ISO/TS 19713-2:2010

(Main)Road vehicles — Inlet air cleaning equipment for internal combustion engines and compressors — Part 2: Fractional efficiency testing with coarse particles (5 µm to 40 µm optical diameter)

Road vehicles — Inlet air cleaning equipment for internal combustion engines and compressors — Part 2: Fractional efficiency testing with coarse particles (5 µm to 40 µm optical diameter)

ISO/TS 19713-2:2010 describes laboratory test methods to measure engine air cleaner and filter performance by fractional efficiency tests for particles from 5 µm to 40 µm, using ISO 12103-1 test dusts. Performance includes, but is not limited to, airflow restriction or pressure loss, initial and incremental fractional efficiencies during dust loading. ISO/TS 19713-1 describes fractional efficiency tests for particles from 0,3 µm to 5 µm optical diameter.

Véhicules routiers — Équipement d'épuration d'air d'entrée pour moteurs à combustion interne et compresseurs — Partie 2: Contrôle d'efficacité fractionnelle avec grosses particules (diamètre optique de 5 µm à 40 µm)

General Information

Standards Content (Sample)

TECHNICAL ISO/TS

SPECIFICATION 19713-2

First edition

2010-07-15

Road vehicles — Inlet air cleaning

equipment for internal combustion

engines and compressors —

Part 2:

Fractional efficiency testing with coarse

particles (5 µm to 40 µm optical diameter)

Véhicules routiers — Équipement d'épuration d'air d'entrée pour

moteurs à combustion interne et compresseurs —

Partie 2: Contrôle d'efficacité fractionnelle avec grosses particules

(diamètre optique de 5 µm à 40 µm)

Reference number

©

ISO 2010

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2010

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2010 – All rights reserved

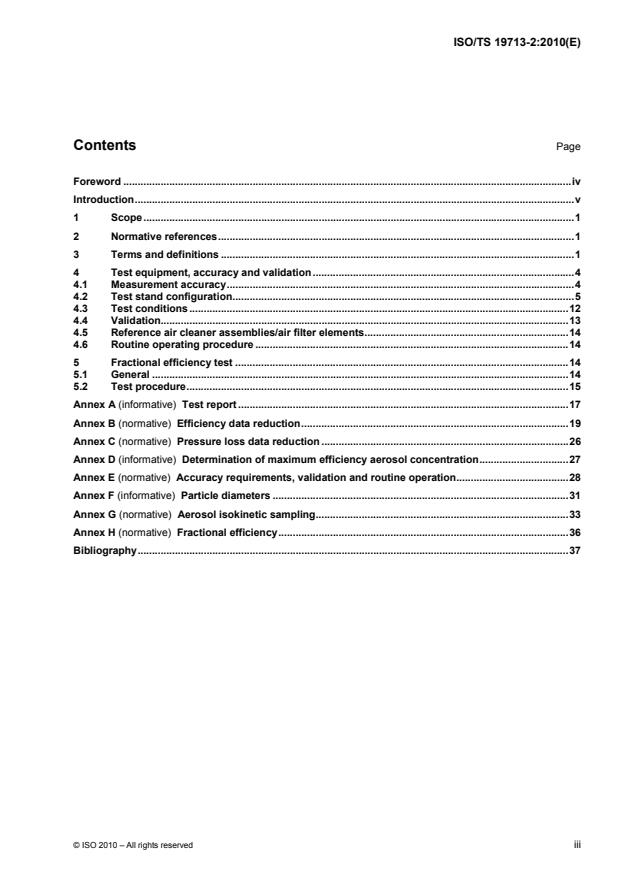

Contents Page

Foreword .iv

Introduction.v

1 Scope.1

2 Normative references.1

3 Terms and definitions .1

4 Test equipment, accuracy and validation.4

4.1 Measurement accuracy.4

4.2 Test stand configuration.5

4.3 Test conditions .12

4.4 Validation.13

4.5 Reference air cleaner assemblies/air filter elements.14

4.6 Routine operating procedure .14

5 Fractional efficiency test .14

5.1 General .14

5.2 Test procedure.15

Annex A (informative) Test report .17

Annex B (normative) Efficiency data reduction.19

Annex C (normative) Pressure loss data reduction .26

Annex D (informative) Determination of maximum efficiency aerosol concentration.27

Annex E (normative) Accuracy requirements, validation and routine operation.28

Annex F (informative) Particle diameters .31

Annex G (normative) Aerosol isokinetic sampling.33

Annex H (normative) Fractional efficiency.36

Bibliography.37

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

In other circumstances, particularly when there is an urgent market requirement for such documents, a

technical committee may decide to publish other types of document:

⎯ an ISO Publicly Available Specification (ISO/PAS) represents an agreement between technical experts in

an ISO working group and is accepted for publication if it is approved by more than 50 % of the members

of the parent committee casting a vote;

⎯ an ISO Technical Specification (ISO/TS) represents an agreement between the members of a technical

committee and is accepted for publication if it is approved by 2/3 of the members of the committee casting

a vote.

An ISO/PAS or ISO/TS is reviewed after three years in order to decide whether it will be confirmed for a

further three years, revised to become an International Standard, or withdrawn. If the ISO/PAS or ISO/TS is

confirmed, it is reviewed again after a further three years, at which time it must either be transformed into an

International Standard or be withdrawn.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO/TS 19713-2 was prepared by Technical Committee ISO/TC 22, Road vehicles, Subcommittee SC 7,

Injection equipment and filters for use on road vehicles.

