ISO/IEC 23651:2003

(Main)Information technology — 8 mm wide magnetic tape cartridge for information interchange — Helical scan recording — AIT-3 format

Information technology — 8 mm wide magnetic tape cartridge for information interchange — Helical scan recording — AIT-3 format

ISO/IEC 23651:2003 specifies the physical and magnetic characteristics of an 8 mm wide magnetic tape cartridge containing a memory chip to enable physical interchange of such cartridges between drives. It also specifies the quality of the recorded signals, the recording method and the recorded format - called Advanced Intelligent Tape No. 3 (AIT-3 format) - thereby allowing data interchange between drives by means of such magnetic tape cartridges. ISO/IEC 23651:2003 specifies two types of cartridge depending on the thickness of the magnetic tape contained in the case. Information interchange between systems also requires, at a minimum, agreement between the interchange parties upon the interchange code(s) and the specifications of the structure and labelling of the information on the interchanged cartridge.

Technologies de l'information — Cartouche de bande magnétique de 8 mm de large pour échange d'informations — Enregistrement par balayage en spirale — Format AIT-3

General Information

Standards Content (Sample)

INTERNATIONAL ISO/IEC

STANDARD 23651

First edition

2003-08-01

Information technology — 8 mm wide

magnetic tape cartridge for information

interchange — Helical scan recording —

AIT-3 format

Technologies de l'information — Cartouche de bande magnétique de

8 mm de large pour échange d'informations — Enregistrement par

balayage en spirale — Format AIT-3

Reference number

©

ISO/IEC 2003

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO/IEC 2003

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO/IEC 2003 – All rights reserved

