performed with the associated socket or

connector assembled to the unit.

4 © ISO 2018 – All rights reserved

Table 1 — Strength of threaded terminals (Static value of pull and torque)

Force Installation torque Design torque

Thread designation

N lbf N·m lbf-in N·m lbf-in

No. 4-40 UNC 22,2 5 0,3 2,4 0,5 4,4

No. 6-32 UNC 133,4 30 0,5 4,5 1,1 10

No. 8-32 UNC 155,7 35 1 9 2,3 20

No. 10-32 UNF 177,9 40 1,7 14,5 3,7 32

No. 10-24 UNC 177,9 40 1,8 16 4 35

1/4-28 UNF 222,4 50 3,9 34 8,6 75

5/16-24 UNF 311,4 70 5,2 45 11,5 100

3/8-24 UNF 444,8 100 7,8 68 17,3 150

7/16-20 UNF 444,8 100 7,8 68 17,3 150

1/2-20 UNF 444,8 100 7,8 68 17,3 150

1) See Reference [ ].

Table 2 — Strength of threaded terminals — Metric units (Static value of pull and torque)

Force Installation torque Design torque

Thread designation

N lbf N-m lbf-in N·m lbf-in

M2,5 22,2 5 0,3 2,4 0,5 4,4

M3 133,4 30 0,5 4,5 1,1 10

M4 155,7 35 1 9 2,3 20

M5 177,9 40 1,8 16 4 35

M8 311,4 70 5,2 45 11,5 100

M10 444,8 100 7,8 68 17,3 150

M12×1,25 444,8 100 7,8 68 17,3 150

M14×1,25 444,8 100 7,8 68 17,3 150

NOTE There is no direct metric equivalent to the thread size l/4-28 UNF. M7 would correspond but is not used.

4.4.2 Auxiliary terminals

The auxiliary circuits and control/status connections may be connected by stud, plug-in or connector

terminals to the appropriate specification.

4.5 Enclosures

4.5.1 General

The enclosure design is identified by a single digit, in accordance with Table 3.

Table 3 — Enclosure design

Type Enclosure

1 Open

2 Enclosed (ventilated, explosion-proof)

3 Sealed (other than hermetically)

4 Hermetically sealed

4.5.2 Open enclosures

Type 1 smart contactors shall be uniformly coated on all surfaces with the exception of the mounting

and terminals.

4.5.3 Enclosed enclosures (ventilated explosion-proof)

Unsealed units shall be totally enclosed for mechanical and dust protection and shall be explosion-proof.

4.5.4 Sealed (other than hermetically) enclosures

Environmentally sealed enclosures shall be constructed by any means other than that defined under

hermetically sealed enclosures to achieve the degree of seal specified. Environmentally sealed units

shall be purged and filled with a suitable gas of such characteristics that the leakage rate may be

determined by conventional means. The units shall be designed to ensure that the essential electrical

performance is not jeopardized in the event of a failure of the environmental seal in service.

4.5.5 Hermetically sealed enclosures

Hermetically sealed enclosures shall be constructed as gas-tight enclosures which have been completely

sealed by fusion of glass or ceramic to metal, or by welding, brazing or soldering of metal to metal.

Hermetically sealed units shall be purged and filled with a suitable inert gas of such characteristics that

the leakage rate may be determined by conventional means.

4.5.6 Grounding of enclosures

The enclosures for type 2, 3 and 4 smart contactors shall be electrically isolated and provide means for

grounding where appropriate.

The mountings shall provide an effective electrical contact to ground when the unit is mounted as

specified. Alternatively, the enclosures shall be provided with a grounding connection such as a

terminal or lug.

The covers shall be rugged in design, constructed of high-impact materials and securely mounted to the

unit. Metal covers shall be provided with a means of grounding.

4.6 Installation clearances

Adequate clearance shall be provided for the installation of terminals mounting hardware. Clearance for

socket wrenches shall be provided, where appropriate. Special installation tools shall not be required.

4.7 Terminal marking

Stud terminal identification shall be durable and legibly marked.

4.8 Terminal covers and barriers

The unit shall be provided with adequate covering or separation of terminal parts to provide protection

against inadvertent shorting, grounding, or contact by personnel. Barriers may be removable or may be

integral with removable covers.

Terminal covers and barriers shall be designed to meet performance requirements applicable to the

unit. The enclosure(s) shall be so designed that when the cover is removed, the smart contactor shall be

capable or operating without adjustment.

The cover design shall be such that pressure differentials cannot exist between the inside and outside.

