ISO 13470:2012

(Main)Trenchless applications of ductile iron pipes systems — Product design and installation

Trenchless applications of ductile iron pipes systems — Product design and installation

1 Scope This International Standard specifies the requirements, test methods and installation technologies applicable to ductile iron pipes used in trenchless applications: — to convey water or wastewater; — operated with or without pressure. NOTE In this International Standard, all pressures are relative pressures expressed in bar(s)1). This International Standard specifies materials, dimensions and tolerances, mechanical properties and standard coatings of pipes, fittings and accessories. It also gives performance requirements for all components including joints. Joint design and gasket shapes are outside the scope of this International Standard. This International Standard applies to pipes, fittings and accessories cast by any type of foundry process or manufactured by fabrication of cast components, as well as corresponding joints, of a size range DN 80 to DN 2 600 inclusive.

Application des systèmes de canalisations en fonte ductile en pose sans tranchée — Conception des produits et mise en oeuvre

General Information

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 13470

First edition

2012-07-01

Trenchless applications of ductile iron

pipes systems — Product design and

installation

Application des systèmes de canalisations en fonte ductile en pose

sans tranchée — Conception des produits et mise en oeuvre

Reference number

©

ISO 2012

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or ISO’s

member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2012 – All rights reserved

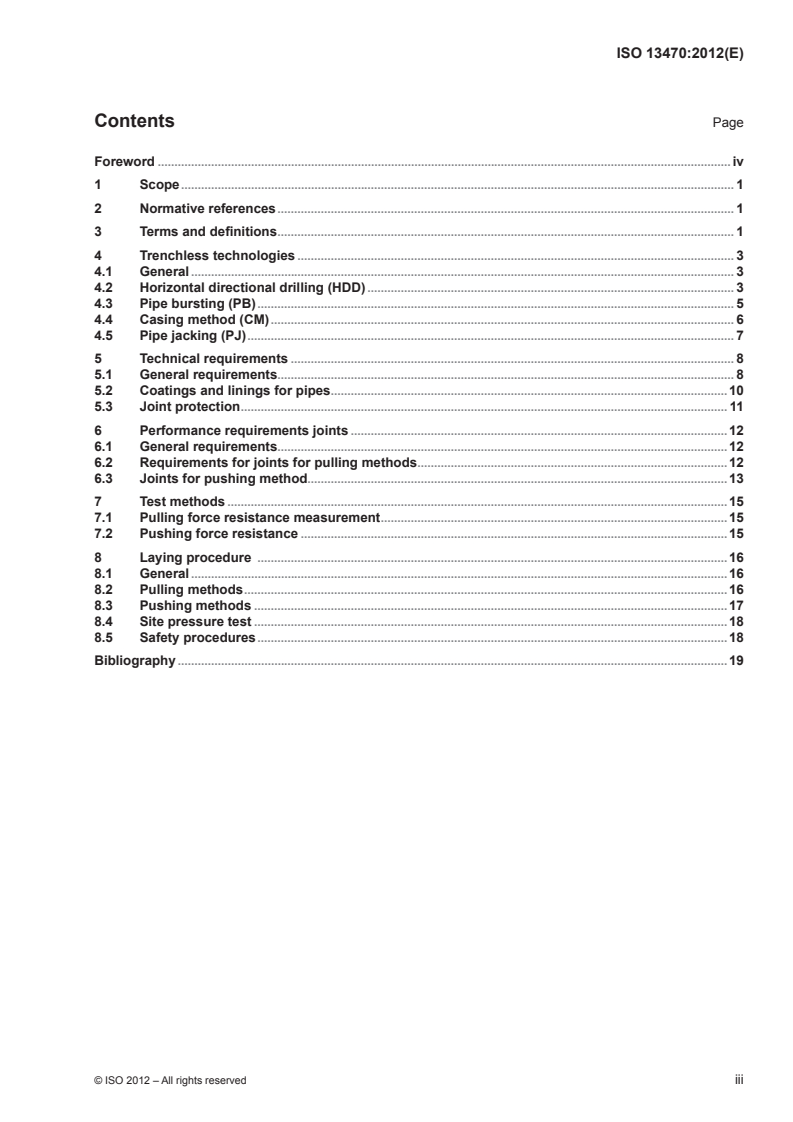

Contents Page

Foreword .iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Trenchless technologies . 3

