ISO 5011:2020

(Main)Inlet air cleaning equipment for internal combustion engines and compressors — Performance testing

Inlet air cleaning equipment for internal combustion engines and compressors — Performance testing

This document establishes and specifies uniform test procedures, conditions, equipment and a performance report to permit the direct laboratory performance comparison of air cleaners. The basic performance characteristics of greatest interest are air flow restriction or differential pressure, dust collection efficiency, dust capacity and oil carry-over on oil bath air cleaners. This test code therefore deals with the measurement of these parameters. This document is applicable to air cleaners used on internal combustion engines and compressors generally used in automotive and industrial applications.

Séparateurs aérauliques placés à l'entrée des moteurs à combustion interne et des compresseurs — Détermination des performances

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 5011

Fourth edition

2020-09

Inlet air cleaning equipment for

internal combustion engines and

compressors — Performance testing

Séparateurs aérauliques placés à l'entrée des moteurs à combustion

interne et des compresseurs — Détermination des performances

Reference number

©

ISO 2020

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

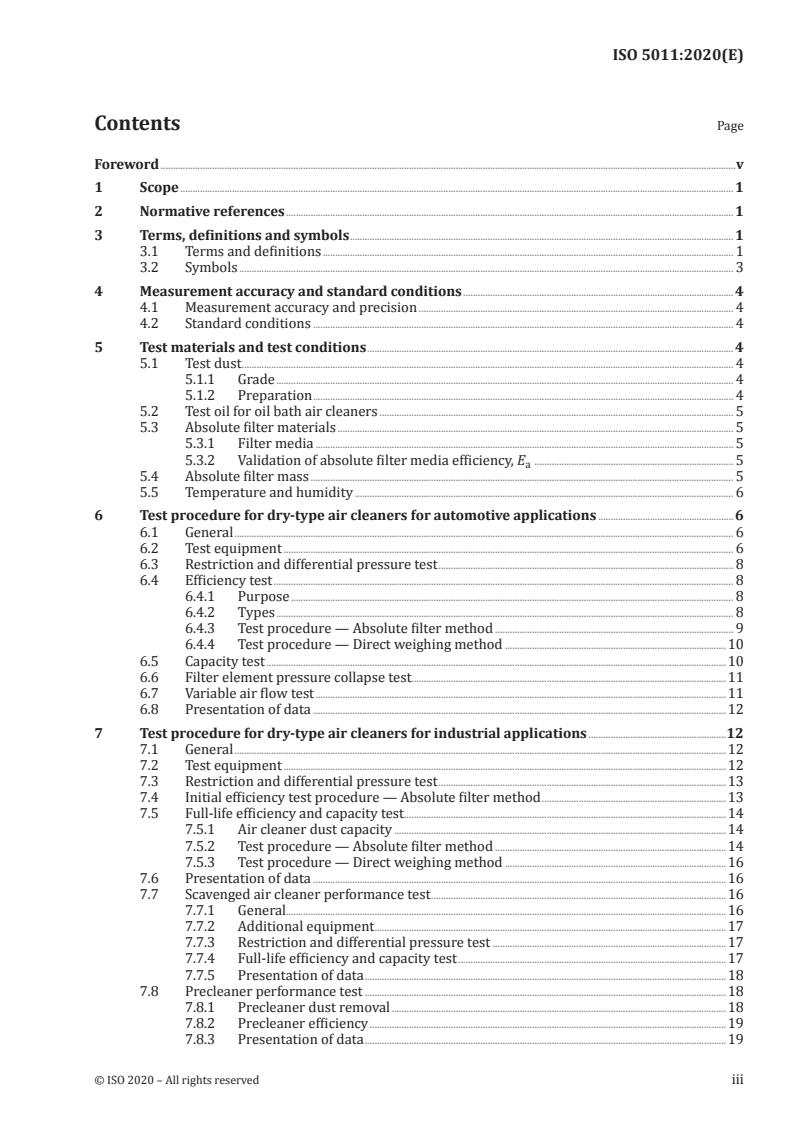

Contents Page

Foreword .v

1 Scope . 1

2 Normative references . 1

3 Terms, definitions and symbols . 1

3.1 Terms and definitions . 1

3.2 Symbols . 3

4 Measurement accuracy and standard conditions . 4

4.1 Measurement accuracy and precision . 4

4.2 Standard conditions . 4

5 Test materials and test conditions . 4

5.1 Test dust . 4

5.1.1 Grade . 4

5.1.2 Preparation . 4

5.2 Test oil for oil bath air cleaners . 5

5.3 Absolute filter materials . 5

5.3.1 Filter media . 5

5.3.2 Validation of absolute filter media efficiency, E . 5

a

5.4 Absolute filter mass . 5

5.5 Temperature and humidity . 6

6 Test procedure for dry-type air cleaners for automotive applications .6

6.1 General . 6

6.2 Test equipment . 6

6.3 Restriction and differential pressure test . 8

6.4 Efficiency test . 8

6.4.1 Purpose . 8

6.4.2 Types . 8

6.4.3 Test procedure — Absolute filter method . 9

6.4.4 Test procedure — Direct weighing method .10

6.5 Capacity test .10

6.6 Filter element pressure collapse test.11

6.7 Variable air flow test .11

6.8 Presentation of data .12

7 Test procedure for dry-type air cleaners for industrial applications .12

7.1 General .12

7.2 Test equipment .12

7.3 Restriction and differential pressure test .13

7.4 Initial efficiency test procedure — Absolute filter method .13

7.5 Full-life efficiency and capacity test.14

7.5.1 Air cleaner dust capacity .14

7.5.2 Test procedure — Absolute filter method .14

7.5.3 Test procedure — Direct weighing method .16

7.6 Presentation of data .16

7.7 Scavenged air cleaner performance test .16

