ISO 11425:2018

(Main)Rubber hoses and hose assemblies for automobile power-steering systems — Specification

Rubber hoses and hose assemblies for automobile power-steering systems — Specification

This document specifies requirements for five types of hose and hose assembly used in automobile power-steering systems, the five types differing in their pressure ratings and volumetric expansion. They are for use with fluids in the temperature range −40 °C to +135 °C. This document is based on performance tests. In order to take account of technological developments, no requirements are included for specific materials, detailed construction or manufacturing methods.

Tuyaux et flexibles en caoutchouc pour circuits de direction assistée — Spécifications

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 11425

Second edition

2018-11

Rubber hoses and hose assemblies for

automobile power-steering systems —

Specification

Tuyaux et flexibles en caoutchouc pour circuits de direction

assistée — Spécifications

Reference number

©

ISO 2018

© ISO 2018

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2018 – All rights reserved

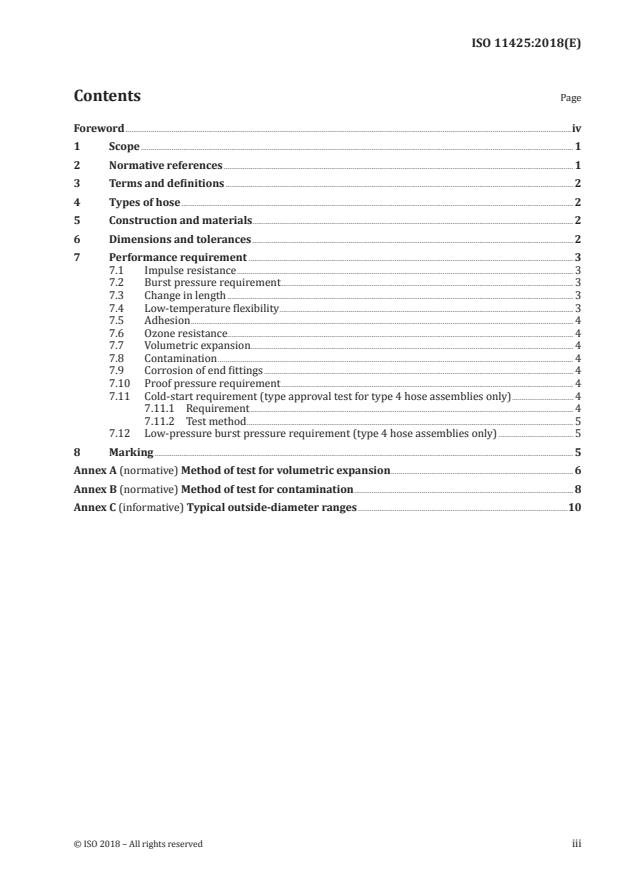

Contents Page

Foreword .iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Types of hose . 2

5 Construction and materials . 2

6 Dimensions and tolerances . 2

7 Performance requirement . 3

7.1 Impulse resistance . 3

7.2 Burst pressure requirement . 3

7.3 Change in length . 3

7.4 Low-temperature flexibility . 3

7.5 Adhesion . 4

7.6 Ozone resistance. 4

7.7 Volumetric expansion. 4

7.8 Contamination . 4

7.9 Corrosion of end fittings . 4

7.10 Proof pressure requirement . 4

7.11 Cold-start requirement (type approval test for type 4 hose assemblies only) . 4

7.11.1 Requirement . 4

7.11.2 Test method . 5

7.12 Low-pressure burst pressure requirement (type 4 hose assemblies only) . 5

8 Marking . 5

Annex A (normative) Method of test for volumetric expansion . 6

Annex B (normative) Method of test for contamination . 8

Annex C (informative) Typical outside-diameter ranges .10

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see www .iso

.org/iso/foreword .html.

This document was prepared by Technical Committee ISO/TC 45, Rubber & Rubber Products,

Subcommittee SC 1, Rubber and plastics hoses and hose assemblies

This second edition cancels and replaces the first edition (ISO 11425:1996), of which it constitutes a

minor revision.

The main changes compared to the previous edition are as follows:

— In Clause 2, normative references have been updated.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/members .html.

iv © ISO 2018 – All rights reserved

INTERNATIONAL STANDARD ISO 11425:2018(E)

Rubber hoses and hose assemblies for automobile power-

steering systems — Specification

WARNING — Attention is drawn to the need to ensure that appropriate precautions are taken to

ensure the safety of personnel carrying out the methods of test specified in this document.

1 Scope

This document specifies requirements for five types of hose and hose assembly used in automobile

power-steering systems, the five types differing in their pressure ratings and volumetric expansion.

They are for use with fluids in the temperature range −40 °C to +135 °C.