4.1 General . 3

4.2 Horizontal directional drilling (HDD) . 3

4.3 Pipe bursting (PB) . 5

4.4 Casing method (CM) . 6

4.5 Pipe jacking (PJ) . 7

5 Technical requirements . 8

5.1 General requirements . 8

5.2 Coatings and linings for pipes .10

5.3 Joint protection . 11

6 Performance requirements joints .12

6.1 General requirements .12

6.2 Requirements for joints for pulling methods .12

6.3 Joints for pushing method.13

7 Test methods .15

7.1 Pulling force resistance measurement .15

7.2 Pushing force resistance .15

8 Laying procedure .16

8.1 General .16

8.2 Pulling methods .16

8.3 Pushing methods .17

8.4 Site pressure test .18

8.5 Safety procedures .18

Bibliography .19

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the International

Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 13470 was prepared by Technical Committee ISO/TC 5, Ferrous metal pipes and metallic fittings,

Subcommittee SC 2, Cast iron pipes, fittings and their joints.

iv © ISO 2012 – All rights reserved

INTERNATIONAL STANDARD ISO 13470:2012(E)

Trenchless applications of ductile iron pipes systems —

Product design and installation

1 Scope

This International Standard specifies the requirements, test methods and installation technologies applicable

to ductile iron pipes used in trenchless applications:

— to convey water or wastewater;

— operated with or without pressure.

1)

NOTE In this International Standard, all pressures are relative pressures expressed in bar(s) .

This International Standard specifies materials, dimensions and tolerances, mechanical properties and

standard coatings of pipes, fittings and accessories. It also gives performance requirements for all components

including joints.

Joint design and gasket shapes are outside the scope of this International Standard.

This International Standard applies to pipes, fittings and accessories cast by any type of foundry process or

manufactured by fabrication of cast components, as well as corresponding joints, of a size range DN 80 to DN

2 600 inclusive.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced document

(including any amendments) applies.

ISO 2531, Ductile iron pipes, fittings, accessories and their joints for water applications

ISO 7186, Ductile iron products for sewerage applications

ISO 8180, Ductile iron pipes — Polyethylene sleeving for site application

ISO 10804, Restrained joint systems for ductile iron pipelines — Design rules and type testing

EN 14628, Ductile iron pipes, fittings and accessories — External polyethylene coating for pipes — Requirements

and test methods

EN 15189, Ductile iron pipes, fittings and accessories — External polyurethane coating for pipes — Requirements

and test methods

EN 15542, Ductile iron pipes, fittings and accessories — External cement mortar coating for pipes —

Requirements and test methods

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

1) 100 kPa = 1 bar.

3.1

allowable angular deflection

angular deflection that a joint between two components can safely withstand in service under the allowable

operating pressure (PFA)

3.2

allowable pulling force

maximum pulling force that can be applied on a string of pipes during laying by horizontal directional drilling,

pipe bursting or casing technologies

3.3

allowable pushing force

maximum pushing force that can be applied on a string of pipes during laying by pipe jacking, pipe bursting or

casing technologies

3.4

bentonite

clay mineral, primarily montmorilonite, with high swelling properties, which forms the primary component in

drilling muds used in horizontal directional drilling technology

3.5

bore

cavity that is created to receive a pipe or conduit

3.6

casing

continuous structural shell that acts as an envelope and support for the service pipeline during construction

and service

3.7

casing method

method in which a casing is put into place and then a pipe is inserted into the casing

3.8

drilling fluid

fluid created by mixing water and bentonite as well as other additives to facilitate drilling and transport of drill

cuttings from the drill bit to the surface

3.9

horizontal directional drilling

steerable method for the underground installation of pipes using a surface launched drilling rig

3.10

pilot hole

initial bore drilled along the drill path

3.11

pipe bursting method

method for replacement of an existing pipe by longitudinal splitting

3.12

pipe jacking method

system of directly installing pipes behind a cutting head and/or shield, by hydraulic thrust

3.13

pulling head

reusable component mounted at the beginning of the pipe string, which transmits the pulling force from the

drilling rod to the pipes

3.14

service pipeline

ductile iron pipeline intended to carry water or wastewater, operated with or without pressure

2 © ISO 2012 – All rights reserved

3.15

sheath

coating, sleeving or encasement of the pipe body, which makes the profile uniformly cylindrical

See Figure 6.

