ISO/TR 13624-2:2009

(Main)Petroleum and natural gas industries — Drilling and production equipment — Part 2: Deepwater drilling riser methodologies, operations, and integrity technical report

Petroleum and natural gas industries — Drilling and production equipment — Part 2: Deepwater drilling riser methodologies, operations, and integrity technical report

ISO/TR 13624-2:2009 pertains to mobile offshore drilling units that employ a subsea BOP stack deployed at the seafloor. It is intended that the drilling riser analysis methodologies discussed in this part of ISO 13624 be used and interpreted in the context of ISO 13624-1.

Industries du pétrole et du gaz naturel — Équipement de forage et de production — Partie 2: Méthodologies, opérations et rapport technique d'intégrité relatifs aux tubes prolongateurs pour forages en eaux profondes

General Information

Standards Content (Sample)

TECHNICAL ISO/TR

REPORT 13624-2

First edition

2009-12-01

Petroleum and natural gas industries —

Drilling and production equipment —

Part 2:

Deepwater drilling riser methodologies,

operations, and integrity technical report

Industries du pétrole et du gaz naturel — Équipement de forage et de

production —

Partie 2: Méthodologies, opérations et rapport technique d'intégrité

relatifs aux tubes prolongateurs pour forages en eaux profondes

Reference number

©

ISO 2009

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2009

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2009 – All rights reserved

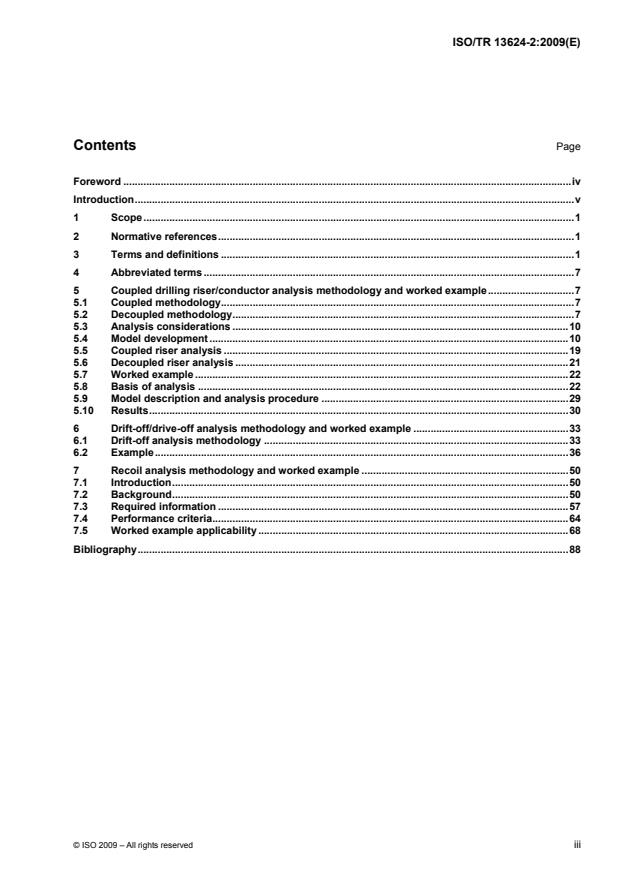

Contents Page

Foreword .iv

Introduction.v

1 Scope.1

2 Normative references.1

3 Terms and definitions .1

4 Abbreviated terms .7

5 Coupled drilling riser/conductor analysis methodology and worked example.7

5.1 Coupled methodology.7

5.2 Decoupled methodology.7

5.3 Analysis considerations .10

5.4 Model development.10

5.5 Coupled riser analysis .19

5.6 Decoupled riser analysis .21

5.7 Worked example .22

5.8 Basis of analysis .22

5.9 Model description and analysis procedure .29

5.10 Results.30

6 Drift-off/drive-off analysis methodology and worked example .33

6.1 Drift-off analysis methodology .33

6.2 Example.36

7 Recoil analysis methodology and worked example .50

7.1 Introduction.50

7.2 Background.50

7.3 Required information .57

7.4 Performance criteria.64

7.5 Worked example applicability .68

Bibliography.88

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

In exceptional circumstances, when a technical committee has collected data of a different kind from that

which is normally published as an International Standard (“state of the art”, for example), it may decide by a

simple majority vote of its participating members to publish a Technical Report. A Technical Report is entirely

informative in nature and does not have to be reviewed until the data it provides are considered to be no

longer valid or useful.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO/TR 13624-2 was prepared by Technical Committee ISO/TC 67, Materials, equipment and offshore

structures for petroleum, petrochemical and natural gas industries, Subcommittee SC 4, Drilling and

production equipment.

ISO/TR 13624 consists of the following parts, under the general title Petroleum and natural gas industries —

Drilling and production equipment:

⎯ Part 1: Design and operation of marine drilling riser equipment

⎯ Part 2: Deepwater drilling riser methodologies, operations, and integrity technical report

iv © ISO 2009 – All rights reserved

Introduction

Since API RP 16Q was issued in 1993, hydrocarbon exploration in 1 200+ m (4 000+ ft) water depths has

increased significantly. As a consequence, the need was identified to update that code of practice to address

the issues particular to deepwater operations.