ISO/TS 19713 consists of the following parts, under the general title Road vehicles — Inlet air cleaning

equipment for internal combustion engines and compressors:

⎯ Part 1: Fractional efficiency testing with fine particles (0,3 µm to 5 µm optical diameter)

⎯ Part 2: Fractional efficiency testing with coarse particles (5 µm to 40 µm optical diameter)

iv © ISO 2010 – All rights reserved

Introduction

The engine air cleaner/filter fractional efficiency test methods described in this part of ISO/TS 19713 have

been developed to cover traditional and new particulate air filters in order to remove airborne contaminants

specifically to protect the engine.

Air cleaner fractional efficiency is one of the main air cleaner performance characteristics. This part of

ISO/TS 19713 has been established to address the measurement of this parameter. The objective of the

procedure is to maintain a uniform test method for evaluating fractional efficiency of air cleaners and air filters

on specified laboratory test stands.

The data collected in accordance with this part of ISO/TS 19713 can be used to establish fractional efficiency

characteristics for air cleaners and filters tested in this manner. The actual field operating conditions (including

contaminants, humidity, temperature, mechanical vibration, flow pulsation, etc.) are difficult to duplicate.

However, with the procedure and equipment set forth, comparison of air filter fractional efficiency can be made

with a high degree of confidence.

TECHNICAL SPECIFICATION ISO/TS 19713-2:2010(E)

Road vehicles — Inlet air cleaning equipment for internal

combustion engines and compressors —

Part 2:

Fractional efficiency testing with coarse particles (5 µm to

40 µm optical diameter)

1 Scope

This part of ISO/TS 19713 describes laboratory test methods to measure engine air cleaner and filter

performance by fractional efficiency tests for particles from 5 µm to 40 µm, using ISO 12103-1 test dusts.

Performance includes, but is not limited to, airflow restriction or pressure loss, initial and incremental fractional

efficiencies during dust loading.

ISO/TS 19713-1 describes fractional efficiency tests for particles from 0,3 µm to 5 µm optical diameter.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 5011:2000, Inlet air cleaning equipment for internal combustion engines and compressors —

Performance testing

ISO 12103-1, Road vehicles — Test dust for filter evaluation — Part 1: Arizona test dust

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

air cleaner assembly

assembly which includes the air cleaner housing and the air filter element

3.1.1

single-stage air cleaner

air cleaner which does not incorporate a separate pre-cleaner

3.1.2

multistage air cleaner

air cleaner consisting of two or more stages, the first usually being a pre-cleaner, followed by one or more

filter elements

NOTE If two elements are used, the first is called the primary element and the second is called the secondary element.

3.1.3

pre-cleaner

device usually using inertial or centrifugal means to remove a portion of the test dust before reaching the filter

element

3.2

air filter element

actual filter supported and sealed within the air cleaner assembly

3.3

test airflow rate

measure of the volume of air passing through the test duct per unit time

NOTE The test airflow rate is expressed in cubic metres per second.

3.4

pressure loss

permanent pressure reduction due to a decrease in the flow energy (velocity head) caused by the filter (Pa at

standard conditions of 20 °C and 101,3 kPa)

3.5

fractional efficiency

E

f,i

ability of the air filter to remove particles of a specified size expressed as a percentage for particle size i

−

CC

1,ii2,

=×100 (1)

E

f,i

C

1,i

where

C is the number of particles per unit volume of specified size, i, upstream;

1,i

C is the number of particles per unit volume of specified size, i, downstream

2,i

NOTE Fractional efficiency is expressed in percent.

3.6

fractional efficiency before dust loading

efficiency before the collected particles have any measurable effect on the efficiency of the filter under test

NOTE The collected particles can affect the measured filter efficiency before enough aerosol is collected to have any

measurable effect on the filter pressure loss.

3.7

incremental fractional efficiency

efficiency, determined at the specified flow rate as a function of particle size at 10 %, 25 %, 50 % and 100 %

of filter life, which is determined by pressure loss across the filter as the filter is loaded with ISO 12103-1 test

dust

NOTE 1 The values of filter pressure loss, ∆P , at which the incremental fractional efficiencies are measured can be

i

calculated from

∆=P ∆PL+∆()∆P−∆P (2)

iiodo

where

∆P is the initial pressure loss;

o

2 © ISO 2010 – All rights reserved

∆L is the fraction of filter life;

i

∆P is the specified terminal pressure loss.

d

NOTE 2 If necessary, the requester and the tester can agree upon different criteria for incremental fractional efficiency.

3.8

fractional penetration

P

f,i

ratio of the concentration of particles of specified size exiting the filter to the concentration of particles of

specified size entering the filter expressed in a percentage for particle size i

PE=−100 (3)

f,iif,

NOTE Fractional penetration is expressed in percent.

3.9

test dust loading

mass of test dust collected by the air cleaner assembly or air filter element at a specified flow rate expressed

in grams

3.10

particle measurement device

aerosol spectrometer

instrument for sizing, or counting, or sizing and counting, aerosol particles

NOTE Recommended particle counters are optical particle counters (OPC) or other counters demonstrating good

correlation in measuring particle sizes, e.g. aerodynamic particle counters (APC).

3.11

test aerosol

particles suspended in air, used for filter efficiency evaluation or dust loading

3.11.1

fractional efficiency test aerosol

aerosol used t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.