7.7.1 General.16

7.7.2 Additional equipment . .17

7.7.3 Restriction and differential pressure test .17

7.7.4 Full-life efficiency and capacity test .17

7.7.5 Presentation of data .18

7.8 Precleaner performance test .18

7.8.1 Precleaner dust removal .18

7.8.2 Precleaner efficiency .19

7.8.3 Presentation of data .19

7.9 Secondary element test procedure .19

7.9.1 General.19

7.9.2 Specific efficiency test .19

7.9.3 Expression of results .20

8 Test procedure for industrial applications of oil bath air cleaners.20

8.1 General .20

8.2 Test equipment and conditions .20

8.3 Restriction and differential pressure test .21

8.4 Oil carry-over test .21

8.5 Full life efficiency and capacity test .21

8.6 Recovery test .22

8.7 Presentation of data .22

Annex A (normative) Explanation of restriction, differential pressure and pressure loss of

an air cleaner .23

Annex B (normative) Test equipment .25

Annex C (informative) Report sheet on performance testing of air cleaner equipment

according to ISO 5011 — Automotive application .35

Annex D (informative) Report sheet on performance testing of air cleaner equipment

according to ISO 5011 — Industrial application .36

Annex E (informative) Presentation of results — Air cleaner restriction/differential

pressure versus flow.38

Annex F (informative) Presentation of results — Air cleaner capacity .39

Annex G (normative) Airflow and resistance corrections to standard conditions .40

Annex H (normative) Penetration sensitivity .42

Bibliography .50

iv © ISO 2020 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see www .iso .org/

iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 22, Road vehicles, Subcommittee SC 34,

Propulsion, powertrain and powertrain fluids.

This fourth edition cancels and replaces the third edition (ISO 5011:2014), which has been technically

revised. It also incorporates the Amendment ISO 5011:2014/Amd.1:2018. The main changes compared

to the previous edition are as follows:

— added a validation procedure for verifying efficiency measurements;

— revised recommended ISO dust injector table;

— added formula for precleaner efficiency method;

— removed requirement for secondary element collapse test;

— added Annex H (Penetration sensitivity);

— added a new dust injector.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

INTERNATIONAL STANDARD ISO 5011:2020(E)

Inlet air cleaning equipment for internal combustion

engines and compressors — Performance testing

1 Scope

This document establishes and specifies uniform test procedures, conditions, equipment and a

performance report to permit the direct laboratory performance comparison of air cleaners.

The basic performance characteristics of greatest interest are air flow restriction or differential

pressure, dust collection efficiency, dust capacity and oil carry-over on oil bath air cleaners. This test

code therefore deals with the measurement of these parameters.

