ISO 17607-1:2023

(Main)Steel structures — Execution of structural steelwork — Part 1: General requirements and terms and definitions

Steel structures — Execution of structural steelwork — Part 1: General requirements and terms and definitions

This document defines general requirements for the execution of structural steelwork for: — structural steel buildings; — general structures, designed, fabricated, and erected in a manner similar to buildings with building-like load-resisting elements, e.g. support framing for equipment, tanks, vessels, and pipelines; — crane-supporting structures; — typical roadway and pedestrian bridges including those constructed using rolled sections, welded plate girders, or trusses (lattices). This document applies to structures or fabricated components that are produced from: — hot-rolled and cold-formed structural steel products up to and including a nominal yield strength of 700 MPa with a thickness of 3 mm and above; — hot-finished and cold-formed structural steel hollow sections, up to and including a nominal yield strength of 700 MPa, including standard range and custom-made rolled products and hollow sections manufactured by welding. This document also applies to steel components in composite steel and concrete structures, and in structures combining steel with other materials. This document defines requirements independent of the type and shape of the steel structure, including structures subjected to fatigue or seismic loading. The requirements are expressed in terms of execution levels. This document does not define all requirements for other types of fabricated steel structures (e.g. railway bridges, roadway and pedestrian bridges using welded box sections or arch boxes, cable-supported bridges over 100 m span, moving bridges, monorails, steel towers, masts, chimneys, silos, tanks, pipelines, antennae, offshore platforms). However, this document provides general guidance regarding fabrication and erection practices that may be used together with the appropriate ISO, regional or national design standards for such structures. This document does not cover requirements for the following: — sheeting; — fabrication of stainless steels. This document does not apply to design of steel structures. NOTE Design is inextricably a part of the design-fabrication-erection sequence, including the application of tolerances, and cannot be considered in isolation. This document is intended to be used, as appropriate, together with national standards and other documents, observing the provisions in this document concerning such use.

Structures en acier – Exécution des charpentes et ossatures en acier — Partie 1: Exigences générales et termes et définitions

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 17607-1

First edition

2023-12

Steel structures — Execution of

structural steelwork —

Part 1:

General requirements and terms and

definitions

Structures en acier – Exécution des charpentes et ossatures en

acier —

Partie 1: Exigences générales et termes et définitions

Reference number

© ISO 2023

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

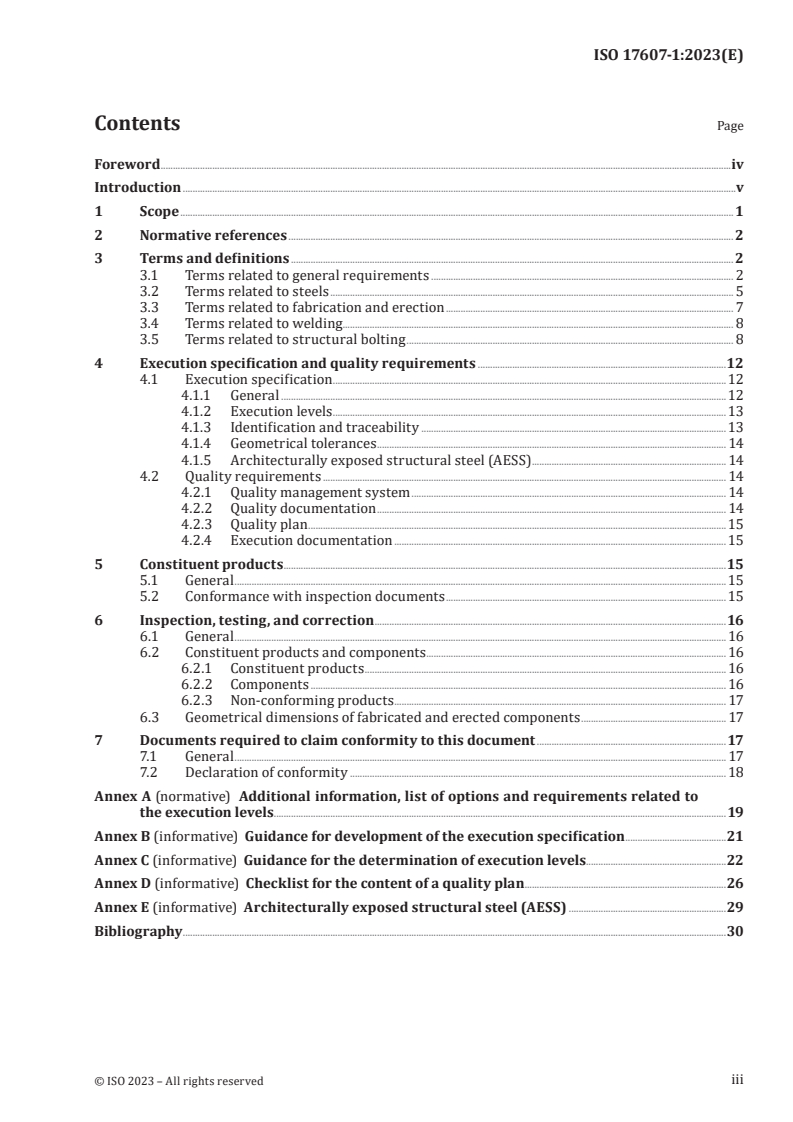

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 2

3 Terms and definitions . 2

3.1 Terms related to general requirements . 2

3.2 Terms related to steels . 5

3.3 Terms related to fabrication and erection . 7

3.4 Terms related to welding. 8

3.5 Terms related to structural bolting . 8

4 Execution specification and quality requirements .12

4.1 Execution specification .12

4.1.1 General .12

4.1.2 Execution levels . 13

4.1.3 Identification and traceability . 13

4.1.4 Geometrical tolerances . 14

4.1.5 Architecturally exposed structural steel (AESS) . 14

4.2 Quality requirements . 14

4.2.1 Quality management system . 14

4.2.2 Quality documentation . 14

4.2.3 Quality plan .15

4.2.4 Execution documentation . 15

5 Constituent products .15

5.1 General . 15

5.2 Conformance with inspection documents . 15

6 Inspection, testing, and correction .16

6.1 General . 16

6.2 Constituent products and components . 16

6.2.1 Constituent products . 16

6.2.2 Components . 16

6.2.3 Non-conforming products . 17

6.3 Geometrical dimensions of fabricated and erected components . 17

7 Documents required to claim conformity to this document .17

7.1 General . 17

7.2 Declaration of conformity . 18

Annex A (normative) Additional information, list of options and requirements related to

the execution levels.19

Annex B (informative) Guidance for development of the execution specification .21

Annex C (informative) Guidance for the determination of execution levels.22

Annex D (informative) Checklist for the content of a quality plan .26

Annex E (informative) Architecturally exposed structural steel (AESS) .29

Bibliography .30

iii

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use

of (a) patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed

patent rights in respect thereof. As of the date of publication of this document, ISO had not received

notice of (a) patent(s) which may be required to implement this document. However, implementers are

cautioned that this may not represent the latest information, which may be obtained from the patent

database available at www.iso.org/patents. ISO shall not be held responsible for identifying any or all

such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 167, Steel and aluminium structures.

This first edition cancels and replaces ISO 10721-2:1999, which has been technically revised.

A list of all parts in the ISO 17607 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

iv

Introduction

Specific requirements for the achievement of structures that are optimal with respect to safety, the

state of the economy, development and general values of a nation are given in the appropriate regional

or national standards, if they exist.

Many nations do not have their own standards for structural steelwork. Some refer to other national

or regional standards. Some permit the project’s standard to be selected by the owner, designer or

constructor of the structure. Some do not require any standards to be followed.

The ISO 17607 series of standards on the execution of structural steelwork was developed to serve

as a means to provide a set of requirements and guidance for projects that are constructed without a

governing regional or national standard. The ISO 17607 series can also serve to reduce trade barriers.

Additional requirements to be addressed in the execution of structural steelwork, as structures or as

fabricated components, can be found in the other parts of the series:

— ISO 17607-2 (Steels);

— ISO 17607-3 (Fabrication);

— ISO 17607-4 (Erection);

— ISO 17607-5 (Welding);

— ISO 17607-6 (Bolting).

v

INTERNATIONAL STANDARD ISO 17607-1:2023(E)

Steel structures — Execution of structural steelwork —

Part 1:

General requirements and terms and definitions

1 Scope

This document defines general requirements for the execution of structural steelwork for:

— structural steel buildings;

— general structures, designed, fabricated, and erected in a manner similar to buildings with building-

like load-resisting elements, e.g. support framing for equipment, tanks, vessels, and pipelines;

— crane-supporting structures;

— typical roadway and pedestrian bridges including those constructed using rolled sections, welded

plate girders, or trusses (lattices).

