ASTM D7954/D7954M-22a

(Practice)Standard Practice for Moisture Surveying of Roofing and Waterproofing Systems Using Nondestructive Electrical Impedance Scanners

Standard Practice for Moisture Surveying of Roofing and Waterproofing Systems Using Nondestructive Electrical Impedance Scanners

SIGNIFICANCE AND USE

5.1 Excess moisture trapped in roofing or waterproofing systems can adversely affect performance and lead to premature failure of roofing or waterproofing systems and its components. It also reduces thermal resistance, resulting in reduced energy efficiency and inflated energy costs. Impedance scans can be effective in identifying concealed and entrapped moisture within roofing or waterproofing systems.

5.2 This practice is intended to be used at various stages of the roofing and waterproofing system’s life such as: during or at completion of installation of roofing or waterproofing system to determine if there was moisture intrusion into the roofing or waterproofing system or underlying materials; at regular intervals as part of a preventative maintenance program; and to aid in condition assessment, or before replacement or repair work, or combinations thereof, to assist in determining the extent of work and replacement materials.

5.3 This practice alone does not determine the cause of moisture infiltration into roofing or waterproofing systems; however, it can be used to help tracing excess moisture to the point of ingress.

SCOPE

1.1 This practice applies to techniques that use nondestructive electrical impedance (EI) scanners to locate moisture and evaluate the comparative moisture content within insulated low-slope roofing and waterproofing systems.

1.2 This practice is applicable to roofing and waterproofing systems wherein insulation is placed above the deck and positioned underneath and in contact with electrically nonconductive single-ply or built-up roofing and waterproofing membranes and systems such as coal tar, asphalt, modified bitumen, thermoplastics, spray polyurethane foam, and similar electrically nonconductive membrane materials. This practice is also applicable to roofing and waterproofing systems without insulation placed above moisture absorbing decks such as wood, concrete, or gypsum, that are in contact with single-ply or built-up roofing and waterproofing membranes as described above.

1.3 This practice is applicable to roofing and waterproofing systems incorporating electrically nonconductive rigid board insulation made from materials such as organic fibers, perlite, cork, fiberglass, wood-fiber, polyisocyanurate, polystyrene, phenolic foam, composite boards, gypsum substrate boards, and other electrically nonconductive roofing and waterproofing systems such as spray-applied polyurethane foam.

1.4 This practice is not appropriate for all combinations of materials used in roofing and waterproofing systems.

1.4.1 Metal and other electrically conductive surface coverings and near-surface embedded metallic components are not suitable for surveying with impedance scanners because of the electrical conductivity of these materials.

1.4.2 This practice is not appropriate for use with black EPDM, any membranes containing black EPDM, or black EPDM coatings because black EPDM gives false positive readings.

1.4.3 Aluminum foil on top-faced insulation, roofing, or waterproofing membranes gives a false positive reading and is not suitable for surveying with impedance scanners; however, liquid-applied aluminum pigmented emulsified asphalt-based coatings shall not normally affect impedance scanner readings.

1.4.3.1 This practice is not appropriate for use with aluminium foil faced modified bitumen membranes, as the electrical conductivity of the aluminium foil surface can give false positive readings.

1.4.4 While their overburden remains in place, this practice is not appropriate for use with inverted roof membrane assemblies (IRMAs) or protected roof assemblies (PRMAs), which contain above the deck waterproof membrane and overburden that may include insulation, drainage components, pavers, aggregate, ballast, vegetation, or combinations thereof, because the impedance scanner will not differentiate between above and below the membrane moisture.

