ISO/IEC 8441-1:1991

(Main)Information technology — High density digital recording (HDDR) — Part 1: Unrecorded magnetic tape for (HDDR) applications

Information technology — High density digital recording (HDDR) — Part 1: Unrecorded magnetic tape for (HDDR) applications

This part of ISO/IEC 8441 specifies requirements for unrecorded magnetic tape designed for high density digital recording (HDDR) having the following characteristics: a) nominal thickness 25,4 urn (0,001 in); b) longitudinal magnetic orientation; c) coercivity 72 kA/m (900 Oe) max. These tapes are suitable for interchange in accordance with ISO/IEC 8441-2. Requirements for packaging are also included. NOTE 1 Tapes of coercivity above 32 kA/m (400 Oe) are usually classified as high energy tapes and users should establish compatibility with equipment used for driving them. Annex A gives guidance on glass and metal-flanged reels. Annex B gives information on the wear of recording heads. Different categories of environmental conditions and their effects on tape are dealt with in annex C. Severe operating conditions are considered in annex D. Surface electrical resistance testing is dealt with in annex E. A tape abrasivity testing technique is described in annex F. A list of bibliographical references is given in annex G. NOTES 2 It is recognized that archival interchange tapes, or those produced by systems in use prior to the publication of this part of ISO/lEC 8441, may not comply with the requirements and/or recommendations herein. 3 Various tests and procedures herein refer to recording with a.c. HF bias. In practice, certain HDDR systems do not use bias. The use of bias in this part of ISO/IEC 8441 does not imply that the tape so tested is in any way unsuitable for a biasless system.

Technologies de l'information — Enregistrement numérique à haute densité (HDDR) — Partie 1: Bande magnétique vierge pour les applications HDDR

General Information

Standards Content (Sample)

INTERNATIONAL

STANDARD 84414

First edition

1991-05-15

Information technology - High density digital

recording (HDDR) -

Part 1:

Unrecorded magnetic tape for (HDDR)

applications

Technologies de i’informa tion - Enregistrement numkrique 5 haute

densite (HDDR) -

Partie 1: Bande magnetique vierge pour les applications HDDR

--

---

--

--

= Z

--

-

-z

=

= =

=

z

;

I

- -

L

z

g

= Reference number

E

=

z

Z

z

G?T G

--____I_ ISO/IEC 8441-1:1991(E)

~__-----

ISOAEC 8441=1:1991(E)

Contents

Paqe

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .*.

1 Scope .

.................................. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Normative references

................................. 1

3 Definitions

... ..............................

4 General . . .

4.1 Materials . .

.....................................................................................

4.2 Tape reels

4.3 Tape wind . .

4.4 Packaging .

rj

5 Test conditions .

5.1 General . .

..................................................................................

5.2 Conditioning

.............................................. ............................

5.3 Test environment

6 Dimensions .

........ 3

6.1 Tape width . .

6.2 Tape length .

..............................................................................

6.3 Tape thickness

.........................................................................

7 Physical properties

7.1 Yield strength . .

7.2 Elongation under stress .

....................................................................................

8 Performance

8.1 Reference test system .

......................................................................................

8.2 Sensitivity

............................ 5

8.3 Wavelength response .

............................................ 6

8.4 Output level uniformity (long term)

....................................

8.5 Instantaneous nonuniformity (dropouts)

0 ISO/lEC 1991

All rights reserved. No part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, Including photocopylng and microfilm, without

permission in writing from the publisher.

lSO/lEC Copyright Office l Case Postale 56 l CH-1211 Genkve 20 l Switzerland

Printed in Switzerland

ii

EC 8441=1:1991(E)