6 © ISO 2018 – All rights reserved

4.9 Mounting

No rotation or other loosening of a stud, or any fixed portion of a stud, shall be caused by material flow

or shrinkage, or by any mechanical forces (as specified in Table 4) involved in mounting or demounting,

throughout the life of the smart contactors.

Table 4 — Strength of threaded mounting studs (Static value pull and torque)

Force Torque

Thread size designation

N Ibf N·m Ibf·in

No. 4-40 UNC 31,1 7 1,1 10

No. 6-32 UNC 111,2 25 2 18

Mo. 8-32 UNC 155,7 35 4,2 37

No. 10-32 UNF 222,4 50 6,8 60

1/4-28 UNF 266,9 60 11,3 100

5/16-24 UNF 355,9 80 18,1 160

3/8-24 UNF 511,5 115 31,1 275

7/16-20 UNF 622,8 140 53,7 475

5 Design characteristics

5.1 General

5.1.1 Smart contactors provide both control and protection functions (as well as status feedback

information).

5.1.2 The smart contactor shall incorporate a current-sensing means to measure output current

flow and to detect specified over-currents. The smart contactor should incorporate specified trip-time

characteristics.

5.1.3 Up to a specified fault-current level, the device shall follow a defined trip characteristic. Above

this level, the device shall current-limit or provide a near instantaneous trip.

5.1.4 After the smart contactor has tripped on overcurrent, it shall exhibit a trip-free characteristic

remaining in the OFF state (and providing trip status information) until reset.

5.1.5 Reset is accomplished by cycling the control input from ON to OFF and then back to ON, or

employing a dedicated RESET (auxiliary) input.

5.1.6 In the event of repeated attempts to switch into a fault, the smart contactor shall not be damaged.

In order to prevent damage to associated wiring, as well as the overheating of the smart contactor, a

working pattern for switching into various overload conditions shall be specified.

5.1.7 The smart contactor shall meet the specified stabilization times after power-up, after a

momentary power outage and during a supply voltage drop due to a fault, until the smart contactor

opens, clearing the fault and allowing supply voltage recovery.

5.1.8 The smart contactor shall incorporate BIT means to determine the important part including

intelligent circuit, power switch and transducer normal or abnormal.

5.2 Control signal

Each smart contactor shall be designed to operate from one of the following types of input signal.

a) Nominal voltage 28 V d.c.

b) Grounded smart contactor input to switch smart contactor ON; in the ON state the impedance seen

by the input control shall not exceed 600 Ω.

c) Logic level signal for interfacing to a control bus (TTL or CMOS).

d) 10 mA source at 1 V to 12 V to switch smart contactor ON. This allows compatibility with existing

circuit breakers.

5.3 Status signals for smart contactors

As a minimum, one status signal shall be provided. The preferred status signals are switch status and/

or current-flow status.

5.4 Fail-safe characteristics

When a fail-safe feature is incorporated, its characteristics shall be specified. When tested, the fail-safe

element shall open the circuit at specified currents and times.

6 Operating characteristics

6.1 General operating characteristics

When tested as specified in Clause 8, the smart contactor shall operate with supply voltage variations

in accordance with ISO 1540 or the detail requirements, and the smart contactor shall be capable of

controlling all type of loads as required by the detail requirements.

All smart contactors shall function satisfactorily over the full specified range of applied electrical and

mechanical steady-state and transient conditions.

6.2 Timing sequence

The timing sequence shall be as specified in Figure 1.

8 © ISO 2018 – All rights reserved

Figure 1 — Timing sequence diagram

6.3 Operating voltage

6.3.1 General

The operating voltage of Smart Contactor shall guarantee Smart Contactor turn on or turn off reliably

in specified working range.

6.3.2 Pickup voltage

When smart contactors are tested in accordance with 8.4.2, each set of contacts shall make positive

contact or open, as applicable, in the energized position when a potential voltage not in excess of the

specified pickup voltage is applied to the contactor coil. All normally open switching circuits shall close

with positive contact and all normally closed circuits, if applicable, shall open. Once the device has

picked up, the contacts shall not change state (break and remake) when the coil voltage is increased

from the point of pickup to the maximum coil voltage, excluding normal contact bounce. For qualification

inspection, the pickup voltage shall fall within the maximum specified when the contactor is mounted

in each of three mutually perpendicular planes.

