ISO 26022:2010

(Main)Road vehicles — Ergonomic aspects of transport information and control systems — Simulated lane change test to assess in-vehicle secondary task demand

Road vehicles — Ergonomic aspects of transport information and control systems — Simulated lane change test to assess in-vehicle secondary task demand

ISO 26022:2010 describes a dynamic dual-task method that quantitatively measures human performance degradation on a primary driving-like task while a secondary task is being performed. The result is an estimate of secondary task demand. The method is laboratory based, and ISO 26022:2010 defines the method, the minimum requirements for equipment to support the method, and procedures for collecting and analyzing data derived from the method. The method is applicable to all types of interactions with in-vehicle information, communication, entertainment and control systems; manual, visual, haptic and auditory, and combinations thereof. Secondary tasks requiring speed variations to be performed cannot be tested with this method. It applies to both Original Equipment Manufacturer (OEM) and aftermarket in-vehicle systems. It also applies to systems either portable or integrated into the vehicle. The driver behaviour principles, the specific task procedures and driving task correspond only to the operation of a passenger car.

Véhicules routiers — Aspects ergonomiques des systèmes de commande et d'information du transport — Essai du changement de voie simulé pour évaluer la demande de tâche secondaire à bord du véhiculex

General Information

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 26022

First edition

2010-09-01

Road vehicles — Ergonomic aspects of

transport information and control

systems — Simulated lane change test to

assess in-vehicle secondary task demand

Véhicules routiers — Aspects ergonomiques des systèmes de

commande et d'information du transport — Essai du changement de

voie simulé pour évaluer la demande de tâche secondaire à bord du

véhicule

Reference number

©

ISO 2010

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2010

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2010 – All rights reserved

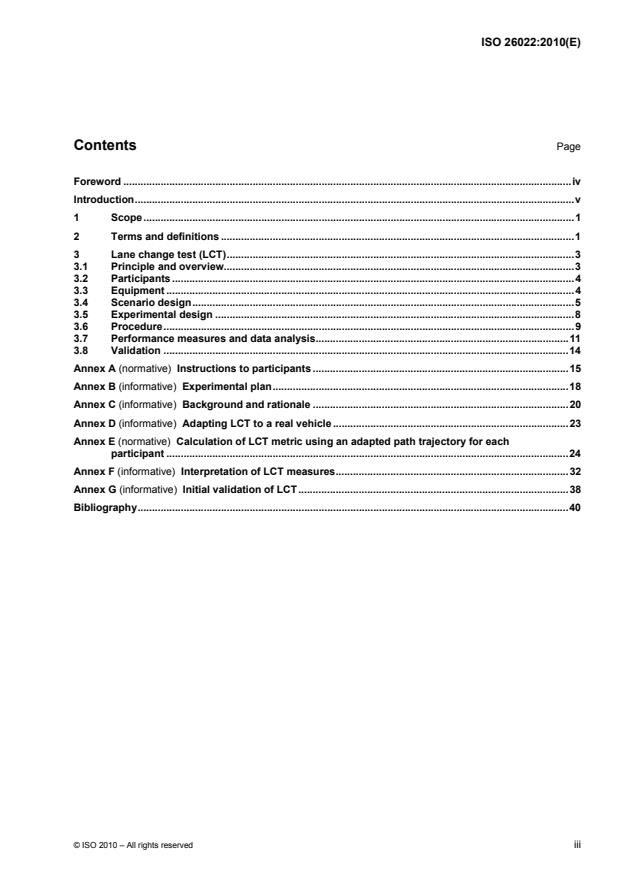

Contents Page

Foreword .iv

Introduction.v

1 Scope.1

2 Terms and definitions .1

3 Lane change test (LCT).3

3.1 Principle and overview.3

3.2 Participants .4

3.3 Equipment .4

3.4 Scenario design.5

3.5 Experimental design .8

3.6 Procedure.9

3.7 Performance measures and data analysis.11

3.8 Validation .14

Annex A (normative) Instructions to participants .15

Annex B (informative) Experimental plan.18

Annex C (informative) Background and rationale .20

Annex D (informative) Adapting LCT to a real vehicle .23

Annex E (normative) Calculation of LCT metric using an adapted path trajectory for each

participant .24

Annex F (informative) Interpretation of LCT measures.32

Annex G (informative) Initial validation of LCT.38

Bibliography.40

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 26022 was prepared by Technical Committee ISO/TC 22, Road Vehicles, Subcommittee SC 13,