This document applies to structures or fabricated components that are produced from:

— hot-rolled and cold-formed structural steel products up to and including a nominal yield strength of

700 MPa with a thickness of 3 mm and above;

— hot-finished and cold-formed structural steel hollow sections, up to and including a nominal yield

strength of 700 MPa, including standard range and custom-made rolled products and hollow

sections manufactured by welding.

This document also applies to steel components in composite steel and concrete structures, and in

structures combining steel with other materials.

This document defines requirements independent of the type and shape of the steel structure,

including structures subjected to fatigue or seismic loading. The requirements are expressed in terms

of execution levels.

This document does not define all requirements for other types of fabricated steel structures (e.g.

railway bridges, roadway and pedestrian bridges using welded box sections or arch boxes, cable-

supported bridges over 100 m span, moving bridges, monorails, steel towers, masts, chimneys, silos,

tanks, pipelines, antennae, offshore platforms). However, this document provides general guidance

regarding fabrication and erection practices that may be used together with the appropriate ISO,

regional or national design standards for such structures.

This document does not cover requirements for the following:

— sheeting;

— fabrication of stainless steels.

This document does not apply to design of steel structures.

NOTE Design is inextricably a part of the design-fabrication-erection sequence, including the application of

tolerances, and cannot be considered in isolation.

This document is intended to be used, as appropriate, together with national standards and other

documents, observing the provisions in this document concerning such use.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 6707-1, Buildings and civil engineering works — Vocabulary — Part 1: General terms

ISO 6707-2, Buildings and civil engineering works — Vocabulary — Part 2: Contract and communication

terms

ISO 7976-1, Tolerances for building — Methods of measurement of buildings and building products — Part

1: Methods and instruments

ISO 7976-2, Tolerances for building — Methods of measurement of buildings and building products — Part

2: Position of measuring points

ISO/TR 25901-1, Welding and allied processes — Vocabulary — Part 1: General terms

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 6707-1, ISO 6707-2 and

ISO/TR 25901-1 and the following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1 Terms related to general requirements

3.1.1

structure

organized combination of connected parts designed to carry loads and provide rigidity, redundancy,

and structural stability

3.1.2

structural steelwork

steel structures or fabricated steel components used in construction works (3.1.4)

3.1.3

architecturally exposed structural steel

AESS

structural steelwork (3.1.2) exposed to view with additional requirements specified to achieve

designated aesthetic qualities

3.1.4

construction works

everything that is constructed or results from construction operations

Note 1 to entry: This term covers both building and civil engineering works. It refers to the complete construction

comprising both structural and non-structural components.

3.1.5

constructor

person or organization executing the structural steelwork (3.1.2)

Note 1 to entry: Multiple constructors may be involved in a project.

Note 2 to entry: The term constructor includes fabricator and erector.

Note 3 to entry: In ISO 9000, the term "supplier" (3.1.7) is used.

3.1.6

manufacturer

organization that manufactures the respective products according to the requirements of the order

and to properties specified in the referenced product specification or execution specification (3.1.10)

Note 1 to entry: As used in this document, the term manufacturer does not include the organization performing

fabrication (3.1.9), which is termed the constructor (3.1.5).

[SOURCE: ISO 10474:2013, 3.4, modified, — Added reference to execution specification.]

3.1.7

supplier

organization that is supplied with products by the manufacturers (3.1.6) and that then, in turn, supplies

them without further processing or after processing without changing the properties specified in the

purchase order, the referenced product specification or execution specification (3.1.10)

Note 1 to entry: Examples of suppliers can be steel service centres and stockists.

[SOURCE: ISO 10474:2013, 3.5, modified — Changed term from intermediary to supplier, added

reference to execution specification.]

3.1.8

execution

all activities performed for the physical completion of the structural steelwork (3.1.2), i.e. procurement,

fabrication (3.1.9), welding, bolting, transportation, erection, and the inspection and documentation

thereof

3.1.9

fabrication

DEPRECATED: manufacturing

all activities required to produce and deliver a component

Note 1 to entry: As relevant, this comprises, e.g. procurement, preparation (3.3.9) and assembly, welding, bolting,

transportation, and the inspection and documentation thereof.