1.4.5 S...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D7954/D7954M −22a

Standard Practice for

Moisture Surveying of Roofing and Waterproofing Systems

Using Nondestructive Electrical Impedance Scanners

This standard is issued under the fixed designation D7954/D7954M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.4.3 Aluminum foil on top-faced insulation, roofing, or

waterproofing membranes gives a false positive reading and is

1.1 This practice applies to techniques that use nondestruc-

not suitable for surveying with impedance scanners; however,

tive electrical impedance (EI) scanners to locate moisture and

liquid-applied aluminum pigmented emulsified asphalt-based

evaluate the comparative moisture content within insulated

coatings shall not normally affect impedance scanner readings.

low-slope roofing and waterproofing systems.

1.4.3.1 This practice is not appropriate for use with alu-

1.2 This practice is applicable to roofing and waterproofing

minium foil faced modified bitumen membranes, as the elec-

systems wherein insulation is placed above the deck and

trical conductivity of the aluminium foil surface can give false

positioned underneath and in contact with electrically noncon-

positive readings.

ductive single-ply or built-up roofing and waterproofing mem-

1.4.4 While their overburden remains in place, this practice

branes and systems such as coal tar, asphalt, modified bitumen,

is not appropriate for use with inverted roof membrane

thermoplastics, spray polyurethane foam, and similar electri-

assemblies (IRMAs) or protected roof assemblies (PRMAs),

cally nonconductive membrane materials. This practice is also

which contain above the deck waterproof membrane and

applicable to roofing and waterproofing systems without insu-

overburden that may include insulation, drainage components,

lation placed above moisture absorbing decks such as wood,

pavers, aggregate, ballast, vegetation, or combinations thereof,

concrete, or gypsum, that are in contact with single-ply or

because the impedance scanner will not differentiate between

built-up roofing and waterproofing membranes as described

above and below the membrane moisture.

above.

1.4.5 SeeA1.4forsomecautionarynotesonroofinganoma-

1.3 This practice is applicable to roofing and waterproofing

lies and limitations that affect the impedance test practice.

systems incorporating electrically nonconductive rigid board

1.5 Moisture scanners using impedance-based technology

insulation made from materials such as organic fibers, perlite,

are classified as EI scanners.

cork, fiberglass, wood-fiber, polyisocyanurate, polystyrene,

phenolic foam, composite boards, gypsum substrate boards,

NOTE 1—The term capacitance is sometimes used when describing

andotherelectricallynonconductiveroofingandwaterproofing

impedance scanners. Capacitance scanners are purely capacitive as they

systems such as spray-applied polyurethane foam. do not have a resistive component. Impedance scanners combine both

capacitance and resistance for testing; thus, they are well suited to the

1.4 This practice is not appropriate for all combinations of

measurement of different types of materials and constructions found in

materials used in roofing and waterproofing systems. roofingandwaterproofingsystemsasthecombinationofbothcomponents

allows for a more versatile testing, calibration, and measurement arrange-

1.4.1 Metal and other electrically conductive surface cover-

ment.

ings and near-surface embedded metallic components are not

suitable for surveying with impedance scanners because of the 1.6 This practice also addresses necessary verification of

electrical conductivity of these materials.

impedance data involving invasive test procedures using core

1.4.2 This practice is not appropriate for use with black samples.

EPDM, any membranes containing black EPDM, or black

1.7 This practice addresses two generally accepted scanning

EPDM coatings because black EPDM gives false positive

techniques for conducting moisture surveys using electrical

readings.

impedance scanners:

1.7.1 Technique A—Continuous systematic scanning and

recording (see 8.2), and

ThispracticeisunderthejurisdictionofASTMCommitteeD08onRoofingand

1.7.2 Technique B—Grid format scanning and recording

Waterproofing and is the direct responsibility of Subcommittee D08.20 on Roofing

(see 8.3).

Membrane Systems.

Current edition approved May 1, 2022. Published May 2022. Originally

1.8 This practice addresses some meteorological conditions

approved in 2014. Last previous edition approved in 2022 as D7954/D7954M – 22.

DOI: 10.1520/D7954_D7954M-22A. and limitations for performing impedance inspections.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7954/D7954M−22a

1.9 This practice addresses the effect of the roofing or obtained by cutting through these components down to the

waterproofing construction, material differences, and exterior deck and removing them from the roofing section under test.

surface conditions on the moisture inspections.