Ergonomics applicable to road vehicles.

iv © ISO 2010 – All rights reserved

Introduction

Many advances are being made in introducing a wide range of information, communication, entertainment and

driver assistance systems in motor vehicles. Navigation aids, emergency messaging systems and wireless

communication, including e-mail and internet access, are all possible. Since many of these features require

the driver's attention it is important to recognise that, on one hand, these systems provide information and

assistance but, on the other hand, have the potential to distract the driver as well.

The lane change test (LCT) described in this International Standard, is a dual-task method that is intended to

estimate secondary task demand on the driver resulting from the operation of an in-vehicle device in a

laboratory setting. The method is simple and inexpensive so that it can be used by vehicle manufacturers,

in-vehicle device manufacturers, and other organizations.

The driver behaviour and attentional demand principles embodied in the LCT only apply to the operation of a

typical passenger car, as the vehicle dynamics model, driver eye height, and lane change dimensions and

geometries are scaled for such vehicles.

The test procedure specified in this International Standard uses software to set up the LCT task on a

computer, and to calculate the primary task performance measures. Appropriate software is available from the

ISO Central Secretariat.

INTERNATIONAL STANDARD ISO 26022:2010(E)

Road vehicles — Ergonomic aspects of transport information

and control systems — Simulated lane change test to assess

in-vehicle secondary task demand

1 Scope

This International Standard describes a dynamic dual-task method that quantitatively measures human

performance degradation on a primary driving-like task while a secondary task is being performed. The result

is an estimate of secondary task demand.

The method is laboratory based, and this International Standard defines the method, the minimum

requirements for equipment to support the method, and procedures for collecting and analyzing data derived

from the method.

The method is applicable to all types of interactions with in-vehicle information, communication, entertainment

and control systems; manual, visual, haptic and auditory, and combinations thereof. Secondary tasks requiring

speed variations to be performed cannot be tested with this method. It applies to both Original Equipment

Manufacturer (OEM) and aftermarket in-vehicle systems. It also applies to systems either portable or

integrated into the vehicle. The driver behaviour principles, the specific task procedures and driving task

correspond only to the operation of a passenger car.

2 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

2.1

adaptive model

reference path trajectory adapted to each participant

2.2

baseline

test condition with the primary task only

2.3

basic model

nominal reference path trajectory is the same for all participants

2.4

calibration task

type of reference task used for the purpose of comparing different tests or test results between sites, or over

time at a given site

2.5

course

path along which the simulated vehicle actually travels

2.6

dual task

two tasks concurrently performed, primary task plus a secondary task

2.7

environment

physical surroundings in which data are captured

2.8

goal

system end state sought by the driver and which is meaningful in the context of a driver's use of an in-vehicle

system

EXAMPLE Obtaining guidance to a particular destination; magnification of a map display; or cancelling route

guidance.

2.9

integrated system

two or more in-vehicle devices, which provide information to, or receive output from, the driver of a motor

vehicle, whose input and/or output have been combined or harmonized

EXAMPLE 1 An in-vehicle entertainment system and route guidance system which use the same visual, manual and

auditory interface.

EXAMPLE 2 An in-vehicle entertainment system whose auditory output mutes when a mobile phone call is made or

received.

2.10

lane change

lateral displacement of a vehicle from current lane to another lane, including crossing one or two lanes

2.11

lane change task

series of prescribed lane change manoeuvres that are the main component of the primary task in the lane

change test

2.12

outlier

an observation that lies outside the overall pattern of a distribution

2.13

manufacturer

organisation or person designing, developing, producing, integrating and/or supplying in-vehicle equipment

2.14

path deviation measure

mdev

difference between a reference path trajectory and an actual driven course

2.15

portable system

nomadic device

device which provides information to, or receives output from the driver of a motor vehicle, that can be used

within the vehicle without installation or can be rapidly and easily installed in and removed from the vehicle

2.16

primary task

course following and manoeuvring control activity which a participant performs throughout the duration of a

test (simulated substitute for driving)