3.1.10

execution specification

set of documents covering technical data and requirements for a particular steel structure, including

those specified to supplement and qualify the rules of this document

Note 1 to entry: Execution specification includes requirements where this document identifies items to be

specified.

3.1.11

specifier

organization, firm, agency, or individual responsible for development and maintenance of the execution

specification (3.1.10)

3.1.12

execution level

classified set of requirements specified for the execution of the structural steelwork (3.1.2) as a whole,

of an individual component or a detail of a component

Note 1 to entry: Execution level is similar to, but not necessarily identical to, execution classes in other standards.

Note 2 to entry: Execution levels are described in Annex A and Annex C, Table C.1 and Table C.2.

3.1.13

constituent product

material and product used for fabricating a sub-component (3.1.18) or component (3.1.16) and which

remains as part of it

EXAMPLE Steel product (3.1.14), bolting product, welding consumable.

3.1.14

steel product

constituent product (3.1.13) supplied as hot-rolled or cold-formed steel shapes, plates or bars, or as hot-

finished or cold-formed steel hollow sections

3.1.15

inspection document

document, issued by the manufacturer (3.1.6), or supplier (3.1.7) if applicable, and supplied to the

purchaser, of the constituent product (3.1.13) that describes properties of supplied constituent product

in a way that enables it to be compared to the specified properties

Note 1 to entry: For further information, see ISO 10474 for steels and steel products (3.1.14) and ISO 16228 for

bolting and fastener products.

EXAMPLE 1 Manufacturer's certificate of compliance, manufacturer's test report, material test report.

EXAMPLE 2 Declaration of compliance 2.1, test report 2.2, or inspection certificates 3.1 and 3.2 for the

material.

3.1.16

component

shipping piece

shipping member

erectable part of a steel structure, which can itself be an assembly of several sub-components (3.1.18)

3.1.17

main component

primary load-carrying steel component

Note 1 to entry: Main components can be identified in the execution specification (3.1.10).

Note 2 to entry: This excludes sub-components.

EXAMPLE Beam, girder. column, bracing, truss.

3.1.18

sub-component

constituent product (3.1.13) that is transformed or fabricated to be incorporated into a fabricated

component or into the erected steel structure

EXAMPLE Connection (3.5.14) detail, stiffener, curb angle.

3.1.19

identification

ability of recognizing, by way of suitable tagging, tracking, marking or other means, the identity of a

specific piece or pieces, products, processes, procedures or personnel

3.1.20

identification means

descriptive matter, including tags, words, particulars, trademarks, brand name, pictorial matter,

symbols, or other methods referring to constituent product (3.1.13), process, or personnel, written,

printed, stencilled, marked, embossed or impressed on, or attached to a piece or component and

referenced in the constructor's (3.1.5) documentation

3.1.21

identification document

set of data enabling the identity of constituent product (3.1.13), process, or personnel

EXAMPLE Inspection documents (3.1.15), material test reports, heat treatment documents, welding

procedure specifications, welder and welding operator certificates.

3.1.22

traceability

process and ability of associating product, process, procedure, or personnel back to non-specific data

related to the respective family of either products or relevant fabrication (3.1.9) processes, or both, e.g.

inspection documents (3.1.15) or identification marks

Note 1 to entry: Additional information and levels of traceability are given in C.3.

3.1.23

lot traceability

process and ability of associating product, process, procedure, or personnel back to specific data related

to an individual lot of either products or individual fabrication (3.1.9) processes, or both, e.g. specific

inspection documents (3.1.15) or individual lot identification marks

3.1.24

quality plan

document or set of documents that describes the standards, quality practices, resources and processes

pertinent to a specific product, service or project

3.1.25

inspection and test plan

ITP

document providing the type and sequence of inspections and tests, including appropriate resources,

procedures and other relevant information

Note 1 to entry: Inspection and test plans may be presented as a single document or as a series of interdependent

or supporting documents.

3.1.26

inspector

party responsible to ensure that the constructor (3.1.5) has satisfied the requirements stated in the

execution specification (3.1.10) in the work

3.1.27

inspection report

document prepared by an inspector (3.1.26) of materials, fabrication (3.1.9), erection, welding, or bolting,

according to an inspection and test plan (3.1.25) that describes conformance or non-conformance with

specified requirements

3.1.28

nonconformity

non-fulfilment of a requirement

[SOURCE: ISO 9000:2015, 3.6.9, modified — Deleted Note 1 to entry.]

