ISO 18211:2016

(Main)Non-destructive testing — Long-range inspection of above-ground pipelines and plant piping using guided wave testing with axial propagation

Non-destructive testing — Long-range inspection of above-ground pipelines and plant piping using guided wave testing with axial propagation

ISO 18211:2016 specifies a method for long-range testing of carbon and low-alloy steel above-ground pipelines and plant piping using guided ultrasonic waves with axial propagation applied on the entire circumferential pipe section, in order to detect corrosion or erosion damage. The guided wave testing (GWT) method allows for fast inspection of above-ground pipelines, plant piping and cased road crossings, giving a qualitative screening and localization of probable corroded and eroded areas. GWT is typically performed on operating piping systems. ISO 18211:2016 is applicable to the following types of pipes: a) above-ground painted pipelines; b) above-ground insulated pipelines; c) painted plant piping; d) insulated plant piping. NOTE Pipe sections within road crossings with external casings (without bitumen or plastic coating) are a special case of buried pipe where there is no soil pressure on the OD of the pipe. ISO 18211 :2016 applies to these cased road crossings. Other types of pipes not included in the above list need dedicated approaches due to increased complexity.

Essais non destructifs — Vérification à large échelle des réseaux de canalisations hors sol et de la tuyauterie d'usine utilisant un essai d'onde guidée à propagation axiale

General Information

Relations

Standards Content (Sample)

DRAFT INTERNATIONAL STANDARD ISO/DIS 18211.2

Secretariat: IIW

Voting begins on Voting terminates on

2015-06-29 2015-08-29

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION МЕЖДУНАРОДНАЯ ОРГАНИЗАЦИЯ ПО СТАНДАРТИЗАЦИИ ORGANISATION INTERNATIONALE DE NORMALISATION

Non-destructive testing — Long range inspection of above

ground pipelines and plant piping using guided wave testing

with axial propagation

Titre manque

Partie #: Titre de la partie

ICS 19.100

Member bodies are requested to consult relevant national interests in ISO/TC 44/SC ## before

returning their ballot to the ISO Central Secretariat.

This draft International Standard is submitted to all ISO member bodies for voting, as a

standard prepared by an international standardizing body in accordance with Council

Resolution 42/1999. The proposer, the International Institute of Welding (IIW), has been

recognized by the ISO Council as an international standardizing body for the purpose of

Council Resolution 42/1999.

To expedite distribution, this document is circulated as received from the committee

secretariat. ISO Central Secretariat work of editing and text composition will be undertaken at

publication stage.

THIS DOCUMENT IS A DRAFT CIRCULATED FOR COMMENT AND APPROVAL. IT IS THEREFORE SUBJECT TO CHANGE AND MAY NOT BE

REFERRED TO AS AN INTERNATIONAL STANDARD UNTIL PUBLISHED AS SUCH.

IN ADDITION TO THEIR EVALUATION AS BEING ACCEPTABLE FOR INDUSTRIAL, TECHNOLOGICAL, COMMERCIAL AND USER PURPOSES,

DRAFT INTERNATIONAL STANDARDS MAY ON OCCASION HAVE TO BE CONSIDERED IN THE LIGHT OF THEIR POTENTIAL TO BECOME

STANDARDS TO WHICH REFERENCE MAY BE MADE IN NATIONAL REGULATIONS.

RECIPIENTS OF THIS DRAFT ARE INVITED TO SUBMIT, WITH THEIR COMMENTS, NOTIFICATION OF ANY RELEVANT PATENT RIGHTS OF WHICH

THEY ARE AWARE AND TO PROVIDE SUPPORTING DOCUMENTATION.

© International Organization for Standardization, 2015

ISO/DIS 18211.2

© ISO 2015

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form or by any

means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior written permission.

Permission can be requested from either ISO at the address below or ISO’s member body in the country of the requester.

