ASTM E3121/E3121M-17

(Test Method)Standard Test Methods for Field Testing of Anchors in Concrete or Masonry

Standard Test Methods for Field Testing of Anchors in Concrete or Masonry

SIGNIFICANCE AND USE

4.1 These test methods are intended to provide data from which applicable performance and design data can be determined for a given anchorage device used in a member of concrete, solid, hollow, or grout-filled masonry, and related materials and for qualifying anchors or anchorage systems. Tests performed in the confined condition shall not be used to develop design values. Proof load tests shall not result in damage to properly installed anchors.

4.2 The test methods shall be followed to ensure reproducibility of the test data.

SCOPE

1.1 These test methods cover procedures for static tensile and shear testing of post-installed and cast-in-place anchorage systems in members made of concrete or members made of solid, hollow, or grout-filled masonry and related materials. Tests may be made to determine the ultimate load or to apply a proof load to verify proper installation. Proof load tests performed in the confined condition to verify proper installation shall not be used to develop design values. Only those tests required by the specifying authority need to be performed.

1.2 These test methods are intended for use with such anchorage devices designed to be installed perpendicular to a plane surface of the member.

1.3 Seismic, fatigue, shock, combined tension, and shear and torsion testing are not covered in the methods described herein. If these tests are required, refer to Test Methods E488/E488M for equipment and procedures.

1.4 Both inch-pound and SI units are provided in this standard. The testing may be performed in either system and reported in the system used and converted to the other. However, anchor diameters, threads, and related test equipment shall be in accordance with either inch-pound or SI provisions.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E3121/E3121M − 17

Standard Test Methods for

Field Testing of Anchors in Concrete or Masonry

ThisstandardisissuedunderthefixeddesignationE3121/E3121M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 These test methods cover procedures for static tensile 2.1 ASTM Standards:

and shear testing of post-installed and cast-in-place anchorage E4 Practices for Force Verification of Testing Machines

systems in members made of concrete or members made of E488/E488M Test Methods for Strength of Anchors in

solid, hollow, or grout-filled masonry and related materials. Concrete Elements

Tests may be made to determine the ultimate load or to apply E575 Practice for Reporting Data from Structural Tests of

a proof load to verify proper installation. Proof load tests Building Constructions, Elements, Connections, and As-

performed in the confined condition to verify proper installa- semblies

tionshallnotbeusedtodevelopdesignvalues.Onlythosetests E631 Terminology of Building Constructions

required by the specifying authority need to be performed. E2265 Terminology for Anchors and Fasteners in Concrete

and Masonry

1.2 These test methods are intended for use with such

anchorage devices designed to be installed perpendicular to a

3. Terminology

plane surface of the member.

3.1 For definitions of general terms used in these test

1.3 Seismic, fatigue, shock, combined tension, and shear

methods related to building construction, refer to Terminology

and torsion testing are not covered in the methods described

E631, and for definitions of terms related to anchoring, refer to

herein. If these tests are required, refer to Test Methods

Terminology E2265.

E488/E488M for equipment and procedures.

3.2 Definitions of Terms Specific to This Standard:

1.4 Both inch-pound and SI units are provided in this

3.2.1 cast-in-place anchor, n—an anchor that is installed

standard. The testing may be performed in either system and

prior to the placement of base material and that derives its

reported in the system used and converted to the other.

holding power from plates, lugs, or other protrusions.

However,anchordiameters,threads,andrelatedtestequipment

3.2.1.1 Discussion—Examples include, headed anchor

shall be in accordance with either inch-pound or SI provisions.

bolts, specialty inserts, anchor channels, metal straps, and

1.5 This standard does not purport to address all of the similar embedded items.

safety concerns, if any, associated with its use. It is the

3.2.2 confined test condition, n—test configuration in which

responsibility of the user of this standard to establish appro-

the reaction forces from the test equipment are transferred to

priate safety, health, and environmental practices and deter-

the member surface in close proximity to the anchor element.

mine the applicability of regulatory limitations prior to use.

3.2.3 Manufacturer’s Printed Installation Instructions

1.6 This international standard was developed in accor-

(MPII), n—instructions for correct anchor installation under all

dance with internationally recognized principles on standard-

covered installation conditions as approved and supplied in

ization established in the Decision on Principles for the

product packaging by the manufacturer of the anchor system.

Development of International Standards, Guides and Recom-

3.2.4 member, n—the base material in which the anchor is

mendations issued by the World Trade Organization Technical

installed and which resists forces from the anchor.

Barriers to Trade (TBT) Committee.

3.2.5 post-installed anchor, n—an anchor that is installed

after the placement and hardening of base material.