2.17

reference task

a standardized secondary task which can be used to compare different levels of performance degradation

2 © ISO 2010 – All rights reserved

2.18

run

driving used to collect LCT data, typically consisting of 18 lane changes accomplished over a 3 minute period

in either single task or dual task conditions

2.19

secondary task

interaction with an in-vehicle information, communication, entertainment, or control system, carried out

concurrently with the primary task

2.20

secondary task demand

sum of perceptual, cognitive and motoric activity required by a secondary task

2.21

single task

one task (primary or secondary task) without additional activity (as opposed to dual task)

2.22

task

process of achieving a specific and measurable goal using a prescribed method

NOTE Ultimately, it is for the users of this International Standard to determine tasks that are meaningful in the

context of a driver's use of an in-vehicle device.

EXAMPLE 1 Obtaining guidance by entering a street address using the scrolling list method, continuing until route

guidance is initiated (visual-manual task).

EXAMPLE 2 Determining where to turn based on a turn-by-turn guidance screen (visual task).

2.23

track

three-lane, straight, simulated roadway

2.24

trial

investigation of one participant undertaking one repetition of one secondary task

3 Lane change test (LCT)

3.1 Principle and overview

The lane change test (LCT) is a simple laboratory dynamic dual task method that quantitatively measures

performance degradation in a primary driving task while a secondary task is being performed. The primary

task in the LCT is a simulated driving task which resembles the visual, cognitive and motor demands of

driving.

In the LCT, a test participant is required to do a primary task consisting of driving at a constant, system-limited

speed of 60 km/h along a simulated straight three-lane road containing a series of lane changes defined by

signs displayed on a screen. Simulated vehicle position is controlled by means of a steering wheel.

Participants are instructed in which of the lanes to drive by signs that appear at approximately regular intervals

on both sides of the track. The LCT is performed by participants according to pre-test instructions contained in

this International Standard (see Annex A). The method may be implemented in a laboratory, in a driving

simulator, in a mock-up or in a real vehicle.

There is no limitation to the definition of a secondary task according to this International Standard as long as

the secondary task is compatible with the LCT procedure.

EXAMPLE Secondary tasks requiring speed variations to be performed are not accommodated.

3.1.1 Application of the LCT

In a typical application of the LCT, the primary task performance degradation resulting from a certain

secondary task can be compared to the performance degradation resulting from a reference task

(see Annex B). A reference task is a standardized secondary task which can be used to compare different

levels of performance degradation. Such standardized reference task can also be employed to compare

different test sites or to verify consistency in repeated testing.

For product development purposes, the LCT can also be used to compare alternative HMI candidates or

solutions rather than comparing each of these solutions to a reference task (see Annex C).

3.2 Participants

Participants shall be licensed drivers having a similar level of familiarity with the secondary task under

investigation. Other relevant characteristics of the participants shall be recorded (gender, age, driving

experience and previous experience with the LCT). At least 16 participants shall take part in the evaluation of

a single secondary task or in the comparison of two or more secondary tasks for a within-subject design.

3.3 Equipment

3.3.1 Display of visual driving scene

The LCT visual driving scene shall be realised with a monitor or projector with a net refresh rate of at least

50 Hz. A minimum resolution of 1024 × 768 pixels with a colour depth of 24 bit (also called True Color) is

required. The size of the display device must meet the requirements defined in 3.4.3.

3.3.2 Testing environment

The illumination level in the testing environment shall be appropriate to the secondary task. Simulated engine

sound is optional and, if used, shall be adjusted to a low level.

Participants shall be comfortably seated directly in front of the primary task visual display while performing

each test. The seat shall not swivel or rock. A seat belt shall be used if it is assumed that the use of a seat belt

might influence the test results (e.g. restrictions in posture and reach).

3.3.3 Steering wheel and simulation characteristics

For the lateral control of the simulated vehicle, a computer game steering wheel can be used for a

laboratory/monitor setup. For seating buck or real vehicle testing, movement of the steering wheel shall

provide signals to replicate movements of the game steering wheel. The steering wheel force displacement

characteristics shall be approximately linear, and the tangential force at the rim to turn the steering wheel shall

be no more than 20 N. A centering (breakout) force, which is optional, shall be no more than 12 N. Adapting

LCT to a real vehicle is discussed in Annex D.