6.3.3 Dropout voltage

When smart contactors are tested in accordance with 8.4.3, each set of normally open contacts shall

open, and each set of normally closed contacts shall close as applicable, when the applied coil voltage is

in the specified dropout voltage range. Excluding normal contact bounce, once the device has dropped

out, the contacts shall not change state when the voltage is reduced from the point of dropout to 0 V.

For qualification inspection, the dropout voltage shall be measured with the device in each of three

mutually perpendicular planes.

6.4 Electrical characteristics

6.4.1 General

Smart contactors shall be capable of making, carrying and breaking all values of load current up to the

rated short-circuit fault level.

Smart contactors shall be self-protecting with respect to fault-current level and incorporate suppression

for operating coil voltage spikes. Semiconductor devices shall be adequately protected from smart

contactors-generated and external transients.

Smart contactors shall, as a minimum requirement, protect their associated connecting cables from

damage.

6.4.2 Contact voltage drop

When smart contactors are tested in accordance with 8.5.2, the voltage drop values measured at the

appropriate terminal with rated resistive current shall not exceed the values given in Table 5.

Table 5 — Contact voltage drop

Voltage drop, mV

Terminals Rated current strength

Initial After endurance tests

Main contacts Same rating as contactor 150 175

Auxiliary Contacts 5A (or as rated) 100 180

When a connector is used for connecting the auxiliary circuits, the voltage drop value shall be increased

by amount permitted for the connector.

6.4.3 Quiescent power dissipation

The smart contactor power dissipation in the OFF-state for a normally open device, or in the ON-state

for a normally closed device, shall be a minimum.

6.4.4 Control signals

6.4.4.1 General

The control signals of smart contactor shall be in accordance with ISO 1540 and with specified detail

specification.

6.4.4.2 Control power supply current

When tested as specified in 8.5.4.1, the control power supply current shall be as specified in the detail

requirements.

6.4.4.3 Transient voltage

When tested as specified in 8.5.4.2, the transient voltage shall be as specified in the detail requirements.

6.4.4.4 Status turn-off time

When tested as specified in 8.5.4.3, the status turn-off time shall be as specified in the detail

requirements.

6.4.4.5 Status turn-on time

When tested as specified in 8.5.4.4, the status turn-on time shall be as specified in the detail

requirements.

6.4.4.6 Turn-off voltage

When tested as specified in 8.5.4.5, the turn-off voltage shall be as specified in the detail requirements.

10 © ISO 2018 – All rights reserved

6.4.4.7 Turn-on voltage

When tested as specified in 8.5.4.6, the turn-on voltage shall be as specified in the detail requirements.

6.4.4.8 Control current

When tested as specified in 8.5.4.7, the control current shall be as specified in the detail requirements.

6.5 Contact bounce, operating and release time

Photographic records of contact operating and release times, and contact bounce at nominal coil voltage

shall be taken for qualification test approval.

When smart contactors are tested in accordance with 8.6, the contact bounce operating and release

times shall be within limits specified in the detail specification (see 4.1). The operating and release

times shall not include the contact bounce time. The operating time and release time of each pole of

a multiple relay shall be within 1 ms of each other pole of that relay for relays with contact ratings of

15 A or less, and within 2 ms for smart contactors with contact ratings greater than 15 A. Synchronized

switching control parameters for auxiliary contacts relative to main and each other shall be specified

in the detail specification. Unless make-before-break action is specified in the detail specification.

Double-throw smart contactors shall show no evidence of any normally open contacts closing before all

normally closed contacts open; any normally closed contacts shall not make before all normally open

contacts break. Contact break bounce on release of normally open contacts when specified in the detail

specification shall be less than 100 μs.

6.6 Dielectric strength

Unless otherwise specified, tests shall be carried out in accordance with ISO 2678:1985, 4.1. The

insulation of the devices shall be capable of withstanding without damage. The test voltage shall be in

accordance with ISO 2678:1985, 4.1.

All restrictions arising from the semiconductors shall be declared.

Table 6 — Minimum values for high voltage tests

Rated voltage Test voltage Duration

28 V a.c. 500 V, 50 Hz to 60 Hz 1 min

115/200 V a.c. 1 000 V, 50 Hz to 60 Hz 1 min

28 V a.c 600 V, 50 Hz to 60 Hz 5 s to 10 s

115/200 V a.c 1 500 V, 50 Hz to 60 Hz 5 s to 10 s

6.7 Insulation resistance

The requirements for an adequate insulation resistance shall be detailed in the relevant equipment

specification. They shall be deemed to be met when the minimum values of Table 7 are obtained in

accordance with ISO 2678.

Table 7 — Minimum values for insulation resistance

Insulati

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...