These test methods are under the jurisdiction of ASTM Committee E06 on

Performance of Buildings and is the direct responsibility of Subcommittee E06.13 For referenced ASTM standards, visit the ASTM website, www.astm.org, or

on Structural Performance of Connections in Building Construction. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Sept. 1, 2017. Published December 2017. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/E3121_E3121M-17. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E3121/E3121M − 17

3.2.5.1 Discussion—Examples include, expansion, number of data points recorded shall be selected based on the

undercut, screw, grouted, and adhesive anchors. expected ultimate capacity of the anchor and shall be sufficient

to accurately show the load-displacement behavior. The test

3.2.6 proof load, n—a test load applied to an anchor for a

fixture(s) shall be of sufficient capacity to prevent yielding of

specified duration, if applicable, to verify proper installation.

itsvariouscomponentsandshallensurethattheappliedtension

3.2.7 unconfined test condition, n—test configuration in

loads remain parallel to and centered on the anchors and that

which the reactions from the test equipment are spaced a

the applied shear loads remain parallel to the surface of the

suitable distance from the anchor to allow unrestricted devel-

member during testing.

opment of a conical fracture surface.

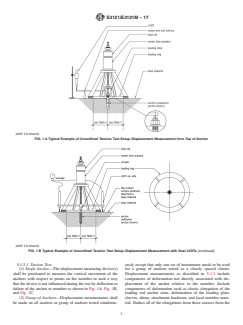

5.1.1 Tension Test—An example of a typical system for

3.3 Symbols:

applying tension pull-out forces to a single anchor is shown in

3.3.1 c—edge distance, measured from centerline of anchor

Fig. 1A, Fig. 1B, and Fig. 1C. The test system support(s) shall

to edge of member or test frame support, in. [mm].

be of sufficient size to prevent local crushing or failure of the

3.3.2 d—nominal anchor diameter, in. [mm].

surrounding member. Tests may be performed as confined or

unconfined (see 6.3 and definitions) as specified. The loading

3.3.3 d —diameter of drilled borehole in member, in.

hole

rod shall be of sufficient size and strength to develop the

[mm].

ultimate strength of the anchor at a stress level less than its

3.3.4 d —diameter of hole in confining plate for con-

opening

yieldstrength.AloadingshoemaybeusedasshowninFig.1A

fined tension tests, in. [mm].

or the loading rod may be directly coupled to the anchor as

3.3.5 F—maximum test load, lbf [kN].

shown in Fig. 1B. If a loading shoe is used, it should be of

3.3.6 h—thickness of the member, in. [mm].

sufficient thickness to prevent yielding during loading. The

thickness should be at least equal to the nominal size of the

3.3.7 h —effective depth of embedment of an anchor, in.

ef

anchor. Appropriate linkages or fixtures, such as ball and

[mm].

socket spherical device, shall be included in the load path to

3.3.8 n—number of test specimens.

minimize the direct transfer of bending stress to the anchor due

3.3.9 s—anchor spacing measured centerline to centerline,

to misalignment of the loading system. For confined tests, a

in. [mm].

sheet of tetrafluoroethylene (TFE), polytetrafluoroethylene

3.3.10 t —thickness of confining plate for tension tests,≥d,

pl (PTFE), fluorinated ethylene propylene (FEP), or perfluoro-

in. [mm].

alkoxy (PFA) of 0.020 6 0.004 in. [0.5 6 0.1 mm] thickness

shall be placed between the loading plate and the surface of the

4. Significance and Use

member.

4.1 These test methods are intended to provide data from

5.1.2 Shear Test—An example of a typical system for

which applicable performance and design data can be deter-

applying shear force to a single anchor is shown in Fig. 2. The

mined for a given anchorage device used in a member of

thicknessoftheshearloadingplateintheimmediatevicinityof

concrete, solid, hollow, or grout-filled masonry, and related

the test anchor shall be equal to the nominal bolt diameter to be

materials and for qualifying anchors or anchorage systems.

tested unless another diameter is specified, with a tolerance of

Tests performed in the confined condition shall not be used to

1 1

– ⁄16 in., + ⁄8 in. [–1.5 mm, + 3.0 mm]. The edges of the shear

develop design values. Proof load tests shall not result in

loading plate shall be chamfered or have a radius to prevent

damage to properly installed anchors.

digging into the surface of the member. The hole in the shear

4.2 The test methods shall be followed to ensure reproduc- loading plate shall have a diameter 0.06 in. 6 0.03 in. [1.5 mm

6 0.75 mm] greater than the test anchor. The initial shape of

ibility of the test data.

the hole in the shear loading plate shall correspond to that of

5. Apparatus

the anchor cross section and shall be maintained throughout all

tests. Worn or deformed holes shall be repaired. Hardened

5.1 Equipment—Calibrated electronic load cells or hydrau-

insert sleeves of the required diameter may be periodically

lic ram and pressure gauge systems calibrated together as a

installed in the shear loading plate to meet these requirements.

system shall be used. This equipment shall be capable of

A sheet of tetrafluoroethylene (TFE), polytetrafluoroethylene

measuring the forces to an accuracy within 62 % of the

(PTFE), fluorinated ethylene propylene (FEP), or perfluoro-

calibrated capacity, when calibrated in accordance with Prac-

alkoxy (PFA) of 0.020 6 0.004 in. [0.5 6 0.1 mm] thickness

tices E4. For tests which require displacement measurements,

and corresponding to the area required according to Table 1

useeithermanuallyreaddialgaugesorelectronicdisplacement

shall be placed between the shear loading plate and the surface

measuring devices with accuracy of 60.001 in. [0.025 mm].

of the member.