ISO copyright office

Case postale 56 CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2015 – All rights reserved

ISO/DIS 18211.2

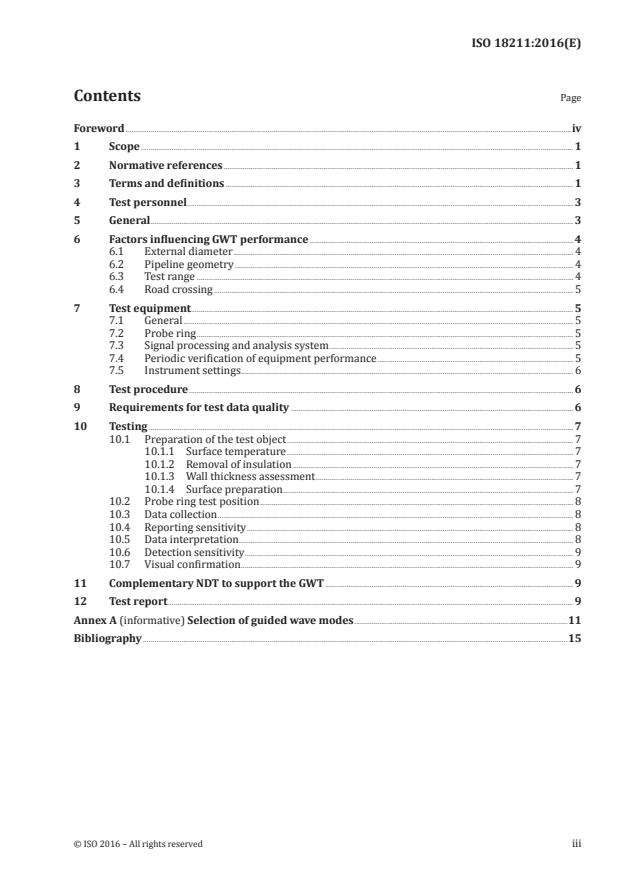

Contents Page

Foreword . iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Test personnel . 3

5 General . 3

6 Factors influencing GWT performance . 4

6.1 External diameter . 4

6.2 Pipeline geometry . 4

6.3 Test range . 4

6.4 Road crossing . 5

7 Test equipment . 5

7.1 General . 5

7.2 Probe ring . 5

7.3 Signal processing and analysis system . 6

7.4 Periodic verification of equipment performance . 6

7.5 Settings . 6

8 Test procedure . 6

9 Requirements for test data quality . 7

10 Testing . 7

10.1 Preparation of the test object . 7

10.1.1 Surface temperature . 7

10.1.2 Removal of insulation . 7

10.1.3 Wall thickness assessment . 8

10.1.4 Surface preparation . 8

10.2 Probe ring test position . 8

10.3 Data Collection . 8

10.4 Reporting sensitivity . 8

10.5 Data interpretation . 9

10.6 Detection sensitivity . 9

10.7 Visual confirmation . 9

11 Complementary NDT to support the GWT . 9

12 Test report . 10

Annex A (informative) Selection of guided wave modes . 11

Bibliography . 15

ISO/DIS 18211.2

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 18211 was prepared by IIW, the International Institute of Welding.

iv © ISO 2015 – All rights reserved

DRAFT INTERNATIONAL STANDARD ISO/DIS 18211.2

Non-destructive testing — Long range Inspection of above

ground pipelines and plant piping using guided wave testing

with axial propagation

1 Scope

This International Standard specifies a method for long range testing of carbon and low alloy steel above

ground pipelines and plant piping using guided ultrasonic waves with axial propagation applied on the entire

circumferential pipe section, in order to detect corrosion or erosion damage.

The Guided Wave Testing (GWT) technique allows for fast inspection of above ground pipelines, plant piping

and cased road crossings, giving a qualitative screening and localization of probable corroded and eroded

areas. GWT is typically performed on operating piping systems.

This International Standard can be applied to the following types of pipes:

a) above ground painted pipelines;

b) above ground insulated pipelines;

c) pipe sections within road crossings with external casing (without bitumen or plastic coating);

d) painted plant piping;

e) insulated plant piping.