3.2.2.1 Discussion—Core samples are used to verify the

membrane and insulation composition and ascertain informa-

1.10 This practice addresses operating procedures, operator

tion on their condition.

qualifications, operating methods, scanning, surveying, and

recording techniques. 3.2.3 detect or detection, v or n—for the purpose of imped-

ance scanning, the condition at which there is a consistent

1.11 Units—The values stated in either SI units or inch-

indication that an elevated level of impedance reading is

pound units are to be regarded separately as standard. The

present within the roofing or waterproofing system.

values stated in each system may not be exact equivalents;

therefore,eachsystemshallbeusedindependentlyoftheother. 3.2.4 false-positive, adj—readingthatindicatesthatelevated

Combining values from the two systems may result in noncon- moisture is present when it is not.

formance with the standard. 3.2.4.1 Discussion—For example, a false positive in roofing

for impedance scanning may be returned when some other

1.12 This standard does not purport to address all of the

electrically conductive material is present in the roofing

safety concerns, if any, associated with its use. It is the

system.

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

3.2.5 gravimetric analysis, n—determination of moisture

mine the applicability of regulatory limitations prior to use.

content by weight of a material by comparing wet weight to

Caution should be taken when accessing, walking, or using

oven dry weight expressed as a percentage.

scanning equipment on the roofing or waterproofing surfaces,

3.2.6 moisture content, MC, n—mass of moisture per unit

or elevated locations, when using ladders, and when raising

mass of dry material.

and lowering equipment to elevated locations.

3.2.6.1 Discussion—The moisture content is usually ex-

1.13 This international standard was developed in accor-

pressed as a percentage by weight and determined gravimetri-

dance with internationally recognized principles on standard-

cally.

ization established in the Decision on Principles for the

3.2.7 roof assembly, n—assembly of interacting roof com-

Development of International Standards, Guides and Recom-

ponents including the roof deck, air or vapor retarder, insula-

mendations issued by the World Trade Organization Technical

tion and membrane, or primary roof covering designed to

Barriers to Trade (TBT) Committee.

weatherproof a structure.

2. Referenced Documents

3.2.8 roof section, n—portion of a roof that is separated

from adjacent portions by walls or expansion joints with no

2.1 ASTM Standards:

changes in the components throughout the section.

C1616 Test Method for Determining the Moisture Content

of Organic and Inorganic Insulation Materials by Weight

4. Summary of Practice

D1079 Terminology Relating to Roofing and Waterproofing

D7438 Practice for Field Calibration and Application of

4.1 This practice covers a procedure in which a specifically

Hand-Held Moisture Meters

developed nondestructive electronic impedance (EI) based

E2586 Practice for Calculating and Using Basic Statistics

moisture scanner is used in conjunction with interpretive data

F2659 Guide for Preliminary Evaluation of Comparative

and invasive verification practices to detect and evaluate the

Moisture Condition of Concrete, Gypsum Cement and

moisture conditions within low-sloped roofing and waterproof-

Other Floor Slabs and Screeds Using a Non-Destructive

ing systems by nondestructively measuring the electrical alter-

Electronic Moisture Meter

nating current (ac) impedance.

NOTE 2—See A1.3 for other referenced documents.

4.2 This practice is intended to be used in conjunction with

the impedance scanner manufacturer’s operation instructions

3. Terminology

and guides.

3.1 For definitions of terms used in this practice, refer to

Terminology D1079.

5. Significance and Use

3.2 Definitions of Terms Specific to This Standard:

5.1 Excess moisture trapped in roofing or waterproofing

3.2.1 comparative moisture, content, n—qualitative charac-

systems can adversely affect performance and lead to prema-

terization of moisture content in relative terms (that is, low,

ture failure of roofing or waterproofing systems and its

medium, and high levels of moisture).

components. It also reduces thermal resistance, resulting in

reduced energy efficiency and inflated energy costs. Impedance

3.2.2 core sample, n—small specimen of insulation and

membrane having a minimum of 2 in. [50 mm] diameter scans can be effective in identifying concealed and entrapped

moisture within roofing or waterproofing systems.