3.16

trenchless technology

any technology for constructing pipelines in the ground without opening trenches

4 Trenchless technologies

4.1 General

This International Standard deals with the following trenchless technologies:

— horizontal directional drilling (HDD);

— pipe bursting (PB);

— casing method (CM);

— pipe jacking (PJ).

See Table 1.

Table 1 — Corresponding DNs for trenchless technologies

Pulling methods Pushing methods

Horizontal directional drilling (HDD) Yes No

DN 100 to DN 1 200

Pipe bursting (PB) Yes Yes

DN 100 to DN 1 200 DN 100 to DN 1 200

Casing method (CM) Yes Yes

DN 80 to DN 2 600 DN 80 to DN 2 600

Pipe jacking (PJ) No Yes

DN 250 to DN 2 600

4.2 Horizontal directional drilling (HDD)

4.2.1 General

HDD is a steerable trenchless method of installing underground pipes along a prescribed bore path by using

a surface launched drilling rig, with minimum impact on the environment (see Figure 1). Directional boring is

used where trenching or excavating is not practicable. It is suitable for a variety of soil conditions and projects,

including road and river crossings.

The sequence of operations is generally divided into three successive steps.

4.2.2 First step — Pilot bore

The pilot bore is the first step in producing a bore, running from the starting point to the arrival pit, and is driven

under steered control by a drilling head at the tip of a drilling string.

An aqueous suspension of bentonite emerges at high pressure from the drilling head, which

— drives the head forward,

— helps to cut the soil,

— carries away the cut material, and

— supports the bore.

The pilot bore is steered by controlled rotation of the drilling head; it is detected above the path of the bore by

radio signals, gyroscope or other means.

4.2.3 Second step — Upsize bore

During upsizing, an upsizing head is pulled through the bore, while rotating continuously; in this way, it enlarges

the size of the pilot bore.

The soil that is cut away is carried out with the drilling mud, which also supports the bore.

The upsizing process is repeated with increasingly larger heads until the bore is of the desired diameter.

4.2.4 Third step — Pulling in

For this third step, prior to pulling the pipes, three devices are attached to the drilling rods:

— a reaming tool;

— a rotary joint (which stops the string of pipes from turning with the reaming tool);

— a pulling head (connected to the string of pipes by mechanical locking).

As the pulling in progresses, drilling mud is pumped through the drilling linkage. It emerges from the reaming

tool, carrying away the soil and reducing the frictional forces.

Key

1 drilling unit

2 tunnel head earthworks

3 piloting the drill

4 tunnel exit earthworks

5 anchored joint ductile iron pipes

Figure 1 — Horizontal directional drilling method

4 © ISO 2012 – All rights reserved

4.3 Pipe bursting (PB)

4.3.1 General

The pipe bursting technique is used for the trenchless renovation of pipelines where the new pipeline is meant to

follow the same path as the old (see Figure 2). For this purpose, the existing old pipeline is destroyed by a bursting

head; at the same time, the fragments are pushed into the surrounding soil and the new run of pipe is pulled in.

Old pipes made of brittle as well as of ductile materials, such as steel or ductile iron pipes, may be renewed by

this process, where suitable bursting or cutting heads are used. Before the pipe bursting operation, the existing

profile of the piping shall be known. The trench shall be opened and the bends shall be removed. The valves

and the concrete block shall be removed.

The new pipe which is pulled in may be of the same nominal size as the old pipe or, as dictated by the widening

head which is used, of a larger size.

Because the soil conditions are generally unknown and, above all, because of the sharp-edged fragments,

which most certainly occur with the burst lining technique, care should be taken to see that the pipeline material

used is one which is not sensitive to factors of this kind.

With pipe bursting, a distinction is made between the dynamic and static variants.

4.3.2 Dynamic variant

Where using the dynamic variant, the force required for bursting is applied in the longitudinal direction of the

pipe using a suitable pneumatic bursting tool. This is driven by a compressor, which is connected to it by a

flexible hose. To guide the bursting head, it is pulled along by a winch from the arrival pit on a hook-equipped

pulling rope, which is pulled through the old pipe.