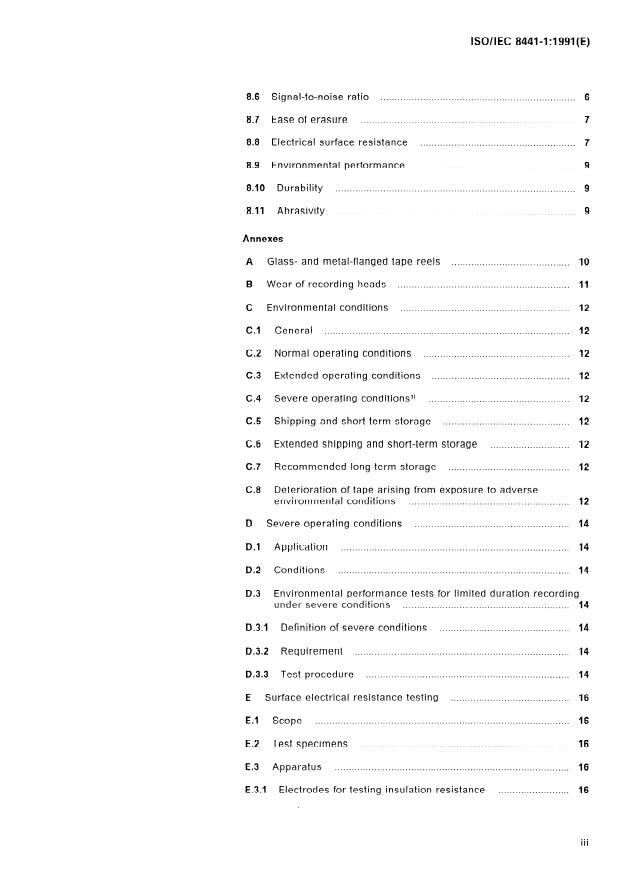

..s.............*........... 6

8.6 Signal-to-noise ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

............................................. ............................... 8

8.7 Ease of erasure

....... ................................ ................ 7

8.8 Electrical surface resistance

........................................................ 9

8.9 Environmental performance

8.10 Durability . 9

Abrasivity .

8.11

Annexes

.......... IO

A Glass- and metal-flanged tape reels .

B Wear of recording heads .

C Environmental conditions . . .

Cl General .

......... 12

C.2 Normal operating conditions .

................................................. 12

C.3 Extended operating conditions

.................................................. 12

C.4 Severe operating conditions3)

C.5 Shipping and short-term storage . . 12

............................ 12

C.6 Extended shipping and short-term storage

C.7 Recommended long-term storage .

C.8 Deterioration of tape arising from exposure to adverse

......................................................... 12

environmental conditions

..................... .................................. 14

D Severe operating conditions

D.1 Application .

......... .................................................................... ..... 14

0.2 Conditions

0.3 Environmental performance tests for limited duration recording

under severe conditions . . 14

.............................................. 14

0.3.1 Definition of severe conditions

0.3.2 Requirement .

........................................................................ 14

D,3,3 Test procedure

E Surface electrical resistance testing .

........................................ 16

E.1 Scope .

......................................... .............. 16

E.2 Test specimens .

E.3 Apparatus .

E.3.1 Electrodes for testing insulation resistance .

.

. . .

III

ISO/IEC 8441=1:1991(E)

........ 16

E.3.2 Electrodes for testing volume and surface resistance

E.3.3 Electrode materials .

potential . 16

E.3.4 Direct-current

E.3.5 Measuring equipment . 17

.............................. 17

E.3.6 Switches and keys .

................................... 17

E.4 Procedure .

..................................................... 17

E.4.1 Conditioning of specimens

..................................... 17

E-4.2 Precautions in mounting specimens

resistance . 17

E.4.3 Method of measuring

...................................... 19

E.4.4 Insulation resistance determination

.................... 19

E.4.5 Volume and surface resistance determination

.......................................... 20

E.4.6 Surface resistance determination

................................ 21

E.5 Report .

.................................... 26

F Tape abrasivity testing .

..................... 26

F.1 Scope .

...................................................................................... 26

F.2 Principle

Apparatus .

F.3

Sensor . .

F.3.1

F.3.2 Dummy head assembly . .

F.3.3 Tape abrasivity meters) .

F.3.4 Reference tapes) .

........................... 26

F.4 Procedure .

........................................................ 26

F.4.1 Cleaning and measuring

........................................ 27

F.4.2 Requirement . .

.......................... 28

G Bibliography .

iv

ISO/IEC 8441=1:1991(E)

Foreword

IS0 (the International Organization for Standardization) and IEC (the

International Electrotechnical Commission) form the specialized system

for worldwide standardization. National bodies that are members of IS0

or IEC participate in the development of International Standards through

technical committees established by the respective organization to deal

with particular fields of technical activity. IS0 and IEC technical com-

mittees collaborate in fields of mutual interest. Other international or-

ganizations, governmental and non-governmental, in liaison with IS0

and IEC, also take part in the work.

In the field of information technology, IS0 and IEC have established a

joint technical committee, ISO/IEC JTC 1. Draft International Standards

adopted by the joint technical committee are circulated to national bod-

ies for voting. Publication as an International Standard requires ap-

proval by at least 75 % of the national bodies casting a vote.