5.2 This practice is intended to be used at various stages of

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

the roofing and waterproofing system’s life such as: during or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

atcompletionofinstallationofroofingorwaterproofingsystem

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. to determine if there was moisture intrusion into the roofing or

D7954/D7954M−22a

waterproofing system or underlying materials; at regular inter- well as the composition of materials, thickness, and moisture

vals as part of a preventative maintenance program; and to aid content of the roofing or waterproofing system under test.

in condition assessment, or before replacement or repair work, 6.1.2 Apparatus Requirements:

or combinations thereof, to assist in determining the extent of 6.1.2.1 The moisture scanner shall be capable of sending

work and replacement materials. signals nondestructively into the materials below the surfacing

and the scanner.

5.3 This practice alone does not determine the cause of

6.1.2.2 The moisture scanner shall have integrated adjust-

moisture infiltration into roofing or waterproofing systems;

able calibration ability for the differing composition, thickness,

however, it can be used to help tracing excess moisture to the

density of materials, and moisture conditions that can be

point of ingress.

encountered in roofing or waterproofing assemblies.

6.1.2.3 The moisture scanner shall have a display giving

6. Apparatus

comparativereadingsofmoistureconditionsofmaterialsfound

6.1 EI Scanner—This apparatus shall be specifically devel-

in roofing and waterproofing systems.

oped to detect and evaluate nondestructively comparative

6.2 Scanner Types—Two types of impedance scanners are

moisture conditions within roofing and waterproofing systems.

commercially available:

6.1.1 Principles of Operation—The EI of a material varies

6.2.1 Handheld scanner designed to be used for point

in proportion with the material’s moisture content. The EI of

readings on a grid system, and

materials such as those listed in 1.2 and 1.3 in the roofing or

6.2.2 Mobile-wheeled scanner, which can be rolled across

waterproofing system directly under the footprint of the scan-

the roofing or waterproofing to obtain continuous readings as

ner is measured by creating an alternating electric field that

the scanner moves over the surface.

penetrates the materials under test. The small alternating

current (ac) flowing through this field is inversely proportional

NOTE 3—See A1.1 and A1.2 for examples of typical handheld and

with the impedance of these moisture-absorbing materials.The mobile-wheeled types of impedance scanners.

instrumentdeterminesthecurrent’samplitudeandconvertsthis

7. Operator Qualifications and Referenced Materials

value to a comparative moisture value.

6.1.1.1 The depth of the signal penetration varies depending 7.1 The operator shall:

on the sensitivity and signal strength settings of the scanner as 7.1.1 Be familiar with the use of the impedance scanner;

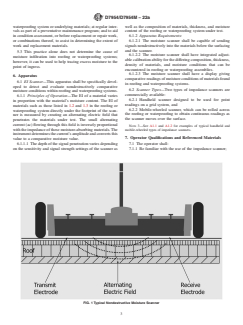

FIG. 1Typical Nondestructive Moisture Scanner

D7954/D7954M−22a

7.1.2 Have knowledge of and available for reference at the grid pattern. Readings are taken and recorded at each grid

roof site a copy of the manufacturer’s operating and calibration intersection point or at regular similar spaced intervals on or

instructions for the impedance scanner used; between grid lines; additional readings are taken and recorded

7.1.3 Have knowledge of how and under what circum- in areas where elevated moisture levels are indicated by

stances the impedance scanning system can be used, as well as increased impedance readings.

its limitations;