The instrument(s) shall be positioned to measure movement of

the anchor in the direction of the applied load in such a way 5.1.3 Anchor Displacement Measurement—For anchor tests

that the instrument is not influenced during the test by that require displacement measurements, the displacement

movement or failure of the anchor or member. If load and measurements shall be made using LVDT device(s), dial

corresponding displacement measurements are required, the gauges, or equivalent.

E3121/E3121M − 17

(NOT TO SCALE)

FIG. 1 A Typical Example of Unconfined Tension Test Setup–Displacement Measurement from Top of Anchor

(NOT TO SCALE)

FIG. 1 B Typical Example of Unconfined Tension Test Setup–Displacement Measurement with Dual LVDTs (continued)

5.1.3.1 Tension Test: ously except that only one set of instruments needs to be used

(1) Single Anchor—The displacement measuring device(s) for a group of anchors tested as a closely spaced cluster.

shall be positioned to measure the vertical movement of the Displacement measurements as described in 5.1.3 include

anchors with respect to points on the member in such a way components of deformation not directly associated with dis-

that the device is not influenced during the test by deflection or placement of the anchor relative to the member. Include

failure of the anchor or member as shown in Fig. 1A, Fig. 1B, components of deformation such as elastic elongation of the

and Fig. 1C. loading rod anchor stem, deformation of the loading plate,

(2) Group of Anchors—Displacement measurements shall sleeves, shims, attachment hardware, and local member mate-

be made on all anchors or group of anchors tested simultane- rial. Deduct all of the elongations from these sources from the

E3121/E3121M − 17

(NOT TO SCALE)

FIG. 1 C Typical Example of Confined Tension Test Setup–Adhesive Anchor Shown (continued)

FIG. 2 Method of Applying Shear Loads to Anchors Attached to Members

TABLE 1 Shear Loading Plate Bearing Area as Function of

The displacement to be used for the evaluation of the findings

Anchor Diameter

is the average displacement indicated by both instruments

A

Anchor Diameter Shear Loading Plate Contact Area,

mounted symmetrically equidistant from the centroid of the

2 2

in. [cm ]

in. [mm]

cluster as shown in Fig. 3.

< ⁄8 [<10] 8 [50]

3 5

⁄8# ⁄8 [10# 16] 12 [80] 5.1.3.2 Shear Test—The displacement measuring device(s)

5 7

⁄8# ⁄8 [16# 22] 18 [120]

shall be positioned to measure displacement in the direction of

⁄8#2[22# 51] 25 [160]

the applied load. The device shall be placed on the member to

>2 [>51] 40 [260]

A allow the sensing element to bear perpendicularly on the

Shear loading plate contact area with PTFE or other friction-limiting material.

anchor or on a contact plate located on the shear loading plate

as shown in Fig. 2 or other method that prevents extraneous

deflections. For tests on clusters of anchors, the instrument

totaldisplacementmeasurementsbyusingsupplementarymea-

suring devices or calibration test data for the installed test shall lie on a plane through the axis of the shear loading rod or

set-up with rigid specimen replacing the anchor to be tested. plate.An extension of the axis of the shear loading rod or plate

E3121/E3121M − 17

FIG. 3 Typical Method of Applying Test Load to Cluster of Anchors in Test Area of Member

shall pass through the geometric centroid of the cluster of 6.4.2 Members Fabricated Specifically for Testing—The

anchors assuming anchors are the same size. member shall be representative of the materials and configu-

ration intended for field use. The member is not prohibited

6. Test Specimens

from being steel-reinforced. The location and orientation of

any reinforcement embedded in concrete or masonry members

6.1 Anchorage System—If not already installed, the anchor-

shall be reported. The depth of the member shall be at least

age system shall be representative of the type to be used in

1.5 h in thickness so long as the depth is suitable for normal

ef

construction and shall include all accessory hardware normally

installation of the anchor and does not result in premature

required for its use, that is, all attachment hardware.

failure of either the member or anchor, unless the specific test

6.2 Anchor Installation—If not already installed, the an-

application requires a lesser thickness. The member will act as

chorage device shall be installed in accordance with the

a beam if the spacing between reaction supports is greater than

Manufacturer’s Printed Installation Instructions (MPII), or,

the thickness of the member. A member with a thickness of at

where specific deviation is justified, in accordance with good

least 1.5 h will minimize bending during the application of

ef

field methods.

the tensile load

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.