The overall transport delay between an initial steering input and a visual display response shall be < 120 ms

(not including the simulated vehicle model delay).

The steering wheel sensor shall have a resolution less than 1,5 degrees.

With the steering wheel turned 90 degrees from the straight ahead position, the simulated vehicle shall, at a

constant speed of 60 km/h, complete a 360 degree turn in between 13 s and 17 s, corresponding to a turning

circle of 70 m to 90 m in diameter.

3.3.4 Vehicle dynamics

The simulated vehicle shall be programmed to respond approximately like a typical passenger car in terms of

its size and inertial properties. Yaw rate to steer angle characteristics shall be represented by a first order lag

4 © ISO 2010 – All rights reserved

with an equivalent time constant of approximately 0,15 s (±0,03 s), including vehicle mathematical model

response and other simulation transport delays (see 3.3.3).

3.3.5 Measurement recording

All vehicle parameters (i.e. position on track, steer angle, heading angle, heading (yaw) rate, etc.) are

recorded at a sampling rate of at least 10 Hz. Additional parameters and information such as a unique time

stamp, track number and markers for tasks (typically set manually by the experimenter) shall also be

recorded. The LCT simulation shall have a minimum update rate of 100 Hz. In addition, secondary task

performance shall be recorded (see 3.7.3). These data are needed to ensure the participant's compliance with

the instructions (see Annex A).

3.4 Scenario design

3.4.1 Simulated roadway and surroundings

The simulated roadway (see Figure 1) consists of a straight, three-lane track. A series of lane changes are

defined by roadside signs placed at approximately regular intervals. The road is located on a plain green field.

Figure 2 shows the dimensions of the lanes and the markers (delineators). The road surface is grey (like a

typical paved road). Lane markings are white.

The simulated roadway shall be displayed as if viewed from an eye point 120 cm ± 10 cm over the road

surface. This is consistent with that of a typical passenger car.

NOTE 1 The roadway and lane change geometries and the vehicle dynamics are not scaled to correspond to a truck or

other large commercial vehicle.

Minimum track length shall be 3 000 m corresponding to 3 min of driving at 60 km/h. This is sufficient in length

to collect 2 min of LCT data.

NOTE 2 According to the signs in Figure 1, the participant has to change from the current (middle lane) to the right

lane.

Figure 1 — Simulated roadway

Dimensions in metres

3,85

0,14

3,85

1,50

3,85

11,20

Key

1 road edge line

Figure 2 — Dimensions of the road markers (not to scale)

3.4.2 Signs

Both “START” signs and “Lane Change” signs appear in pairs on both sides of the simulated roadway

(see Figure 1 for example of sign positions). “Lane Change” signs are rectangular and have a thin black

border and black symbols on a white background (see Figure 4). The signs are 2,0 m wide and 1,0 m high

and the lower border is 1,0 m above the ground. The downwards arrow on the “Lane Change” sign indicates

the target lane. In Figure 4, (a), (b), and (c) show the left, middle and right lanes, respectively. Dimensions of

the “Start” sign can be the same as the “Lane Change” sign, but the colours shall be different from those of

the “Lane Change” signs (see Figure 3). The “START” sign shall appear approximately 150 m before the first

“Lane Change” sign.

Figure 3 — “Start” sign

Figure 4 — “Lane Change” signs

6 © ISO 2010 – All rights reserved

3.4.3 Experimental and measurement setup

3.4.3.1 Participant's view of display

The horizontal viewing angle to the display for the road scenery (monitor or screen) shall be between 20° and

55°. The eye-to-display distance shall be no less than 60 cm. The horizon of the visual scene shall be

between −5° and +5° from the participant's eye point height.

3.4.3.2 Steering wheel location

The steering wheel shall be located where it does not interfere with the visual scene of the LCT. It shall be

capable of being handled comfortably.

3.4.3.3 Standard scenario

The standard scenario for a 3 000 m test track is as follows:

⎯ only the scripted instructions are given to the participants (see Annex A),

⎯ speed is specified and limited to 60 km/h, resulting in a duration of about 180 s per track,

⎯ there are 18 pairs of “Lane Change” signs along a track.