This document is applicable to air cleaners used on internal combustion engines and compressors

generally used in automotive and industrial applications.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 5167-1, Measurement of fluid flow by means of pressure differential devices inserted in circular cross-

section conduits running full — Part 1: General principles and requirements

ISO 12103-1, Road vehicles — Test contaminants for filter evaluation — Part 1: Arizona test dust

3 Terms, definitions and symbols

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

3.1 Terms and definitions

3.1.1

air filter

air cleaner

device which removes particles suspended in the intake air as it is drawn into the engine

3.1.2

filter element

replaceable part of the air filter (3.1.1), consisting of the filter material and carrying frame

3.1.3

secondary element

air cleaner (3.1.1) element fitted downstream of the primary element for the purpose of providing the

engine with protection against dust in the event of

a) certain types of primary element failure, or

b) dust being present during the removal of the primary element for servicing

3.1.4

unit under test

either a single air cleaner (3.1.1) element or a complete air cleaner assembly

3.1.5

single-stage air cleaner

air cleaner (3.1.1) which does not incorporate a separate precleaner (3.1.7)

3.1.6

multistage air cleaner

air cleaner (3.1.1) consisting of two or more stages, the first usually being a precleaner (3.1.7), followed

by one or more filter elements (3.1.2)

Note 1 to entry: If two elements are used, the first is called the primary element and the second one is called the

secondary element (3.1.3).

3.1.7

precleaner

device usually using inertial or centrifugal means to remove a portion of the test dust prior to reaching

the filter element (3.1.2)

3.1.8

test air flow

measure of the quantity of air drawn through the air cleaner (3.1.1) outlet per unit time

Note 1 to entry: The flow rate is expressed in cubic metres per minute corrected to standard conditions.

3.1.9

rated air flow

flow rate specified by the user or manufacturer

Note 1 to entry: It may be used as the test air flow (3.1.8).

3.1.10

scavenged air flow

measure of the quantity of air used to remove the collected dust from a precleaner (3.1.7)

Note 1 to entry: It is expressed as a percentage of the test air flow (3.1.8).

3.1.11

static pressure

pressure in a duct, at the observed air flow rate, measured by connecting a pressure gauge to a hole or

holes drilled in the wall of the duct

Note 1 to entry: In the tests specified in this document, a static pressure is measured by a manometer (usually a

liquid manometer) as a negative pressure difference against the atmospheric pressure and in the formula this is

treated as a positive value.

3.1.12

restriction

static pressure (3.1.11) measured immediately downstream of the unit under test (3.1.4)

3.1.13

differential pressure

difference in static pressure (3.1.11) measured immediately upstream and downstream of the unit under

test (3.1.4)

2 © ISO 2020 – All rights reserved

3.1.14

pressure loss

measure of the loss of energy caused by an air cleaner (3.1.1) at the observed air flow rate

Note 1 to entry: It is expressed as the differential pressure (3.1.13) corrected for any difference in the dynamic

head at the measuring points.

Note 2 to entry: For further information, see Annex A.

3.1.15

absolute filter

filter downstream of the unit under test (3.1.4) that retains the contaminant passed by the unit under test

3.1.16

efficiency

ability of the air cleaner (3.1.1) or the unit to remove contaminant mass under specified test conditions

3.1.17

capacity

quantity of contaminant removed by the unit under test (3.1.4) in producing specified terminal

conditions

3.1.18

oil carry-over

appearance of oil at the cleaner outlet

3.1.19

test terminal condition

condition, relating to an air cleaner (3.1.1), the occurrence of which signifies the end of the test

Note 1 to entry: A test terminal condition may be, for example, any one of the following: the restriction (3.1.12)

or the differential pressure (3.1.13) reaches a specified or agreed terminal value; the dust-removing efficiency

(3.1.16) or some other performance parameter falls to a specified or agreed value; oil carry-over (3.1.18) occurs;

a dust pot becomes filled.

3.1.20

automotive application

air cleaner (3.1.1) generally used for internal combustion engines in passenger cars

3.1.21

industrial application

air cleaner (3.1.1) generally used for internal combustion engines in heavy-duty trucks, construction

equipment and agricultural tractors

3.2 Symbols

The following applied units, according to ISO 80000-1, are used.