3.2 Terms related to steels

3.2.1

as-rolled steel

steel without any special rolling and/or heat treatment condition

Note 1 to entry: Adapted from ISO 630-6:2014, 3.1.

3.2.2

normalized steel

steel produced by heating to a suitable temperature above the transformation range and then cooling in

air to a temperature substantially below the transformation range

Note 1 to entry: For structural steel hollow sections, the definition for normalizing in ISO 4885 may be used.

Note 2 to entry: Adapted from ISO 630-6:2014, 3.2.

3.2.3

quenched steel

steel subjected to cooling more rapidly than in still air from a high temperature above Ac1

Note 1 to entry: Ac1 is the temperature at which austenite begins to form during heating.

Note 2 to entry: Adapted from ISO 630-6:2014, 3.3.

3.2.4

tempered steel

steel subjected to heat treatment, generally after quench hardening or another heat treatment to bring

the properties to the required level, and consisting of heating to specific temperatures (< Ac1) and

soaking for an appropriate duration followed by cooling at an appropriate rate

Note 1 to entry: Additionally, the following may apply: processes of direct quenching plus tempering.

Note 2 to entry: Adapted from ISO 630-6:2014, 3.4.

3.2.5

thermomechanical processed steel

steel rolled with a process in which the final deformation is carried out in a certain temperature range

leading to a material condition with certain properties which cannot be achieved or repeated by heat

treatment alone

Note 1 to entry: Hot forming or post-weld heat treatment above 580 °C can lower the strength values and should

not be performed. Flame straightening may be applied in accordance with relevant technical recommendations.

Note 2 to entry: Thermomechanical rolling can include processes with an increasing cooling rate with or without

tempering, including self-tempering but excluding direct quenching and quenching and tempering.

Note 3 to entry: In some publications, the term “Thermomechanical Control Process” is also used.

Note 4 to entry: Adapted from ISO 630-6:2014, 3.5.

3.2.6

atmospheric corrosion resistant steel

steel with the ability to resist degradation or alteration of material through chemical reaction with the

surrounding atmosphere

Note 1 to entry: Adapted from ASTM A941: 2017, 3, atmospheric corrosion resistance.

3.2.7

cold formed component

cold formed long products or profiled sheet having various cross-section shapes, either open or with

edges abutting, constant along their length, made from coated or uncoated hot or cold rolled flat

products whose thicknesses are only slightly modified by the cold forming process (e.g. profiling,

drawing, press forming, flanging)

[SOURCE: EN 1090-2:2018, 3.9.1]

3.3 Terms related to fabrication and erection

3.3.1

tolerance

difference between the upper limit of size and the lower limit of size

Note 1 to entry: Tolerance is an absolute value without sign.

Note 2 to entry: In building construction, tolerance is commonly expressed by “± permitted deviation” so that the

value of the tolerance is implicit.

[SOURCE: EN 1090-2:2018, 3.15, modified — Note 2 to entry was added.]

3.3.2

fabrication tolerance

manufacturing tolerance

permitted range in the size or dimensions of a component resulting from component fabrication

3.3.3

erection tolerance

permitted range in the position of an erected component

3.3.4

essential tolerance

basic limits for a geometrical tolerance necessary to satisfy the design assumptions for structures in

terms of mechanical resistance and stability

[SOURCE: EN 1090-2:2018, 3.15.1]

3.3.5

functional tolerance

geometrical tolerance which may be specified to meet a function other than mechanical resistance and

stability, e.g. appearance or fit up

[SOURCE: EN 1090-2:2018, 3.15.2]

3.3.6

special tolerance

geometrical tolerance which is not covered by the tabulated types or values of tolerances given in this

document, and which needs to be specified in a particular case

[SOURCE: EN 1090-2:2018, 3,15,3, modified — Removed reference to European standard.]

3.3.7

limit tolerance

maximum or minimum value for the acceptance criteria that shall not be exceeded

[40]

[SOURCE: JASS 6, Appendix 6]

3.3.8

control tolerance

target value used as a criterion for fabrication or erection so that 95% or more of the products can be

accepted based on receiving inspection for dimensional accuracy

Note 1 to entry: An accepted value used to judge whether the inspection lot can be accepted or rejected.