3.4.3.4 Lane change sign spacing

The lane change signs are always visible but blank until the lane indications on the signs appear (i.e. pop-up)

at a distance of 40 m before the signs. The mean distance from sign to sign is 150 m (a minimum of 140 m

plus an exponentially distributed random variable with a mean of 10 m), so that the mean duration between

two lane changes is about 9 s (at a speed of 60 km/h).

3.4.3.5 Ordering the lane change directions

The number of the six possible lane changes (from left lane to middle lane, from left lane to right lane, etc.)

shall be balanced within 18 pairs of signs. This balancing also applies if tracks longer than 3 000 m are used.

If the total number of pairs of signs on a track is not a multiple of 18, balancing shall be done to the extent

possible. The presentation order of lane change signs in tracks used for different runs shall be randomised to

avoid learning effects. At least five different orders shall be used randomly for different runs.

3.4.3.6 Secondary task equipment

The equipment for evaluating the secondary task shall be positioned where the participants can properly

interact with it. The position depends on the purpose of the test, e.g. systems intended for vehicle use shall be

positioned in their intended locations in the vehicle relative to the participant.

3.4.3.7 Document the setup

Because experimental setting effect may have an impact on the results, description of the setup, viewing

distance and angle to road scene and type of road scene presentation, testing environment (personal

computer, buck or complete car), and type of seat shall be reported.

It has been shown that better lane change trajectories have resulted when using a driving simulator instead of

a personal computer [12], presumably due to the increased visual realism in a driving simulator. This

emphasises the need to describe precisely each equipment setup before comparing the results of different

experimental contexts.

3.5 Experimental design

3.5.1 General

A within-subject design shall be used (see Clause B.1). This allows for each participant to experience both the

single and dual task conditions and facilitates statistical comparison between the two conditions. Furthermore,

the experimental design shall be designed to minimize carry over or training effects between the two

conditions (for an example see Figure 5).

The secondary task(s) is (are) conducted in the dual task runs. The secondary task can either be performed

block wise (the same secondary task repeated within one track is a blocked run) or in a mixed design

(different secondary tasks given within one track is a mixed run). See Annex B.2 for rationale. Dual task runs

[primary task plus secondary task(s)] are conducted between baseline runs.

Each participant performs identical secondary tasks of equal difficulty but with different presentation order.

The order of secondary tasks, the track parts used and the combinations between secondary task and track

parts used shall be counterbalanced or randomised.

Start and end points of each secondary task operation are recorded, as well as driving performance during

single and dual task conditions for later data analysis. Start point is typically as soon as the verbal instructions

have been given. End point is the last operation made by the participant on the secondary task (e.g. a button

press) which leads to a predefined final state.

Total time on task for each secondary task shall be no less than 2 min. This means that at least 12 lane

changes during which the secondary task is being performed shall be taken into account.

During the LCT in dual task conditions, the experimenter shall monitor participant behaviour to ensure that the

participant is following the instructions and engaging in both tasks as instructed.

If the participant does not follow the experimental instructions (as described in Annex A) this part of the data

shall be excluded from data analysis. Furthermore, if the participant does not perform the secondary task, this

shall be recorded and considered in the evaluation of the interface design.

3.5.2 Baseline runs

In the experimental design, and once training is completed, baseline run data are collected at the beginning, in

the middle and at the end of the experimental phases. If only 2 baseline runs are carried out to avoid overly

long experimentation time, these runs shall be at the beginning and at the end of the experimental phases.

Mean deviation values (mdev) in the baseline runs can later be compared to check for learning effects. The

participant is free to use both hands for steering. One track with 18 signs (about 3 min) shall be used for each

baseline run.

A participant shall accomplish at least one baseline run at the beginning of the experimental phase without a

lane change error (wrong lane or missed lane change). This will ensure an adequate level of skill and training

(see Annex A). It will also provide at least one baseline suitable for calculating the participant's adaptive model

(see Annex E). To establish baseline performance for comparison with dual task performance, the mdev

values from several error-free baseline runs can be averaged.

3.5.3 Blocked runs

Given a blocked design, either the same secondary task with different parameters or a new task of the same

type is repeated within a single run for a duration of at least 2 min (see Figure 5).

With a blocked design a driving distance of 3 km (corresponding to 3 min) should be sufficient to collect data

for at least 2 min, with time for instructions for each secondary task item considered.