8.3.2 See 9.3 for information on grid system layout.

7.1.4 Have a thorough understanding of the construction

8.3.3 This technique is considered applicable to both hand-

and components used in the roofing or waterproofing system

heldandthemobile-wheeledimpedancescannersasreferenced

assembly under test, such as types of membranes, roofing

in 6.2.1 and 6.2.2.

insulations, decking, and attachment;

8.4 When impedance or comparative moisture level read-

7.1.5 Confirm the composition of the roofing or waterproof-

ings or other markings are recorded on the roof surface, obtain

ing assembly and endeavor to obtain historical data regarding

permission from the building owners or their agent before

the construction, age, and performance of the roofing or

marking the roof surface with paint or similar marking mate-

waterproofing assembly

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7954/D7954M − 22 D7954/D7954M − 22a

Standard Practice for

Moisture Surveying of Roofing and Waterproofing Systems

Using Nondestructive Electrical Impedance Scanners

This standard is issued under the fixed designation D7954/D7954M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice applies to techniques that use nondestructive electrical impedance (EI) scanners to locate moisture and evaluate

the comparative moisture content within insulated low-slope roofing and waterproofing systems.

1.2 This practice is applicable to roofing and waterproofing systems wherein insulation is placed above the deck and positioned

underneath and in contact with electrically nonconductive single-ply or built-up roofing and waterproofing membranes and systems

such as coal tar, asphalt, modified bitumen, thermoplastics, spray polyurethane foam, and similar electrically nonconductive

membrane materials. This practice is also applicable to roofing and waterproofing systems without insulation placed above

moisture absorbing decks such as wood, concrete, or gypsum, that are in contact with single-ply or built-up roofing and

waterproofing membranes as described above.

1.3 This practice is applicable to roofing and waterproofing systems incorporating electrically nonconductive rigid board

insulation made from materials such as organic fibers, perlite, cork, fiberglass, wood-fiber, polyisocyanurate, polystyrene, phenolic

foam, composite boards, gypsum substrate boards, and other electrically nonconductive roofing and waterproofing systems such

as spray-applied polyurethane foam.

1.4 This practice is not appropriate for all combinations of materials used in roofing and waterproofing systems.

1.4.1 Metal and other electrically conductive surface coverings and near-surface embedded metallic components are not suitable

for surveying with impedance scanners because of the electrical conductivity of these materials.

1.4.2 This practice is not appropriate for use with black EPDM, any membranes containing black EPDM, or black EPDM coatings

because black EPDM gives false positive readings.

1.4.3 Aluminum foil on top-faced insulation, roofing, or waterproofing membranes gives a false positive reading and is not

suitable for surveying with impedance scanners; however, liquid-applied aluminum pigmented emulsified asphalt-based coatings

shall not normally affect impedance scanner readings.

1.4.3.1 This practice is not appropriate for use with aluminium foil faced modified bitumen membranes, as the electrical

conductivity of the aluminium foil surface can give false positive readings.

1.4.4 While their overburden remains in place, this practice is not appropriate for use with inverted roof membrane assemblies

This practice is under the jurisdiction of ASTM Committee D08 on Roofing and Waterproofing and is the direct responsibility of Subcommittee D08.20 on Roofing

Membrane Systems.

Current edition approved April 15, 2022May 1, 2022. Published May 2022. Originally approved in 2014. Last previous edition approved in 20212022 as

D7954/D7954M – 15a (2021).D7954/D7954M – 22. DOI: 10.1520/D7954_D7954M-22.10.1520/D7954_D7954M-22A.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7954/D7954M − 22a

(IRMAs) or protected roof assemblies (PRMAs), which contain above the deck waterproof membrane and overburden that may

include insulation, drainage components, pavers, aggregate, ballast, vegetation, or combinations thereof, because the impedance

scanner will not differentiate between above and below the membrane moisture.