Other types of pipes not included in the above list need dedicated approaches due to increased complexity.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 9712, Non-destructive testing – Qualification and certification of personnel

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

axial direction

the direction along the main axis of the pipe

3.2

circumferential direction

the direction around the circumference of the pipe

ISO/DIS 18211.2

3.3

total pipe wall cross-section (TCS)

the area between the inner and outer diameters of the pipe in a plane perpendicular to the pipe axis

3.4

cross-section change

the equivalent cross-section change calculated assuming that an indication is purely caused by a change in

the cross-section of the pipe wall

3.5

datum point

reference point for reporting a test position and for correlating test results with the corresponding position on

the test object

3.6

dead zone

length of pipe on either side of the test position where reflectors of interest cannot be detected because they

are covered by the transmitted pulse

3.7

flexural mode

a non-symmetric bending type mode of guided wave propagation in pipes, with particle displacements in axial,

circumferential and radial directions

3.8

focus

concentration of guided waves at a single axial and circumferential position, achieved either by hardware

settings or by post-processing of a recorded set of signals (synthetic focus)

3.9

geometric feature

pipeline feature (i.e. weld, support, flange, bend, etc.) causing the reflection of guided waves because of a

cross section change or other acoustic impedance variation

3.10

guided wave mode

distinct type of guided wave with a specific vibration pattern

3.11

longitudinal mode

a symmetric compression type mode of guided wave propagation in pipes, with particle displacements

predominantly in the axial direction

3.12

primary mode

guided wave mode which is chosen for the incident wave

3.13

probe ring

circumferential component, containing transducer elements with direct contact to the pipe

3.14

secondary mode

guided wave mode which is different from the primary mode and is generated by mode conversion at pipe

features or discontinuities

3.15

test frequency

centre frequency of the pulses transmitted by the probe ring

ISO/DIS 18211.2

3.16

test position

axial position on the pipe where the probe ring is place

3.17

test range

the distance between the test position and the furthest position for which the minimum acceptable sensitivity

of the reference signal is achieved, in each direction (positive or negative)

3.18

torsional mode

a symmetric twisting type mode of guided wave propagation in pipes, with particle displacements in the

circumferential direction

4 Test personnel

The personnel performing ultrasonic guided wave testing shall be qualified in accordance with ISO 9712 or

with any another equivalent standard of the relevant industrial sector.

Training in the use of the specific equipment is required because there are significant differences between the

available systems and diagnostic approaches.

5 General

Ultrasonic Guided Wave Testing (GWT) uses elastic waves which are guided along the pipe wall and can

travel long distances, thus providing rapid near complete coverage of the volume of the pipe wall.

The typical test setup is comparable to conventional ultrasonic pulse-echo testing: an ultrasonic instrument

forces transducers in the probe ring to generate ultrasonic waves in the pipe wall which are reflected by

discontinuities and received by the same probe ring. The time-of-flight of the received signal indicates the

distance between the discontinuities and the probe ring. A single test with guided waves can cover a length of

pipe

...

INTERNATIONAL ISO

STANDARD 18211

First edition

2016-07-15

Non-destructive testing — Long-range

inspection of above-ground pipelines

and plant piping using guided wave

testing with axial propagation

Essais non destructifs — Vérification à large échelle des réseaux de

canalisations hors sol et de la tuyauterie d’usine utilisant un essai

d’onde guidée à propagation axiale

Reference number

©

ISO 2016

© ISO 2016, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2016 – All rights reserved

Contents Page

Foreword .iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Test personnel . 3

5 General . 3

6 Factors influencing GWT performance . 4

6.1 External diameter . 4

6.2 Pipeline geometry . 4

6.3 Test range . 4

6.4 Road crossing . 5

7 Test equipment. 5

7.1 General . 5

7.2 Probe ring . 5

7.3 Signal processing and analysis system . 5

7.4 Periodic verification of equipment performance . 5

7.5 Instrument settings . 6

8 Test procedure . 6

9 Requirements for test data quality . 6

10 Testing . 7

10.1 Preparation of the test object . 7

10.1.1 Surface temperature . 7

10.1.2 Removal of insulation . 7

10.1.3 Wall thickness assessment . 7

10.1.4 Surface preparation . 7

10.2 Probe ring test position . 8

10.3 Data collection . 8

10.4 Reporting sensitivity . 8

10.5 Data interpretation . 8

10.6 Detection sensitivity . 9

10.7 Visual confirmation . 9

11 Complementary NDT to support the GWT . 9

12 Test report . 9

Annex A (informative) Selection of guided wave modes .11

Bibliography .15

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity assessment,

as well as information about ISO’s adherence to the World Trade Organization (WTO) principles in the