[40]

[SOURCE: JASS 6, Appendix 6]

3.3.9

preparation

all activities performed on the constituent steel products (3.1.14) to produce the parts ready for

assembly and inclusion in components

Note 1 to entry: As relevant, this comprises, e.g. identification, handling and storage, cutting, shaping and holing.

Note 2 to entry: Not as applied to preparation of steel substrates for the application of coatings.

3.3.10

design basis procedure for erection

design erection sequence

outline of a procedure for erection upon which the design of the structure is based

3.3.11

erection procedure

documentation describing the procedures to be used to erect a structure

3.3.12

trial assembly

putting together sufficient components of a whole structure to check that they fit

3.4 Terms related to welding

3.4.1

prefabrication primer

shop primer

primer that is applied to materials and may or may not be removed prior to any fabrication activities

(e.g. cutting, welding) being performed

3.4.2

supplementary non-destructive testing

supplementary NDT

non-destructive testing (NDT) technique which is other than visual inspection (VT)

EXAMPLE Magnetic particle (MT), penetrant (PT), eddy current (ET), ultrasonic (UT) or radiographic (RT)

testing.

Note 1 to entry: VT, MT, PT, ET, UT, RT are defined in ISO 17635.

3.5 Terms related to structural bolting

3.5.1

high-strength bolt

bolt with a property class of 8.8 or higher, or with a tensile strength of 830 MPa or higher, used for

structural purposes

3.5.2

washer

component of a bolting assembly (3.5.4) that accepts a bolt through its centre hole

Note 1 to entry: A washer is typically plain or chamfered.

Note 2 to entry: A washer provides a surface to distribute bearing stress and provides a hardened surface for

head or nut rotation during tightening.

Note 3 to entry: Adapted from ASTM F1789 -17a: 2017, 3, plain washer.

3.5.3

pin

unthreaded fastener

3.5.4

bolting assembly

bolt, nut and washer(s) as necessary, that is installed as a unit

Note 1 to entry: The bolt, nut and washer(s) may be sourced from different manufacturers (3.1.6).

3.5.5

matched bolting assembly

matching bolt, nut and washer(s) as necessary, that is supplied, tested and installed as a unit

Note 1 to entry: The bolt, nut and washer(s) may be sourced from different manufacturers (3.1.6).

3.5.6

manufacturing lot

quantity of structural bolting components of a single designation including product grade, property

class and size, manufactured from bar, wire, rod or flat product from a single cast, processed through

the same or similar steps at the same time or over a continuous time period, and through the same heat

treatment or coating process, if any

3.5.7

assembly lot

bolting assemblies supplied together as a set comprising:

— bolts from a single manufacturing lot (3.5.6);

— nuts from a single manufacturing lot;

— washers from a single manufacturing lot.

3.5.8

extended assembly lot

assembly lot containing the component with the main influence on the result of the suitability test from

a single manufacturing lot (3.5.6) and the other components from several manufacturing lots

Note 1 to entry: The component having the main influence (either nut or direct tension indicator) is determined

on the basis of test results.

Note 2 to entry: An extended bolting assembly lot contains bolts, nuts and washers and, if relevant, direct tension

indicators and nut face washers or bolt face washers.

3.5.9

bolt group

bolting assemblies of the same origin in similar connections (3.5.14) with the bolting assemblies of the

same size and property class

Note 1 to entry: This term is used for purposes of inspection.

3.5.10

special fastener

fastener that is not covered by international or national standards

3.5.11

non-slip fastener

fastener that does not allow slip to occur between connected plates or members at the serviceability

limit state so that the original alignment and relative positions are maintained, even without pretension

EXAMPLE Pins (3.5.3), fit bolts.

3.5.12

k-factor

relationship between the applied tightening torque, M, and the achieved pretension, F

k = M / (F × d)

where d is the nominal diameter of the bolting assembly (3.5.4)

3.5.13

k-class

value used to express the ability of a bolting assembly to be pretensioned by a method that relies upon

the application of a specific torque

Note 1 to entry: k-class is as specified in EN 14399-1:2015, 4, 5, and Table 1.