1.4.5 See A1.4 for some cautionary notes on roofing anomalies and limitations that affect the impedance test practice.

1.5 Moisture scanners using impedance-based technology are classified as EI scanners.

NOTE 1—The term capacitance is sometimes used when describing impedance scanners. Capacitance scanners are purely capacitive as they do not have

a resistive component. Impedance scanners combine both capacitance and resistance for testing; thus, they are well suited to the measurement of different

types of materials and constructions found in roofing and waterproofing systems as the combination of both components allows for a more versatile

testing, calibration, and measurement arrangement.

1.6 This practice also addresses necessary verification of impedance data involving invasive test procedures using core samples.

1.7 This practice addresses two generally accepted scanning techniques for conducting moisture surveys using electrical

impedance scanners:

1.7.1 Technique A—Continuous systematic scanning and recording (see 8.2), and

1.7.2 Technique B—Grid format scanning and recording (see 8.3).

1.8 This practice addresses some meteorological conditions and limitations for performing impedance inspections.

1.9 This practice addresses the effect of the roofing or waterproofing construction, material differences, and exterior surface

conditions on the moisture inspections.

1.10 This practice addresses operating procedures, operator qualifications, operating methods, scanning, surveying, and recording

techniques.

1.11 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated

in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values

from the two systems may result in nonconformance with the standard.

1.12 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use. Caution should be taken when accessing, walking, or using scanning equipment on the roofing

or waterproofing surfaces, or elevated locations, when using ladders, and when raising and lowering equipment to elevated

locations.

1.13 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

C1616 Test Method for Determining the Moisture Content of Organic and Inorganic Insulation Materials by Weight

D1079 Terminology Relating to Roofing and Waterproofing

D7438 Practice for Field Calibration and Application of Hand-Held Moisture Meters

E2586 Practice for Calculating and Using Basic Statistics

F2659 Guide for Preliminary Evaluation of Comparative Moisture Condition of Concrete, Gypsum Cement and Other Floor

Slabs and Screeds Using a Non-Destructive Electronic Moisture Meter

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

D7954/D7954M − 22a

NOTE 2—See A1.3 for other referenced documents.

3. Terminology

3.1 For definitions of terms used in this practice, refer to Terminology D1079.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 comparative moisture, content, n—qualitative characterization of moisture content in relative terms (that is, low, medium,

and high levels of moisture).

3.2.2 core sample, n—small specimen of insulation and membrane having a minimum of 2 in. [50 mm] diameter obtained by

cutting through these components down to the deck and removing them from the roofing section under test.

3.2.2.1 Discussion—

Core samples are used to verify the membrane and insulation composition and ascertain information on their condition.

3.2.3 detect or detection, v or n—for the purpose of impedance scanning, the condition at which there is a consistent indication

that an elevated level of impedance reading is present within the roofing or waterproofing system.

3.2.4 false-positive, adj—reading that indicates that elevated moisture is present when it is not.

3.2.4.1 Discussion—

For example, a false positive in roofing for impedance scanning may be returned when some other electrically conductive material

is present in the roofing system.

3.2.5 gravimetric analysis, n—determination of moisture content by weight of a material by comparing wet weight to oven dry

weight expressed as a percentage.

3.2.6 moisture content, MC, n—mass of moisture per unit mass of dry material.

3.2.6.1 Discussion—

The moisture content is usually expressed as a percentage by weight and determined gravimetrically.

3.2.7 roof assembly, n—assembly of interacting roof components including the roof deck, air or vapor retarder, insulation and

membrane, or primary roof covering designed to weatherproof a structure.

3.2.8 roof section, n—portion of a roof that is separated from adjacent portions by walls or expansion joints with no changes in

the components throughout the section.

4. Summary of Practice

4.1 This practice covers a procedure in which a specifically developed nondestructive electronic impedance (EI) based moisture

scanner is used in conjunction with interpretive data and invasive verification practices to detect and evaluate the moisture

conditions within low-sloped roofing and waterproofing systems by nondestructively measuring the electrical alternating current

(ac) impedance.