This document is based on performance tests. In order to take account of technological developments,

no requirements are included for specific materials, detailed construction or manufacturing methods.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 1402, Rubber and plastics hoses and hose assemblies — Hydrostatic testing

ISO 2719, Determination of flash point — Pensky-Martens closed cup method

ISO 2909, Petroleum products — Calculation of viscosity index from kinematic viscosity

ISO 2977, Petroleum products and hydrocarbon solvents — Determination of aniline point and mixed

aniline point

ISO 3016, Petroleum products — Determination of pour point

ISO 3819, Laboratory glassware — Beakers

ISO 4671, Rubber and plastics hoses and hose assemblies — Methods of measurement of the dimensions of

hoses and the lengths of hose assemblies

ISO 4788, Laboratory glassware — Graduated measuring cylinders

ISO 4793, Laboratory sintered (fritted) filters — Porosity grading, classification and designation

ISO 6803, Rubber or plastics hoses and hose assemblies — Hydraulic-pressure impulse test without flexing

ISO 7326:2016, Rubber and plastics hoses — Assessment of ozone resistance under static conditions

ISO 8033, Rubber and plastics hoses — Determination of adhesion between components

ISO 8330, Rubber and plastics hoses and hose assemblies — Vocabulary

ISO 9227, Corrosion tests in artificial atmospheres — Salt spray tests

ISO 10619-2, Rubber and plastics hoses and tubing — Measurement of flexibility and stiffness — Part 2:

Bending tests at sub-ambient temperatures

ISO/TR 11340:1994, Rubber and rubber products — Hydraulic hose assemblies — External leakage

classification for hydraulic systems

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 8330 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https: //www .iso .org/obp

— IEC Electropedia: available at http: //www .electropedia .org/

3.1

hose assembly

hose with either permanent or re-usable end fittings attached

4 Types of hose

Hoses shall be one of the following five types:

a) Type 1: low-pressure hydraulic fluid return hoses and hose assemblies.

b) Type 2: medium-pressure low volumetric expansion hoses and hose assemblies.

c) Type 3: medium-pressure medium volumetric expansion hoses and hose assemblies.

d) Type 4: medium-pressure high volumetric expansion hoses and hose assemblies.

e) Type 5: high-pressure low volumetric expansion hoses and hose assemblies.

5 Construction and materials

The hose shall consist of:

a) a rubber lining;

b) a reinforcement;

c) a rubber cover or alternatively, for type 5 only, a textile cover.

The hose shall be uniform in quality and free from porosity, air holes and foreign inclusions.

6 Dimensions and tolerances

6.1 The hose shall have a inside diameter in accordance with the requirements of Table 1. When

determined in accordance with ISO 4671, the actual bore shall be within ±0,4 mm of the inside diameter.

Table 1 — Inside diameter

Dimensions in millimetres

Type 1 Type 2 Type 3 Type 4 Type 5

— 6,3 — — —

9,5 9,5 9,5 9,5 9,5

— 12,7 — — 12,7

6.2 The concentricity based on a total indicator reading between the bore and the outside surface of

the cover, determined in accordance with ISO 4671 shall be not more than 0,75 mm.

NOTE Typical ranges of outside diameters available are given in Annex C.

2 © ISO 2018 – All rights reserved

7 Performance requirement

7.1 Impulse resistance

When subjected to a pulse test carried out in accordance with ISO 6803, using the following conditions,

each of at least four test pieces shall withstand a minimum of 225 000 cycles with no more than ISO/

TR 11340:1994 class 3 leakage at fittings, and no rupture or ballooning of the hose.

Test fluid temperature: 135 °C ± 2 °C

Ambient temperature during test: 100 °C ± 5 °C cycle rate: 30 to 40 per min

Cycle data:

Pressure rise time: 0,20 s ± 0,10 s

Pressure dwell time: 0,65 s ± 0,20 s

Pressure drop time: 0,20 s ± 0,10 s

Test pressure: Design working pressure as given in Table 2.

7.2 Burst pressure requirement

When tested in accordance with ISO 1402 the hose or hose assembly shall withstand the minimum

burst pressure given in Table 2.

Table 2 — Hydrostatic-pressure requirements

Inside diameter Design working pressure Proof pressure Minimum burst

pressure

Type

mm MPa MPa MPa

1 9,5 1,75 3,5 7,0

2 6,3 9,0 18,0 36,0

9,5 8,0 16,0 32,0

12,7 7,0 14,0 28,0

3 9,5 10,0 20,0 40,0

4 9,5 9,0 18,0 36,0

5 9,5 15,5 31,0 62,0

12,7 14,0 28,0 56,0

NOTE All pressure values specified are gauge pressures.

7.3 Change in length

Hoses of types 1, 3 and 4 shall not change in length by more than +0 % and –8 % and hoses of types 2

and 5 shall not change in length by more than +2 % and 4 % at the appropriate design working pressure

given in Table 2.

7.4 Low-temperature flexibility

After conditioning at a temperature of –40 °C ± 2 °C for a period of 72 h, bend a test piece around a

mandr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.