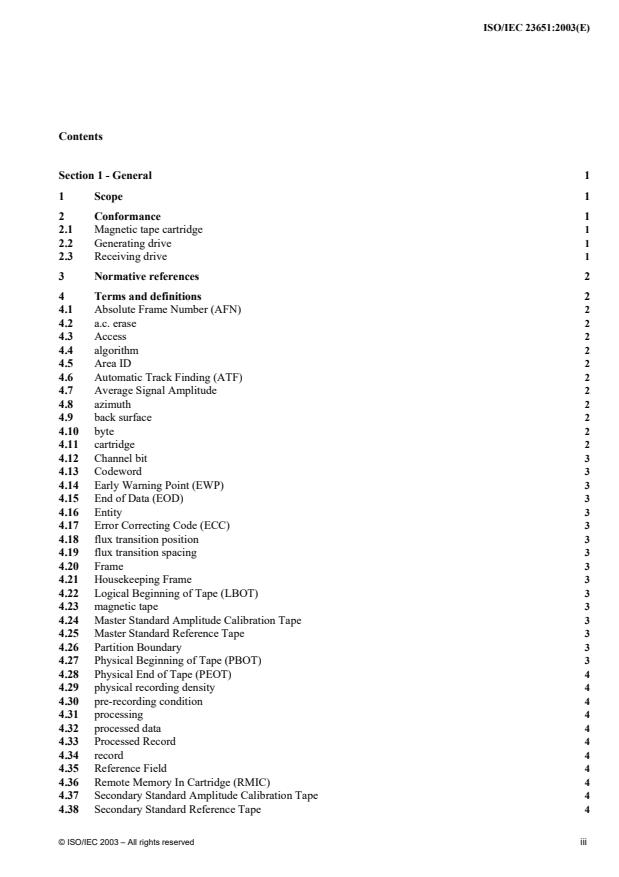

Contents

Section 1 - Genera l 1

1Scope 1

2 Conformance 1

2.1 Magnetic tape cartridge 1

2.2 Generating drive 1

2.3 Receiving drive 1

3 Normative references 2

4 Terms and definitions 2

4.1 Absolute Frame Number (AFN) 2

4.2 a.c. erase 2

4.3 Access 2

4.4 algorithm 2

4.5 Area ID 2

4.6 Automatic Track Finding (ATF) 2

4.7 Average Signal Amplitude 2

4.8 azimuth 2

4.9 back surface 2

4.10 byte 2

4.11 cartridge 2

4.12 Channel bit 3

4.13 Codeword 3

4.14 Early Warning Point (EWP) 3

4.15 End of Data (EOD) 3

4.16 Entity 3

4.17 Error Correcting Code (ECC) 3

4.18 flux transition position 3

4.19 flux transition spacing 3

4.20 Frame 3

4.21 Housekeeping Frame 3

4.22 Logical Beginning of Tape (LBOT) 3

4.23 magnetic tape 3

4.24 Master Standard Amplitude Calibration Tape 3

4.25 Master Standard Reference Tape 3

4.26 Partition Boundary 3

4.27 Physical Beginning of Tape (PBOT) 3

4.28 Physical End of Tape (PEOT) 4

4.29 physical recording density 4

4.30 pre-recording condition 4

4.31 processing 4

4.32 processed data 4

4.33 Processed Record 4

4.34 record 4

4.35 Reference Field 4

4.36 Remote Memory In Cartridge (RMIC) 4

4.37 Secondary Standard Amplitude Calibration Tape 4

4.38 Secondary Standard Reference Tape 4

© ISO/IEC 2003 – All rights reserved iii

4.39 Separator Mark 4

4.40 Standard Reference Amplitude (SRA) 4

4.41 Standard Reference Current 4

4.42 Tape Reference Edge 4

4.43 Test Recording Current 4

4.44 track 5

4.45 Typical Field 5

4.46 unprocessed data 5

4.47 Unprocessed Record 5

5 Conventions and Notations 5

5.1 Representation of numbers 5

5.2 Names 5

6 Acronyms 5

7 Environment and safety 6

7.1 Test environment 6

7.2 Operating environment 6

7.3 Storage environment 6

7.4 Transportation 6

7.5 Safety 6

7.6 Flammability 6

Section 2 - Requirements for the case 6

8 Dimensional and mechanical characteristics of the case 6

8.1 General 6

8.2 Overall dimension 7

8.3 Holding areas 7

8.4 Cartridge insertion 8

8.5 Window 8

8.6 Loading grips 9

8.7 Label areas 9

8.8 Datum areas and Datum holes 9

8.9 Support areas 10

8.10 Recognition holes 10

8.11 Write-inhibit hole 11

8.12 Pre-positioning surfaces 12

8.13 Cartridge lid 12

8.14 Cartridge reel lock 13

8.15 Reel access holes 14

8.16 Interface between the reels and the drive spindles 14

8.17 Light path 15

8.18 Position of the tape in the case 16

8.19 Tape path zone 16

8.20 Tape access cavity 16

8.21 Tape access cavity clearance 17

8.22 Requirements for the RMIC 17

8.23 Recognition recesses 18

Section 3 - Requirements for the unrecorded tape 38

9 Mechanical, physical and dimensional characteristics of the tape 38

9.1 Materials 38

9.2 Tape length 38

iv © ISO/IEC 2003 – All rights reserved

9.2.1 Length of magnetic tape 38

9.2.2 Length of leader and trailer tapes 38

9.2.3 Length of the splicing tapes 38

9.3 Tape width 38

9.3.1 Width of magnetic, leader and trailer tapes 38

9.3.2 Width and position of the splicing tape 38

9.4 Discontinuities 39

9.5 Tape thickness 39

9.5.1 Thickness of the magnetic tape 39

9.5.2 Thickness of the leader and trailer tape 39

9.5.3 Thickness of the splicing tape 39

9.6 Longitudinal curvature 39

9.7 Cupping 39

9.8 Coating adhesion 39

9.9 Layer-to-layer adhesion 40

9.10 Tensile strength 40

9.10.1 Breaking strength 40

9.10.2 Yield strength 40

9.11 Residual elongation 40

9.12 Electrical resistance of the recording surface 40

9.13 Tape winding 41

9.14 Light transmittance of the tape 41

9.15 Recognition stripe 41

10 Magnetic recording characteristics 42

10.1 Typical Field 42

10.2 Signal Amplitude 42

10.3 Resolution 43

10.4 Overwrite 43

10.5 Ease of erasure 43

10.6 Tape quality 43

10.6.1 Missing pulses 43

10.6.2 Missing pulse zone 43