4.2 This practice is intended to be used in conjunction with the impedance scanner manufacturer’s operation instructions and

guides.

5. Significance and Use

5.1 Excess moisture trapped in roofing or waterproofing systems can adversely affect performance and lead to premature failure

of roofing or waterproofing systems and its components. It also reduces thermal resistance, resulting in reduced energy efficiency

and inflated energy costs. Impedance scans can be effective in identifying concealed and entrapped moisture within roofing or

waterproofing systems.

5.2 This practice is intended to be used at various stages of the roofing and waterproofing system’s life such as: during or at

completion of installation of roofing or waterproofing system to determine if there was moisture intrusion into the roofing or

D7954/D7954M − 22a

waterproofing system or underlying materials; at regular intervals as part of a preventative maintenance program; and to aid in

condition assessment, or before replacement or repair work, or combinations thereof, to assist in determining the extent of work

and replacement materials.

5.3 This practice alone does not determine the cause of moisture infiltration into roofing or waterproofing systems; however, it can

be used to help tracing excess moisture to the point of ingress.

6. Apparatus

6.1 EI Scanner—This apparatus shall be specifically developed to detect and evaluate nondestructively comparative moisture

conditions within roofing and waterproofing systems.

6.1.1 Principles of Operation—The EI of a material varies in proportion with the material’s moisture content. The EI of materials

such as those listed in 1.2 and 1.3 in the roofing or waterproofing system directly under the footprint of the scanner is measured

by creating an alternating electric field that penetrates the materials under test. The small alternating current (ac) flowing through

this field is inversely proportional with the impedance of these moisture-absorbing materials. The instrument determines the

current’s amplitude and converts this value to a comparative moisture value.

6.1.1.1 The depth of the signal penetration varies depending on the sensitivity and signal strength settings of the scanner as well

as the composition of materials, thickness, and moisture content of the roofing or waterproofing system under test.

6.1.2 Apparatus Requirements:

6.1.2.1 The moisture scanner shall be capable of sending signals nondestructively into the materials below the surfacing and the

scanner.

FIG. 1 Typical Nondestructive Moisture Scanner

D7954/D7954M − 22a

6.1.2.2 The moisture scanner shall have integrated adjustable calibration ability for the differing composition, thickness, density

of materials, and moisture conditions that can be encountered in roofing or waterproofing assemblies.

6.1.2.3 The moisture scanner shall have a display giving comparative readings of moisture conditions of materials found in roofing

and waterproofing systems.

6.2 Scanner Types—Two types of impedance scanners are commercially available:

6.2.1 Handheld scanner designed to be used for point readings on a grid system, and

6.2.2 Mobile-wheeled scanner, which can be rolled across the roofing or waterproofing to obtain continuous readings as the

scanner moves over the surface.

NOTE 3—See A1.1 and A1.2 for examples of typical handheld and mobile-wheeled types of impedance scanners.

7. Operator Qualifications and Referenced Materials

7.1 The operator shall:

7.1.1 Be familiar with the use of the impedance scanner;

7.1.2 Have knowledge of and available for reference at the roof site a copy of the manufacturer’s operating and calibration

instructions for the impedance scanner used;

7.1.3 Have knowledge of how and under what circumstances the impedance scanning system can be used, as well as its

limitations;

7.1.4 Have a thorough understanding of the construction and components used in the roofing or waterproofing system assembly

under test, such as types of membranes, roofing insulations, decking, and attachment;

7.1.5 Confirm the composition of the roofing or waterproofing assembly and endeavor to obtain historical data regarding the

construction, age, and performance of the roofing or waterproofing assembly; and

7.1.6 Have a thorough understanding and knowledge of roofing and waterproofing technology including types of roofing or

waterproofing membranes and materials, decks, insulation materials, system assemblies and construction procedures, equilibrium

moisture content, moisture migration in buildings, as well as health and safety requirements when carrying out roofing or

waterproofing moisture sur

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.