Note 2 to entry: k-class K0 indicates no requirements for k-factor (3.5.12); K1 indicates individual test value

between 0,10 and 0,16, inclusive; K2 indicates mean test value between 0,10 and 0,23, inclusive, and coefficient of

variation of k-factor (3.5.12) less than or equal to 0,06.

3.5.14

connection

joint

location where sub-components (3.1.18) and components are joined

Note 1 to entry: The term joint is more commonly used to describe the type or behaviour of a connection.

3.5.15

bearing-type joint

shear/bearing joint

joint using either non-pretensioned bolts, or high-strength bolts (3.5.1) tightened to induce a specified

minimum bolt pretension, in which the design action is transferred by shear in the bolts and bearing on

the connected parts at the strength limit state

3.5.16

pretensioned joint

joint that transmits shear or tensile loads, or both, in which the bolts have been installed to provide a

specified pretension in the installed bolt

3.5.17

non-pretensioned joint

snug-tight joint

joint in which the bolts have been installed to achieve the snug-tight condition, without requirements to

provide a specified pretension in the bolt, in which the design action is transferred by shear in the bolts

and bearing on the connected parts at the strength limit state

3.5.18

snug-tight condition

condition that exists when all of the plies in a connection (3.5.14) have been pulled into firm contact

(3.5.26) by the bolts in the joint and all of the bolts in the joint have been tightened sufficiently to

prevent the removal of the nuts without the use of a wrench

Note 1 to entry: For pretensioned (3.5.16) and slip-resistant joints (3.5.19), it is additionally the tightness of a bolt

achieved by a few impacts of an impact wrench or by the full effort of a person using a standard podger spanner

(3.5.37).

3.5.19

slip-resistant joint

slip-critical joint

friction-type joint

friction-grip joint

connection (3.5.14) using high-strength bolts (3.5.1) tightened to induce a specified minimum bolt

pretension so that the resultant clamping action transfers the design shear forces acting in the plane of

the common contact surfaces by the friction developed between the contact surfaces

3.5.20

faying surface

plane of contact between two plies of a bolted joint

3.5.21

uncoated faying surface

faying surface (3.5.20) that has neither been primed, painted, nor galvanized and is free of loose scale,

dirt and other foreign material

3.5.22

coated faying surface

faying surface (3.5.20) that has been primed, primed and painted or protected against corrosion, except

by hot-dip galvanizing

3.5.23

galvanized faying surface

faying surface (3.5.20) that has been hot-dip galvanized

3.5.24

friction surface

faying surface (3.5.20) that provides a specific slip resistance in a slip-resistant joint (3.5.19)

3.5.25

slip factor

ratio of the frictional shear load at the faying surface (3.5.20) to the total normal force when slip occurs

3.5.26

firm contact

condition that exists on a faying surface (3.5.20) when the plies are solidly seated against each other,

but not necessarily in continuous contact

3.5.27

packing

filler plate

plate used to build up the thickness of one component

3.5.28

grip

plies of a joint through which the bolt passes, exclusive of washers or direct-tension indicators

3.5.29

protected storage

continuous protection of structural bolting components in closed containers in a protected shelter

3.5.30

pretensioning

DEPRECATED: preloading

installing and applying a specified pretension in a bolt

Note 1 to entry: Methods for pretensioning are provided in ISO 17607-6.

3.5.31

bolt tension measurement device

calibrated tension-indicating device that is used to verify the acceptability of the pretensioning (3.5.30)

method when a pretensioned joint (3.5.16) or slip-critical joint (3.5.19) is specified

3.5.32

torque method

method of pretensioning (3.5.30) that relies upon the application of a specific torque to the designated

part of the bolting assembly (3.5.4)

3.5.33

combined method

method of pretensioning (3.5.30) that relies upon the application of a specific torque to the designated

part of the bolting assembly (3.5.4), followed by the application of a specific relative rotation between

bolt and nut

3.5.34

spline-drive twist-off method

method of pretensioning (3.5.30) that relies upon the application of a torque to the nut that causes, from

the torsional shear applied to the spline by the wrench, the removal of the spline from the end of the

bolt

3.5.35

direct tension indicator method

method of pretensioning (3.5.30) that relies upon specific deformation of the protrusions of the direct

tension indicator

3.5.36

turn-of-nut method

method of pretensioning (3.5.30) that relies upon application of a specific relative rotation between bolt

and nut, starting from the snug-tight condition (3.5.18)