Name Symbol Unit

Density ρ kg/m

Differential pressure Δp Pa

d

Mass m g

Mass flow rate q kg/min

m

Pressure p Pa

Pressure loss Δp Pa

l

Restriction Δp Pa

r

Temperature T °C

Time t s

Name Symbol Unit

Velocity v m/s

Volume flow rate q m /min

V

4 Measurement accuracy and standard conditions

4.1 Measurement accuracy and precision

Measure the air flow rate to within ±2 % of the actual value, except for the variable air flow test when

accuracy may be ±2 % of the maximum value of the cyclic flow rate through the cleaner.

Measure the differential pressure and restriction to within 25 Pa for pressure readings up to 10 kPa,

within 1 % of reading for higher pressures.

Measure the temperature to within 0,5 °C of the actual value.

Measure the mass to within 0,1 g with the exception of absolute filter mass to be measured at 0,01 g and

with the exception of the feeder mass to be measured at 1 %.

Measure the relative humidity (RH) with an accuracy of ±2 % RH.

Measure the barometric pressure to within 0,3 kPa.

The measurement equipment shall be calibrated at regular intervals to ensure the required accuracy.

Follow Annex H to determine the reporting precision of your efficiency measurement.

4.2 Standard conditions

All airflow measurements shall be corrected to a standard condition of 20 °C at 101,3 kPa.

See Annex G.

5 Test materials and test conditions

5.1 Test dust

5.1.1 Grade

The test dust to be used shall be ISO 12103-1, A.2 (ISO fine) or ISO 12103-1, A.4 (ISO coarse), subject

to agreement between the filter manufacturer and client. The chemical analysis and the particle size

distribution shall conform to ISO 12103-1.

In the absence of an agreement on the dust:

— for single-stage filters, use ISO fine test dust, and

— for multistage filters, use ISO coarse test dust.

5.1.2 Preparation

Before using the test dust, a quantity sufficient to cover the test requirements shall be mixed to

ensure that no stratification / clumping has occurred. The test dust shall then be allowed to become

acclimatised to a constant mass under the prevailing test conditions.

NOTE To ensure a constant rate of dust feed with some dust feeders, it can be found necessary to heat the

dust prior to being acclimated to the environment.

4 © ISO 2020 – All rights reserved

5.2 Test oil for oil bath air cleaners

The oil used for testing oil bath air cleaners shall be that specified by the filter manufacturer and agreed

by the user for use at the appropriate ambient temperature. If an oil is not specified, the test oil shall be

a heavy-duty oil and the viscosity at the temperature of the test shall be adjusted as follows:

— 85 mm /s for oil carry-over and restriction/differential pressure tests;

— 330 mm /s for efficiency and capacity tests, including an oil carry-over test after the capacity test.

5.3 Absolute filter materials

5.3.1 Filter media

The absolute filter may consist of fibreglass media with a minimum thickness of 12,7 mm and a

3 1)

minimum density of 9,5 kg/m . The fibre diameter shall be 0,76 µm to 1,27 µm and the moisture

absorption should be less than 1 % by mass after exposure to 50 °C and 95 % relative humidity for 96 h.

The absolute filter media shall be installed with nap side facing upstream, in an airtight holder that

adequately supports the media. The face velocity shall not exceed approximately 0,8 m/s to maintain

media integrity.

As an alternative, a non-woven filter media with the efficiency described in 5.3.2 may be used.

To reduce any subsequent errors in the measurements caused by losses of fibres or materials, the

absolute filter shall be subject to a flow of at least 110 % of the rated flow of ambient air for a minimum

of 5 min before the first (new) test weighing.

NOTE The use of an absolute filter with a backing will minimize fibre loss.

5.3.2 Validation of absolute filter media efficiency, E

a

Arrange two absolute filters in tandem. Perform a filter efficiency test and determine the mass increase

of each absolute filter according to the test procedure given in 6.4.3 or 7.5.2:

Δm

A

E = ×100 (1)

a

ΔΔmm+

AB

where

E is the absolute filter efficiency, expressed as a percentage;

a

Δm is the mass increase of the upstream absolute filter;

A

Δm is the mass increase of the downstream absolute filter.

B

The absolute filter efficiency should be a minimum of 99 % for the contaminant presented to it.

5.4 Absolute filter mass

The absolute filter shall be weighed, to the nearest 0,01 g, after the mass has stabilized. Weight

stabilization may be achieved by storage in a ventilated oven at a constant temperature of 105 °C ± 5 °C.