8 © ISO 2010 – All rights reserved

3.5.3.1 Mixed runs

In a mixed design, different secondary tasks (ST) are repeated within a single run (see Figure 5). With a

mixed design, each secondary task shall be repeated enough times to record 2 min of data for each

secondary task. This will require more than one run if there is more than one secondary task.

For analysis, the combination of all of the results of a given secondary task are used to calculate a single

mean deviation.

3.6 Procedure

3.6.1 Participant instructions and training

All participants shall receive identical instructions. These shall be read to the participant. As described in

Annex A, the participant shall receive:

⎯ information on the general purpose of the test, and in particular instructions on the lane change task,

⎯ training on the primary task only,

⎯ training on the secondary tasks only,

⎯ training on the dual task situations,

⎯ instructions before first baseline run,

⎯ instructions before dual task testing, and

⎯ if required, instructions during dual task testing.

Baseline run (3)

Baseline run (3)

Dual Task Run 4 Dual Task Run 4

ST#4, ST#4, ST#4, . ST#1, ST#3, ST#4, .

Instruction ST#4

Dual Task Run 3

ST#2, ST#4, ST#2, .

Dual Task Run 3

ST#3, ST#3, ST#3, .

Baseline run (2)

Instruction ST#3

Dual Task Run 2

Baseline run (2)

ST#3, ST#1, ST#2, .

Dual Task Run 1

Dual Task Run 2

ST#4, ST#1, ST#3, .

ST#2, ST#2, ST#2, .

Instruction ST#2

Baseline run (1)

Dual Task Run 1

ST#1, ST#1, ST#1, .

Instruction on ST#1

Instruction ST#1

Instruction on ST#2

Instruction on ST#3

Baseline run (1)

Instruction on ST#4

blocked mixed

design design

Figure 5 — Example of blocked and mixed experimental design

If a participant fails to meet the baseline criterion for minimum mdev (see Clause A.2) due to improper lane

positioning, the importance of staying in the middle of the lane between lane changes shall be emphasized.

Upon request, participants shall be instructed to perform the primary task and the secondary task as

described in Clause A.4.

3.6.2 Allocation of attention in dual task conditions

3.6.2.1 General

The interpretation of LCT performance measures depends upon the way that participants allocate attention

between the primary task and the secondary task they are performing at the same time. Because the lane

change test is a divided attention method, in order for the measures generated by the LCT (mdev) to be

consistently interpretable, an assumption is made that the participant is allocating attention in such a way that

if the secondary task demand increases, it will lead to degradations in primary task performance.

However, participants may allocate attention differently than this, even when carefully instructed. If they do, it

may lead to LCT results that obscure important differences between the secondary tasks in their demands on

participant attentional resources. For example, two tasks may produce similar mdev values, but differ

significantly in the number of errors made on each secondary task, the number of extra (unnecessary)

secondary task entries made on each task, or the number of secondary tasks completed during the run [10].

Information on the interpretation of LCT measures is given in Annex F.

There are at least three different ways in which a participant might allocate attention between the tasks during

an LCT.

3.6.2.2 More attention to the primary task

Participants might allocate attention so as to try to optimize their performance on the primary task, and let the

secondary task performance suffer when they become overloaded. It is possible, for example, that because

the demand associated with the lane changes is approximately periodic (rather than continuous), a participant

might use a strategy in which activity on the secondary task is suspended during the lane change, and

resumed when the lane change is completed. Such a strategy might lead to better mdev scores, but degrade

secondary task performance, by slowing it down, increasing errors (if task information is forgotten or there is

difficulty resuming it), or leading to extraneous control inputs or display search time.

3.6.2.3 More attention to the secondary task

Participants might allocate attention so as to maintain or optimize their performance on the secondary task

and let their performance on the primary task suffer. Under this attentional strategy, overload from dual task

demands would become apparent in mdev measures, while secondary task performance may not degrade

from that observed in a single task condition.

3.6.2.4 Attention to both primary task and secondary task

Participants are asked to manage both tasks concurrently according to the instructions in Annex A

(e.g. through frequent task-switching), with similar attentional allocations to both tasks. Under this attentional

allocation, degradations in performance would be expected to show up on both tasks when their combined

demands exceed a participant's momentary resource capacity. Therefore, both mdev measures and

secondary task performance measures would be expected to show degradation.