10.7 Signal-to-Noise Ratio (SNR) characteristic 43

Section 4 - Requirements for an interchanged tape 44

11 Format 44

11.1 General 44

11.2 Basic Groups 44

11.2.1 Entity 45

11.2.2 Group Information Table 45

11.2.3 Block Access Table (BAT) 48

11.3 Sub-Groups 50

11.3.1 G1 Sub-Group 50

11.3.2 G2 Sub-Group - Randomizing 51

11.3.3 G3 Sub-Group 52

11.4 Data Block 53

11.4.1 ID information 53

11.4.2 Recording of the ID Information in the Data Block Headers 56

12 Method of recording 61

12.1 Physical recording density 62

12.2 Long-term average bit cell length 62

12.3 Short-term average bit cell length 62

12.4 Rate of change 62

© ISO/IEC 2003 – All rights reserved v

12.5 Bit shift 62

12.6 Read signal amplitude 62

12.7 Maximum recorded levels 62

13 Track geometry 62

13.1 Track configuration 62

13.2 Average track pitch 63

13.3 Variations of the track pitch 63

13.4 Track width 63

13.5 Track angle 63

13.6 Track edge straightness 63

13.7 Track length 63

13.8 Azimuth angles 63

14 Recorded patterns 64

14.1 Recorded Data Block 64

15 Format of tracks 64

15.1 Track structure 64

15.2 Positioning accuracy 64

15.3 Tracking scheme 64

15.4 Generation of Margin Blocks 65

16 Layout of the tape 66

16.1 Device Area 66

16.2 Reference Area 67

16.3 Position Tolerance Band No. 1 67

16.4 System Area 67

16.4.1 System Preamble 67

16.4.2 System Log 67

16.4.3 System Postamble 72

16.4.4 Position Tolerance Band No. 2 72

16.4.5 Vendor Group Preamble 72

16.5 Data Area 72

16.5.1 Vendor Group 72

16.5.2 Recorded Data Group 72

16.5.3 ECC3 73

16.5.4 Multiple Recorded Instances 74

16.5.5 Repeated Frames 74

16.5.6 Appending and overwriting 75

16.6 EOD Area 76

16.7 Optional Device Area 76

16.8 Logical End Of Tape (LEOT) 77

16.9 Logical Beginning of Tape (LBOT) 77

16.10 Early Warning Point - EWP 77

16.11 Empty Partition 77

16.12 Initialization 77

17 Housekeeping Frames 78

17.1 Amble Frames 78

17.2 System Amble Frames 78

18 AIT Remote Memory In Cartridge (AIT RMIC) 78

18.1 General 78

18.2 Content of the AIT RMIC 78

18.2.1 Manufacturer's Information Section 79

vi © ISO/IEC 2003 – All rights reserved

18.2.2 Communication Information Section 82

18.2.3 Mechanism Error Log Information Section 82

18.2.4 Memory Management Information Section 83

18.2.5 Volume Information Section 84

18.2.6 Volume Use History Information Section 85

18.3 Memory Heap Management 85

18.3.1 Cell 85

18.3.2 Cell Header 85

18.3.3 Partition Information Cell 87

18.3.4 Physical Tape Directory Information Cell 87

18.3.5 User Volume Information Cell 88

18.3.6 User Partition Information Cell 88

18.3.7 Application Information Cell 89

18.3.8 Date and Time Stamp Information Cell 90

18.3.9 Media Identification Information Cell 91

18.3.10 Tape Alert Information Cell 91

18.4 Electrical interface 92

18.5 Environment 92

18.5.1 Electromagnetic Compatibility 92

18.5.2 Magnetic fields 92

18.5.3 X-rays 92

18.6 Operating Field 92

18.7 Message from AIT RMIC reader-writer to AIT RMIC 92

18.8 Message from AIT RMIC to AIT RMIC reader-writer 93

18.8.1 Load modulation 94

18.9 EDC 95

18.10 AIT RMIC states 95

18.11 Command and Response 96

18.11.1 Attention Command and Response 97

18.11.2 Attention Command and Response Type 1 97

18.11.3 Attention Command and Response Type 2 97

18.11.4 Read Command and Response 98

18.11.5 Write Command and Response 98

18.11.6 Status Command and Response 98

18.11.7 Reset Command and Response 99

18.12 Dialogue 99

18.12.1 Read data from AIT RMIC 99

18.12.2 WritedatatoAIT RMIC 100

18.12.3 Read and Write with Session ID 101

Annexes

A (normative) - Measurement of light transmittance 105

B (normative) - Measurement of Signal-to-Noise Ratio 108

C (normative) - Method for determining the nominal and the maximum allowable recorded levels