The dynamic variant is particularly suitable for highly compacted and stony soils.

4.3.3 Static variant

In this case, a widening head (the first widened part of which may be fitted with breaker ribs) is pulled through

the old pipeline from the pulling unit to the bursting head, which operates continuously and without any vibration,

and in this way, the old pipeline is burst open.

The new pipes are coupled straight to the bursting/widening head and are pulled into the bore, which is widened

to approximately a 10 % oversize.

The static variant is well suited to homogeneous soils, which can be easily displaced.

For ductile pipes (e.g. steel pipes and ductile iron pipes), a cutting head with roll knives cuts the pipe longitudinally,

with subsequent widening of the cut pipe. The new pipes are pulled into this widened pipe.

Key

1 starting point of earthworks

2 intermediate point of earthworks

3 exit point of earthworks

4 expansion cone and drawing tool

5 waste

6 bursting cone

7 traction rod segment

8 new ductile iron pipe

9 old pipe

Figure 2 — Pipe bursting method

4.4 Casing method (CM)

4.4.1 General

In the casing method, a casing is first installed through the soil, between two pits on the pipeline alignment

(see Figure 3). Ductile iron pipes are subsequently inserted through the casing, building the pipeline by adding

and jointing one pipe at a time. The process continues until the service pipeline is completed, at which time it

is connected and commissioned.

This method is also well established to renovate old pipelines for water or sewerage by pulling or pushing in

new pipes, where the hydraulic design allows a diminution of the internal diameter.

4.4.2 Installing the casing

The casing normally comprises 6 m long steel cylindrical shells or sections with a D/t (mean diameter divided

by the shell thickness) fraction/quotient of approximately 120 to 150. It is installed between a launching pit and

receiving pit. A hydraulic jack, surveying lasers and excavating and soil removal equipment are installed in the

launching pit.

Excavation can be carried out using various techniques depending on the size of the casing and the nature of the

soil. These techniques typically include water jetting, auguring and full face cutter heads. Soil removal is carried

out to match the excavation rate and includes such methods as slurry returns, augurs, conveyors and scrapers.

As the excavation progresses, the casing is jacked behind the excavation face and built up by welding on

subsequent sections, one at a time, in the launching pit.

6 © ISO 2012 – All rights reserved

4.4.3 Installing the service pipeline

The service pipeline may be assembled by push or pull. Most applications take advantage of flexible pipeline

joints and their ease of assembly. If the pull method is used, however, some means of anchoring the joints to

prevent separation is required. If the push technique is used, care should be taken not to damage the cement

mortar lining as the pipe spigot bears on the bottom of pipe socket.

The service pipeline is assembled very much like the casing, one pipe at a time, with the service pipeline being

pulled or pushed through the casing. To assist in this operation, it is advisable to use skids which set at 120°

around the pipe circumference and strapped to the ductile iron pipes at centres of 2 m. The typical frictional forces

required to be overcome may be estimated using a coefficient of friction of µ = 0,2 – 0,3 (greased wood on steel).

Pipe pulling installation in the casing may be achieved, either by using a pulling head or a rope encircling the

socket of the first pipe (see footnote a of Figure 3, which indicates the direction of pulling).

Key

1 casing

2 assembly tackle

3 guidance collar

4 restrained joint

a

Direction of pulling by rope.

Figure 3 — Casing method

4.5 Pipe jacking (PJ)

Pipe jacking involves pushing pipes through the ground (see Figure 4) with thrust provided by powerful hydraulic

jacks, while soil is excavated at the front of the pipe string.

A number of excavation methods are available for pipe jacking; the appropriate system should be used, taking

into account the soil conditions, jacking distance and pipe size.

Thrust and reception pits are constructed while this method is being used.

Key

1 control container

2 jacking pipes

3 plan view on launch shaft

4 launch shaft

5 jacking pipes

6 reception seal

7 jacking frame

8 lead pipe

Figure 4 — Pipe jacking method

5 Technical requirements

5.1 General requirements

5.1.1 General

Pipes, fittings and gaskets used in trenchless applications shall comply with

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.