3.6.2.5 Interpretation of dual task results

Attentional allocation is not yet fully understood, and it is not clear that instructions or incentives will ensure

that the allocation of attention between tasks will be the same for all participants. The literature on dual-task

methods has demonstrated that results are best interpreted when measurements of both tasks performed

concurrently are obtained together with measurements of each of the tasks done in a single task condition.

10 © ISO 2010 – All rights reserved

3.6.3 Test procedure details

The main purpose of the lane change test is to compare performance degradations resulting from each of two

or more secondary tasks. One of the secondary tasks could typically be a reference task (see 3.1). The test

shall be performed as a “within-participant” procedure. This means that, for each participant, performance

shall be established and compared under dual task conditions for runs with the secondary task(s) under test,

and for runs with reference task(s) if appropriate.

The experimenter shall give the participant instructions on when to start the secondary task (see A.6). Start

and end point of operation of the secondary task shall be recorded. A secondary task starts immediately after

the experimenter's verbal instruction is finished, or when the participant starts performing the secondary task,

whichever event occurs first. If there is a delay between end of instructions and participant start of secondary

task, start of task shall be considered to be at end of instructions.

3.7 Performance measures and data analysis

3.7.1 Path deviation measures of secondary task demand

Two path deviation measures can be used to quantify the effect of secondary task demand on primary task

performance. These path deviation measures can be calculated using an adaptive model (adaptive mdev) or a

basic model (basic mdev). The adaptive model calculates a reference path trajectory (adapted curve) for a

baseline run for each participant. The adaptive model and method shall be used to quantify and compare task

demand for various dual task conditions. The basic model can also be used to compare a participant's path

performance to a nominal reference path trajectory that is the same for all participants. Use of the basic model

is optional.

These mean path deviation measures cover important aspects of the participant's performance. These include

detection (late detection of a sign or missing a sign), quality of the manoeuvre (slow lane change results in

larger deviation), and lane keeping quality, all of which may result in an increased deviation.

3.7.1.1 Adaptive model

The adaptive model shall be used to quantify the differences between experimental conditions. The effect of

secondary task demand is measured by the adaptive mdev which is the mean deviation between the actual

driving course of the participant along the track and the reference path trajectory from the adaptive model (see

Figure 6 for a symbolic example of the model path and actual driving data). This reference path is adjusted to

each participant in order to better match their actual driving behaviour in response to the signs in the baseline

task. The result of the adaptation calculation is that the start of the lane change, the lane change length, and

the overall lateral position in the lane (as shown by the solid line in Figure 6 and the solid red line in Figure 7)

are adjusted to match the baseline behaviour of the respective participant. The details of these adaptation

procedures and the calculation of the resulting adapted path trajectory are given in Annex E.

3.7.1.2 Basic model

The basic model is similar in concept and application to the adaptive model, except that the reference path

trajectory is nominal and the same for each participant (see Figure 8). The measure of the effect of

secondary-task demand is the basic mdev which is the mean deviation between this nominal basic path model

trajectory and the actual driving course of the participant along the track (see Figure 6). The nominal basic

path model trajectory is based on the sign geometry and spacing as described in 3.4.3.4. Once the instruction

content of the sign becomes visible (pops-up), a reaction time of 600 ms to initiate the lane change is

assumed. A participant would cover a distance of 10 m within this time (16,67 m/s × 0,6 s = 10 m). Therefore,

the basic model trajectory turns 30 m before a lane change sign to take reaction time into account. The basic

lane change has a length of 10 m regardless of whether it is a single or a double lane change, as shown in

Figure 8.

3.7.2 Performance calculation using the adaptive mean deviation value

The mean deviation (adaptive mdev) between the adaptive model path trajectory and the participant's actual

driving course shall be calculated as the performance parameter of main interest. Only the section(s) of the

track in which the participant is performing the respective secondary task shall be used for analysis, i.e. those

sections where the experimenter gave instructions are excluded from the analysis if such instructions last

more than 1 s.

To facilitate this, the relevant sections shall be marked by the experimenter during each run with appropriate

markers in the recordings. Trials with secondary tasks which were not completed (due to participants inability

or time limits), however, can be included in the analysis as long as the participant worked on the secondary

task to their best ability, as instructed.