Technical Barriers to Trade (TBT) see the following URL: www.iso.org/iso/foreword.html.

The committee responsible for this document is IIW, International Institute of Welding, Commission V.

Requests for official interpretations of any aspect of this International Standard should be directed to

the ISO Central Secretariat, who will forward them to the IIW Secretariat for an official response.

iv © ISO 2016 – All rights reserved

INTERNATIONAL STANDARD ISO 18211:2016(E)

Non-destructive testing — Long-range inspection of above-

ground pipelines and plant piping using guided wave

testing with axial propagation

1 Scope

This International Standard specifies a method for long-range testing of carbon and low-alloy steel

above-ground pipelines and plant piping using guided ultrasonic waves with axial propagation applied

on the entire circumferential pipe section, in order to detect corrosion or erosion damage.

The guided wave testing (GWT) method allows for fast inspection of above-ground pipelines, plant

piping and cased road crossings, giving a qualitative screening and localization of probable corroded

and eroded areas. GWT is typically performed on operating piping systems.

This International Standard is applicable to the following types of pipes:

a) above-ground painted pipelines;

b) above-ground insulated pipelines;

c) painted plant piping;

d) insulated plant piping.

NOTE Pipe sections within road crossings with external casings (without bitumen or plastic coating) are

a special case of buried pipe where there is no soil pressure on the OD of the pipe. This International Standard

applies to these cased road crossings.

Other types of pipes not included in the above list need dedicated approaches due to increased

complexity.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 9712, Non-destructive testing — Qualification and certification of NDT personnel

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

axial direction

direction along the main axis of the pipe

3.2

circumferential direction

direction around the circumference of the pipe

3.3

total pipe wall cross-section

TCS

area between the inner and outer diameters of the pipe in a plane perpendicular to the pipe axis

3.4

cross-section change

equivalent cross-section change calculated assuming that an indication is purely caused by a change in

the cross-section of the pipe wall

3.5

datum point

reference point for reporting a test position (3.16) and for correlating test results with the corresponding

position on the test object

3.6

dead zone

length of pipe on either side of the test position (3.16) where reflectors of interest cannot be detected

because they are covered by the transmitted pulse

3.7

flexural mode

non-symmetric bending type mode of guided wave propagation in pipes, with particle displacements in

axial, circumferential and radial directions

3.8

focus

concentration of guided waves at a single axial and circumferential position, achieved either by

hardware settings or by post-processing of a recorded set of signals (synthetic focus)

3.9

geometric feature

pipeline feature (e.g. weld, support, flange, bend, etc.) causing the reflection of guided waves because of

a cross-section change (3.4) or other acoustic impedance variation

3.10

guided wave mode

distinct type of guided wave with a specific vibration pattern

3.11

longitudinal mode

symmetric compression type mode of guided wave propagation in pipes, with particle displacements

predominantly in the axial direction (3.1)

3.12

primary mode

guided wave mode (3.10) which is chosen for the incident wave

3.13

probe ring

circumferential component, containing transducer elements with direct contact to the pipe

3.14

secondary mode

guided wave mode (3.10) which is different from the primary mode (3.12) and is generated by mode

conversion at pipe features or discontinuities

3.15

test frequency

centre frequency of the pulses transmitted by the probe ring (3.13)

3.16

test position

axial position on the pipe where the probe ring (3.13) is placed

2 © ISO 2016 – All rights reserved

3.17

test range

distance between the test position (3.16) and the furthest position for which the minimum acceptable

sensitivity of the referenc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.