International Standard lSO/IEC 8441-1 was prepared by Joint Technical

Committee ISO/IEC JTC 1, Wormafion technology.

ISO/IEC 8441 consists of the following parts, under the general title In-

formation technology - High density digital recording (HDDR):

- Part 1: Unrecorded magnetic tape for (HDDR) applications

c

- Part 2: Guide for interchange practice

Annexes A, B, C, D, E, F and G of this part of ISO/IEC 8441 are for infor-

mation only.

Introduction

This part of ISOAEC 8441 gives guidance on the performance levels of

unrecorded tape suitable for high density digital recording for inter- 5

change purposes. It should be noted that the performance levels speci-

fied may differ from those attained at the time of purchase of the tape.

ISOllEC 8441-1:1991(E)

INTERNATIONAL STANDARD

Information technology - High density digital recording

(HDDR) -

Part 1:

Unrecorded magnetic tape for (HDDR) applications

3 Various tests and procedures herein refer to recording

1 Scope

with a.c. HF bias. In practice, certain HDDR systems do

not use bias. The use of bias in this part of ISO/IEC 8441

does not imply that the tape so tested is in any way un-

suitable for a biasless system.

This part of ISO/IEC 8441 specifies requirements for

unrecorded magnetic tape designed for high density

digital recording (HDDR) having the following

2 Normative references

characteristics:

The following standards contain provisions which,

a) nominal thickness 25,4 urn (0,001 in);

through reference in this text, constitute provisions

of this part of ISO/IEC 8441. At the time of publica-

b) longitudinal magnetic orientation;

tion, the editions indicated were valid. All standards

are subject to revision, and parties to agreements

c) coercivity 72 kA/m (900 Oe) max.

based on this part of ISO/IEC 8441 are encouraged

to investigate the possibility of applying the most

These tapes are suitable for interchange in accord-

recent editions of the standards indicated below.

ance with ISO/IEC 8441-2.

Members of IEC and IS0 maintain registers of cur-

rently valid International Standards.

Requirements for packaging are also included.

IS0 1184:1983, Plastics - Determination of tensile

NOTE 1 Tapes of coercivity above 32 kA/m (400 Oe) are

properties of films.

usually classified as high energy tapes and users should

establish compatibility with equipment used for driving

them.

IS0 1860:1986, Information processing - Precision

reels for magnetic tape used in interchange instru-

Annex A gives guidance on glass and metal-flanged

mentation applications.

reels. Annex B gives information on the wear of re-

cording heads. Different categories of environmental

conditions and their effects on tape are dealt with in

annex C. Severe operating conditions are con- 3 Definitions

sidered in annex D. Surface electrical resistance

testing is dealt with in annex E. A tape abrasivity

For the purpose of this part of ISO/IEC 8441, the fol-

testing technique is described in annex F. A list of

lowing definitions apply.

bibliographical references is given in annex G.

NOTE 4 Tape speed is taken to be 3048 m/s (120 in/s),

NOTES

unless otherwise stated.

2 It is recognized that archival interchange tapes, or

3.1 abrasivity: The propensity of a magnetic tape to

those produced by systems in use prior to the publication

cause wear of a recording head, by the passage of

of this part of ISO/lEC 8441, may not comply with the re-

quirements and/or recommendations herein. the tape over the head.

ISOAEC 844%1:1991 (E)

NOTES duration, in microseconds, for a tape speed of 3048 m/s

(120 in/s) (for a general definition, see ISO/IEC 8441-2).

5 It may be expressed as micrometres of head wear per

metre of tape passed (microinches per inch), or as a value

3.8 operating bias current: That bias current

relative to a given reference tape.

through the recording head which gives a 2 dB fall-

off (overbias peak) of the peak output from the ref-

6 The actual wear produced in the recording head will

erence tape when a 2,0 MHz signal is recorded at

also depend on the tape speed and tension (see

reference level (see 3.13), at a tape speed of

annex B).

3048 m/s (120 in/s).

3.2 durability: The ability of a tape to maintain its

3.9 output level uniformity (long term): The differ-

output uniformity and dropout characteristics after

ence between the maximum and minimum peak

a given number of passes on the reference test re-

output levels, the peak value in either case being the

corder.

value that contains 95 % of the peaks (see figure 1

and 8.4).

3.3 ease of erasure: The ability of a specified eras-

ing field to effect a specified reduction in the level

of a signal recorded on a tape.

95 % probability band Envelope of peak amplitudes

r /

3.4 ele

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.