NOTE According to the signs, the driver has to change from the middle to the right lane and then to the left lane.

Note that Figure 6 is not to scale (driving direction is from left to right). The average path deviation is the total area

between the reference path trajectory of the adaptive or basic model and the driving course (m ) divided by distance

driven (m).

Figure 6 — Comparison of reference path trajectory (solid line) and actual driving course (dotted line)

Key

1 sign content pop-up (40 m) 4 adapted right lane position

2 adapted left lane position 5 adapted start of lane change

3 adapted centre lane position 6 adapted lane change length

NOTE: Dashed line shows an incorrect lane change.

Figure 7 — Adaptive model trajectory parameters relative to sign content pop-up and sign position

12 © ISO 2010 – All rights reserved

Dimensions in metres

10 10 20

Key

1 sign content pop-up

Figure 8 — Basic model trajectory values relative to sign content pop-up and sign position

The mean deviation (mdev) between either the adaptive or basic model path trajectory and the actual driven

course can be calculated as follows:

⎡⎤

1 ⎛⎞yy−

ii+−11

x (1)

⎢⎥deviation,i⎜⎟

∑

S 2

⎝⎠

⎣⎦

xx=−x

deviation,iiposition, reference,i

where

x is the lateral deviation;

deviation,i

S is the length of the data segment analysed;

y is the longitudinal vehicle position along the track;

x is the actual vehicle lateral position on the track;

position,i

x is the lateral position of the reference (adaptive or basic) path trajectory.

reference,i

This calculation is done across all data segments which are relevant for a certain experimental condition. In

other words, the invalid data segments (e.g. time for instructions by experimenter) are removed and the

remaining valid data are handled as if they were one continuous set of data. The same applies to an

experimental design where secondary tasks of one experimental condition are distributed over several

experimental runs. In baseline runs mdev is calculated for the section between the start sign and 50 m after

the last of 18 lane change signs.

The resulting mdev values shall be calculated for each participant and each experimental condition of interest,

for example, for baseline driving, for dual task conditions with each secondary task under test, and with a

reference task.

3.7.3 Measures of secondary task performance

Because participants may allocate attention in multiple ways during the LCT, measurements of primary task

performance (adaptive mdev) and secondary task completion time, number of secondary task completions

and number of errors, shall be obtained. These secondary task measures are described in Clause F.1.2 and

their relevance will depend on the type of task.

3.7.4 Analyzing differences between dual task conditions

An evaluation is accomplished by comparing mdev values. This can involve comparing performance in two

different dual tasks, or comparing dual task performance with the baseline condition. The mdev differences

can be statistically analyzed (e.g. ANOVA, t-Test, Friedman Test, etc., depending on the specific design and

research question). All statistical parameters relevant to the comparison shall be reported (e.g. t-values,

F-values, p-values, degrees of freedom, sample size, and outliers). In data diagrams, error bars with standard

errors are recommended. The data should be examined for outliers because they can influence the

distribution of mean deviation. Any treatment of outliers shall be reported.

In general, while comparisons of mdev values (as discussed above) provide an overall measure of dual task

differences, mdev alone may not be sufficient to explain the differences between two secondary tasks with

similar mdev values, as discussed in Annex F. Similarly, not finding a statistically significant difference

between mdev values does not prove that the tasks are equivalent. Additional performance variables for the

primary task and the secondary task are discussed in Annex F and can be considered in order to provide a

more complete assessment of those tasks. These measures can also help to determine whether the main

performance degradations from resource overload are reflected in the primary task measure (mdev), or

whether some changes in dual task performance are reflected in secondary task measures.

3.8 Validation

Initial validation results are summarized in Annex G. Data are shown from a study comparing dual task

performance with eight secondary tasks of varying levels of difficulty, using both LCT and an over-the-road

vehicle. The results show a correlation between mdev in LCT and standard deviation of lane position over-the-

road. The results of driving simulator studies are also discussed. Additional validation studies should be

carried out, as experience is gained with the application of LCT.

14 © ISO 2010 – All rights reserved

Annex A

(normative)

Instructions to participants

A.1 Before training on the primary task

Outline for instructions to participants prior to primar

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...