3.5.37

podger spanner

spud wrench

hand tool for aligning bolt holes and tightening bolts using the manual effort of the installer

3.5.38

twist-off shear wrench

electric or manual tool equipped with two co-axial sockets which react by torque one against the other,

the outer socket which engages the nut rotating clockwise, the inner socket which engages the spline-

end of the bolt (i.e. bi-hexagonal) rotating anticlockwise

3.5.39

routine observation

periodic monitoring of the work in progress

4 Execution specification and quality requirements

4.1 Execution specification

4.1.1 General

The specifier shall develop and maintain an execution specification for the structural steelwork.

National standards and documents that provide technically equivalent conditions may be used, in

whole or in part, in place of referenced ISO standards or requirements of this document. In these cases,

the technically equivalent national standards and documents, and deviations from the requirements of

this document, shall be referenced in the execution specification.

The necessary information and technical requirements for execution of each part of the structural

steelwork shall be agreed and completed before commencement of execution of that part of the

structural steelwork.

The execution specification shall include the following items as relevant:

a) additional information, see A.1;

b) options, see A.2;

c) execution levels, see 4.1.2;

d) identification and traceability requirements, see 4.1.3;

e) geometrical tolerances, see 4.1.4;

f) requirements for architecturally exposed structural steel (AESS), see 4.1.5;

g) requirement for a quality plan, see 4.2.3;

h) inspection, testing and corrections to be undertaken, see 6.1;

i) requirements specified on behalf of the purchaser/client.

Other items may be included in the execution specification, e.g. which components are designated as

main components.

There shall be procedures for making alterations to a previously agreed execution specification.

Guidance on the development of the execution specification is given in Annex B.

4.1.2 Execution levels

Four execution levels, denoted EXL1 to EXL4, are given, for which the required strictness increases

from EXL1 to EXL4. A description of the requirements is given in Table 1.

Execution levels for fabrication and erection shall be included in the execution specification.

Execution levels may apply to the whole structure or to a part of the structure or to specific details. A

structure can include several execution levels. A detail or group of details will normally be ascribed one

execution level. However, the choice of an execution level does not necessarily have to be the same for

all requirements.

The list of quality requirements related to execution levels is given in A.3.

Recommendations concerning the choice of execution levels are given in Annex C.

4.1.3 Identification and traceability

4.1.3.1 Identification

The requirements for identification shall be specified in the execution specification.

For identification requirements for steels, castings, high-strength cables, and structural bearings, see

ISO 17607-2.

For identification requirements for fabrication and for expansion joints for bridges, see ISO 17607-3.

For identification requirements for erection, see ISO 17607-4.

For identification requirements for welding consumables, shielding gases, and studs, see ISO 17607-5.

For identification requirements for bolting products and assemblies, see ISO 17607-6.

Identification documents shall be retained for all constituent products. The retention period shall be

specified in the execution specification.

For marking using steel stamps, see ISO 17607-3.

4.1.3.2 Traceability

The level of traceability shall be as required in Table 1 unless otherwise specified in the execution

specification. If required, the execution specification shall also identify and specify additional

traceability requirements for processes, procedures, operators, welders, machines, constituent

products, inspection records, or other factors in addition to those specified.

Table 1 — Traceability requirements

Execution Traceability

Requirement

level level

Traceability to the inspection documents for steel products is not

EXL1 T1

required.

Lot traceability to the inspection documents for steel products shall

EXL2 T2

be performed for main components.

Lot traceability to the inspection documents for steel products shall

EXL3 T3 be performed for main components and for steel sub-component

connections between main components.

Lot traceability to the inspection documents for all constituent

EXL4 T4

products is required.

4.1.4 Geometrical tolerances

The selection or designation of geometrical tolerances shall consider requirements for structural

stability for individual elements and for the structural system as a whole.

Geometrical tolerances for fabrication and erection shall be included in the execution specification.

Geometrical tolerances for fabrication are addressed in ISO 17607-3. Geometrical tolerances for

erection are addressed in ISO 17607-4.

NOTE Tolerances for constituent products are addressed in their applicable product standards.

4.1.5 Architecturally exposed structural steel (AESS)

If the structural steelwork includes items that are designated as architecturally exposed, the location

and requirements shall be included in the execution specification.

Natio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...