(pre-recording condition) 109

D (normative) - Representation of 16-bit words by 18-Channel bits patterns 110

E (normative) - Measurement of bit shift 111

F (normative) - Method of measuring the straightness of track edges 113

G (normative) - ECC calculation 114

H (informative) - Recommendations for transportation 117

J (informative) - Read-After-Write 118

© ISO/IEC 2003 – All rights reserved vii

K (informative) - Basic Group No. 0 119

L (informative) - Chip for the AIT-3 format 120

M (informative) - Generation of EDC bytes for the Error Detecting Code for G2 Sub-Groups 121

viii © ISO/IEC 2003 – All rights reserved

Foreword

ISO (the International Organization for Standardization) and IEC (the International Electrotechnical Commission) form the

specialized system for worldwide standardization. National bodies that are members of ISO or IEC participate in the

development of International Standards through technical committees established by the respective organization to deal with

particular fields of technical activity. ISO and IEC technical committees collaborate in fields of mutual interest. Other

international organizations, governmental and non-governmental, in liaison with ISO and IEC, also take part in the work. In

the field of information technology, ISO and IEC have established a joint technical committee, ISO/IEC JTC 1.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of the joint technical committee is to prepare International Standards. Draft International Standards adopted by

the joint technical committee are circulated to national bodies for voting. Publication as an International Standard requires

approval by at least 75 % of the national bodies casting a vote.

ISO/IEC 23651 was prepared by ECMA (as ECMA-329) and was adopted, under a special “fast-track procedure”, by Joint

Technical Committee ISO/IEC JTC 1, Information technology, in parallel with its approval by national bodies of ISO and IEC.

© ISO/IEC 2003 – All rights reserved ix

INTERNATIONAL STANDARD ISO/IEC 23651:2003(E)

Information technology — 8 mm wide magnetic tape cartridge for information

interchange — Helical scan recording — AIT-3 format

Section 1 - General

1Scope

This International Standard specifies the physical and magnetic characteristics of an 8 mm wide magnetic tape cartridge

containing a memory chip to enable physical interchange of such cartridges between drives. It also specifies the quality of the

recorded signals, the recording method and the recorded format - called Advanced Intelligent Tape No. 3 (AIT-3 format) -

thereby allowing data interchange between drives by means of such magnetic tape cartridges.

This International Standard specifies two types of cartridge depending on the thickness of the magnetic tape contained in the

case.

Information interchange between systems also requires, at a minimum, agreement between the interchange parties upon the

interchange code(s) and the specifications of the structure and labelling of the information on the interchanged cartridge.

2 Conformance

2.1 Magnetic tape cartridge

A tape cartridge shall be in conformance with this International Standard if it meets all the mandatory requirements specified

herein. The tape requirements shall be satisfied throughout the extent of the tape.

2.2 Generating drive

A drive generating a magnetic tape cartridge for interchange shall be in conformance with this International Standard if all

recordings on the tape meet the mandatory requirements of this International Standard, and if either one or both methods of

appending and overwriting are implemented. In addition, such a drive shall be able to record the System Log in the AIT

Remote Memory In Cartridge (AIT RMIC).

A claim of conformance shall state which of the following optional features are implemented and which are not

− the performing of a Read-After-Write check and the recording of any necessary repeated frames;

− the generation of ECC3 Frames.

In addition a claim of conformance shall state

− whether or not one, or more, registered algorithm(s) are implemented within the system and are able to compress data

received from the host prior to collecting the data into Basic Groups, and

− the registered identification number(s) of the implemented compression algorithm(s).

2.3 Receiving drive

A drive receiving a magnetic tape cartridge for interchange shall be in conformance with this International Standard if it is able

to handle any recording made on the tape according to this International Standard. In particular it shall

− be able to read the System Log recorded in the AIT RMIC;

− be able to recognise repeated frames, and to make available to the host, data and Separator Marks from only one of these

frames;

− be able to recognise multiple representations of the same Basic Group, and to make available to the host, data and

Separator Marks from only one of these representations;

− be able to recognise an ECC3 frame, and ignore it if the system is not capable of using ECC

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.