The absolute filter shall be weighed inside the oven. Alternatively, air conditioned following 5.5 may

be drawn through the absolute filter for 15 min and then the filter is weighed. Evaluate conditioning

method per 5.4.1.

1) A suitable material is commercially available. Details may be obtained from the secretariat of ISO/TC 22.

5.4.1 Validation of the absolute filter weighing method

Using the method of choice, the absolute pad weight method shall be performed once each day for three

days and evaluate results per Annex H.

5.5 Temperature and humidity

All tests shall be conducted with air entering the air cleaner at a temperature of 23 °C ± 5 °C. Tests shall

be conducted at a relative humidity of (55 ± 15) %, the permissible variation at each weighing stage

throughout each single test being ±2 %.

The test results of an air cleaner will be affected by the relative humidity of the air passing through it

and the results of otherwise identical tests carried out near the two extremes of the permitted range of

relative humidity may not be directly comparable. The tests should be conducted within the narrowest

range of temperature and humidity possible.

6 Test procedure for dry-type air cleaners for automotive applications

6.1 General

Performance tests shall be performed on a complete air cleaner assembly or on a single air cleaner

element; tests on a complete air cleaner assembly are preferred. The tests shall consist of an air flow

restriction/differential pressure test, an efficiency test and a capacity test. In addition, a pressure

collapse test shall be performed on the air filter element.

6.2 Test equipment

6.2.1 Typical arrangements to determine resistance to air flow, dust capacity, dust removal

characteristics and rupture collapse characteristics are shown in Annex B, Figures B.1 and B.6 to B.11.

Use a dust feeder which when used with the dust injector in Figures B.2, B.3 and B.18 is capable of

metering dust over the range of delivery rates required. This dust feed system shall not change the

primary particle size distribution of the contaminant. The air feed pressure shall be 100 kPa minimum.

The heavy-duty injector pressure shall be a gauge pressure of 280 kPa minimum.

The dust feed system shall be validated as follows.

a) Charge the dust feeder with a pre-weighed amount of test dust.

b) Simultaneously start the dust feed system and timer.

c) At 5 min intervals, determine the mass of dust dispensed. Continue mass determinations of dust

increments for 30 min.

d) Adjust the dust feeder until the average delivery rate is within 5 % of the desired rate and the

deviation in delivery rate from the average is not more than 5 %.

6.2.2 Use a dust-transfer tube between the dust feeder and the injector of a size suitable to maintain

dust suspension. Sedimentation losses in the transfer tube should be avoided by having the tube as short

as possible and grounded.

6 © ISO 2020 – All rights reserved

6.2.3 Use the dust injector described in Table 1 and shown in Figures B.2, B.3 and B.18.

Table 1 — Recommended ISO dust injectors (see Figures B.2 B.3 and B.18)

Dust feed rate per injector

0 to 5 5 to 26 >26

(g/min)

Light-duty injector or

Heavy-duty injectors

Injector type Light-duty injector heavy-duty injectors

(A or B)

(A or B)

If an array of injectors is used, special care shall be taken to make sure the dust fed is distributed evenly

between each injector for two reasons: First, to get homogeneous dust distribution in the airstream and

second, to make sure the maximum or minimum feed rate for the injectors being used is not exceeded.

Where dust feed rates greater than this are required, more than one injector will have to be used. It

should be noted that the design of the system feeding test dust to the injector may affect this maximum

rate of dust feed. The maximum attainable dust feed rate should therefore be determined prior to the

dust feed/injector system being used for tests.

Injector nozzles are subject to natural erosion. Erosion may affect the distribution and delivery of test

contaminant. Therefore, it is recommended to use a design with replaceable parts.

6.2.4 Use an inlet tube conforming to Figure B.4. The dust injector and inlet tube shall be positioned in

such a way that there is a uniform dust distribution and no loss of dust.

6.2.5 Use a manometer or other differential-pressure measuring device with the specified accuracy.

6.2.6 For air cleaner assembly testing, use a housing and set-up agreed upon by the manufacturer and

user conforming to Figure B.11. For air filter element testing, use a test set-up and shroud conforming

to Figures B.1 and B.5 or an arrangement as shown in Figures B.6 or B.7. Where the test equipment is

as shown in Figure B.6, the dust is fed into the chamber and, to ensure that it does not adhere to the

walls and is evenly distributed, dry compressed air jets on flexible tubing should be provided in the test

chamber, arranged so to agitate any dust that settles out.