Under the auspices of the DeepStar programme, substantial work was commissioned during 1999 and 2000

by the DeepStar Drilling Committee 4502 and led to the development of Deepwater Drilling Riser

Methodologies, Operations, and Integrity Guidelines in February 2001. Several contractors participated in

these efforts. These guidelines were intended to supplement and update the existing API RP 16Q:1993 for

deepwater application. In a subsequent joint industry project and in collaboration with DeepStar and the API,

these guidelines were later supplemented with other identified revisions and technically edited by an API task

group to produce the revision of API RP 16Q:1993 as ISO 13624-1 and the API Technical Report TR1.

This Technical Report is a supplement to the revised API RP 16Q and provides guidance on various analysis

methodologies and operating practices.

NOTE The figures have been reproduced as provided by the Technical Committee and, in some cases, contain only

USC units.

TECHNICAL REPORT ISO/TR 13624-2:2009(E)

Petroleum and natural gas industries — Drilling and production

equipment —

Part 2:

Deepwater drilling riser methodologies, operations, and

integrity technical report

1 Scope

This part of ISO 13624 pertains to mobile offshore drilling units that employ a subsea BOP stack deployed at

the seafloor. It is intended that the drilling riser analysis methodologies discussed in this part of ISO 13624 be

used and interpreted in the context of ISO 13624-1.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 13624-1:2009, Petroleum and natural gas industries — Drilling and production equipment —

Part 1: Design and operation of marine drilling riser equipment

API RP 16Q:1993, Design, Selection, Operation and Maintenance of Marine Drilling Riser Systems

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

accumulator

〈BOP〉 pressure vessel charged with gas (e.g. nitrogen) over liquid and used to store hydraulic fluid under

pressure for operation of blowout preventers

3.2

accumulator

riser tensioner

pressure vessel charged with gas (e.g. nitrogen) over liquid that is pressurized on the gas side from the

tensioner high-pressure gas supply bottles and supplies high-pressure hydraulic fluid to energize the riser

tensioner cylinder

3.3

air-can buoyancy

tension applied to the riser string by the net buoyancy of an air chamber created by a closed-top, open-bottom

cylinder forming an air-filled annulus around the outside of the riser pipe

3.4

annulus

space between two pipes, when one pipe is positioned inside the other

3.5

apparent weight

effective weight

submerged weight

riser weight in air minus buoyancy

NOTE Apparent weight is commonly referred to as weight in water, wet weight, submerged weight or effective weight.

3.6

auxiliary line

conduit (excluding choke-and-kill lines) attached to the outside of the riser main tube

EXAMPLE Hydraulic supply line, buoyancy-control line, mud-boost line.

3.7

ball joint

ball-and-socket assembly having a central through passage that has an internal diameter equal to or greater

than that of the riser and that may be positioned in the riser string to reduce local bending stresses

3.8

blowout

uncontrolled flow of well fluids from the well bore

3.9

blowout preventer

BOP

device attached immediately above the casing, which can be closed to shut in the well

3.10

blowout preventer

〈annular type〉 remotely controlled device that can form a seal in the annular space around any object in the

well bore or upon itself

NOTE Compression of a reinforced elastomer packing element by hydraulic pressure affects the seal.

3.11

BOP stack

assemblage of well-control equipment, including BOPs, spools, valves, hydraulic connectors and nipples, that

connects to the subsea wellhead

NOTE Common usage of this term sometimes includes the lower marine riser package (LMRP).

3.12

box

female member of a riser coupling, C&K line stab assembly or auxiliary line stab assembly

3.13

buoyancy-control line

auxiliary line dedicated to controlling, charging or discharging air-can buoyancy chambers

3.14

buoyancy modules

devices added to riser joints to reduce their apparent weight, thereby reducing riser top tension requirements

2 © ISO 2009 – All rights reserved

3.15

choke-and-kill lines

C&K lines

kill line

external conduits arranged laterally along the riser pipe and used for circulation of fluids into and out of the

well bore to control well pressure

3.16

control pod

assembly of subsea valves and regulators that, when activated from the surface, directs hydraulic fluid

through special porting to operate BOP equipment

3.17

coupling

mechanical means of joining two sections of riser pipe in an end-to-end engagement

3.18

diverter

device attached to the wellhead or marine riser to close the vertical flow path and direct well flow away from

the drill floor and rig

3.19

drift-off

unplanned lateral move of a dynamically positioned vessel off its intended location relative to the wellhead,

generally caused by loss of either stationkeeping control or propulsion

3.20

drilling fluid

mud

water- or oil-based fluid circulated down the drillpipe into the well and back up to the rig for purposes including

containment of formation pressure, the removal of cuttings, bit lubrication and cooling, treating the wall of the

well and providing a transmission mediu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.