When using compressed air for agitating dust, care shall be taken not to eject any dust out of the

chamber. To ensure that no dust is ejected from the chamber, a negative pressure should be maintained

between the chamber and the atmosphere.

6.2.7 Use an outlet tube conforming to Figure B.4. The cross-section shall be the same as the air cleaner

outlet. In the case of non-uniform flow conditions caused by special outlet tubes, special precautions may

be required.

6.2.8 Use an air flow rate measuring system having the accuracy described in 4.1.

Validate the air flow rate measuring system. The air flow meter shall be of an acceptable design, such

as a calibrated orifice and manometer conforming to ISO 5167-1. The orifice unit shall be permanently

marked such that it can be identified after calibration. Corrections shall be made for variations in

absolute pressure and temperature at the meter inlet and the air flow rate shall be expressed in cubic

metres per minute corrected to standard conditions (see 4.2).

6.2.9 Use an air flow rate control system capable of maintaining the indicated flow rate to within 2 %

of the selected value during steady-state and variable air flow operation.

6.2.10 Use a blower/exhauster for inducing air flow through the system, which has adequate flow rate

and pressure characteristics for the filters to be tested. Pulsation of flow rate shall be so low that it is not

measurable by the flow rate measuring system.

6.2.11 Grounding is required for all test apparatus to reduce the effects of static charges and to improve

the consistency of the test results. Grounding of metallic and non-metallic surfaces, housings, dust

transport tubes, injectors and associated hardware is recommended.

6.3 Restriction and differential pressure test

6.3.1 The purpose of this test is to determine the restriction/differential pressure/pressure loss

across the unit under test which will result when air is passed through under predetermined conditions.

Airflow restriction or differential pressure is measured with a clean filter element, or elements, at five

equally spaced airflows of between 50 % and 150 % of the rated air flow, or as agreed upon between the

user and manufacturer.

6.3.2 Condition the unit to the air flow at which the unit is tested for at least 15 min under the

temperature and humidity conditions specified in 5.5.

6.3.3 Set up the test stand as shown in Figures B.8 or B.9 and Figures B.14 or B.15. Seal all joints to

prevent air leaks. Connect pressure taps.

6.3.4 Measure and record the restriction and the differential pressure versus the flow rate at

approximately 50 %, 75 %, 100 %, 125 % and 150 % of the rated air flow, or as agreed upon between the

user and manufacturer.

6.3.5 Record the ambient temperature, barometric pressure and relative humidity.

6.3.6 Correct the recorded restriction and differential pressure to standard conditions in accordance

with Annex G, Formula (G.1).

6.3.7 For pressure loss determination, use the formula given in Annex A.

6.3.8 Plot the results, for example as shown in Annex E, Figure E.1 or equivalent.

6.4 Efficiency test

6.4.1 Purpose

The purpose of this test is to determine the retention capabilities of the unit under test. This test can

be conducted with either constant or variable air flow and with coarse dust or fine test dust. If desired,

efficiency tests can be performed concurrently with capacity tests (see 6.5). Determination of the

efficiency at constant test air flow can be performed at the rated air flow or any percentage thereof,

as agreed upon by the user and manufacturer. Determination of efficiency at variable air flow can be

performed using variable air flow cycle according to 6.7.

6.4.2 Types

Three types of efficiency tests can be performed, as follows:

a) full-life efficiency determined when the terminal condition, i.e. the terminating differential

pressure is reached;

b) incremental efficiency determined when, for example, 10 %, 25 % and 50 % of the terminating

differential pressure minus the initial differential pressure is reached;

c) initial efficiency determined after the addition of 20 g of contaminant or the number of grams

numerically equivalent to six times the air flow in cubic metres per minute, whichever is the

greater.

8 © ISO 2020 – All rights reserved

6.4.3 Test procedure — Absolute filter method

6.4.3.1 Based on the test flow, calculate the test dust feed rate using a dust concentration of 1,0 g/m of

3 3

air; in special cases (e.g. small filters) 0,25 g/m or 0,5 g/m may be allowed.

6.4.3.2 Condition the unit under test according to 6.3.2, then measure and record the mass.

NOTE Conditioning of the absolute filter pad and air cleaner can be performed concurrently.

6.4.3.3 Weigh the absolute filter pad as specified in 5.4 and record mass before assembly within

absolute filter housing.

6.4.3.4 Set up test stand as shown in Figure B.11 for air cleaner assemblies, or as shown in Figure B.1,

B.6 or B.7 for air filter elements. Seal all joints to prevent air leakage.

6.4.3.5 Record the temperature, barometric pressure and relative humidity.

6.4.3.6 Prepare the specified test dust according to 5.1 and weigh out the quantity required for test in

a suitable test container. For full-life efficiency tests, the quantity should be approximately 125 % of the

estimated capacity of the unit under test. Record the mass of the container and dust to the nearest 0,1 g.

Specified in 4.1.

6.4.3.7 Start the air flow through the test stand and stabilize at the test flow rate. Record the differential

pressure.

6.4.3.8 Load the dust feeder from the dust container and adjust the feed rate to inject dust at the

concentration calculated in 6.4.3.1. Reload the dust feeder from the dust container throughout the test as

necessary.

6.4.3.9 At specified time intervals (a minimum of five points is recommended), record the differential

pressure in accordance with Annex A at the test flow and the elapsed test time.

6.4.3.10 Continue the test until the specified terminal condition is reached.

6.4.3.11 Record the temperature, barometric pressure and relative humidity.

6.4.3.12 The dust on the exterior surfaces of a cleaner assembly or any which may have settled in the test

chamber/ducting on the inlet side of a test element shall be collected carefully and its weight recorded.

This dust shall then be discarded due to potential change in distribution.

6.4.3.13 Reweigh the dust container and add the result to the weight recorded in 6.4.3.12. Subtract this

sum from the mass recorded in 6.4.3.6. The difference is the mass of dust fed to the unit under test. The

mass of dust fed to the unit under test can be determined from weight loss of the dust feeder directly.

6.4.3.14 Carefully remove the unit under test without losing any dust. Note any evidence of seal leakage

or unusual conditions. Weigh the unit, per 4.1 in grams. The increase in mass of the unit under test is this

mass minus the mass determined in 6.4.3.2. In the full-life efficiency test [see 6.4.2 a)] this increase in

mass is the capacity of the unit under test.

6.4.3.15 Brush any observed dust on the downstream side of the test unit onto the absolute filter.

Carefully remove the absolute filter. Repeat step 6.4.3.3 per 4.1 and determine the difference in mass.

This is the increase in mass of the absolute filter.

6.4.3.16 Calculate the material balance, B, of the test dust. For the test to be valid, this value shall be

within the range 0,98 to 1,02:

ΔΔmm+

Fu

B = (2)

m

D

where

Δm is the increase in mass of the absolute filter;

F

Δm is the increase in mass of the unit under test;

u

m is the total mass of the dust fed.

D

6.4.3.17 Calculate the efficiency, E (expressed as a percentage), by the following method:

Δm

u

E= ×100 (3)

ΔΔmm+

uF

where the symbols are as in Formula (2).

6.4.4 Test procedure — Direct weighing method

NOTE This method is a less precise efficiency determination than the absolute filter method.

The direct weighing method may be used for cumulative efficiency determination where the humidity

can be controlled to within ±1,0 % and the accuracy of the increase in mass of the filter determined to

within 0,1 %.

Where a suitable large, accurate balance is available, it is permissible to use a direct weighing method of

assessing the performance of the unit under test. In such cases the air cleaner under test shall be tested

according to the procedure in 6.4.3 omitting the operations described in 6.4.3.3, 6.4.3.15, 6.4.3.16 and

6.4.3.17. Calculate the efficiency, E (expressed as a percentage), as follows:

Δm

u

E=×100 (4)

m

D

where the symbols are as in Formula (2).

The test report should indicate the method of efficiency determination used.

6.5 Capacity test

6.5.1 The purpose of this test is to determine the total mass gain of the unit under test at the terminating

condition. This test can be conducted with either constant or variable air flow and with coarse or fine

test dust contaminant. If desired, the capacity determination can be performed concurrently with the

efficiency test (see 6.4).

6.5.2 Condition the unit according to 6.3.2. Perform the test as described in 6.4.3 or 6.4.4.

10 © ISO 2020 – All rights reserved

6.5.3 Assuming a constant ratio of elapsed time versus dust feed of the test unit, record the data and

plot the curve of restriction versus mass gain, see reference plot in Annex F, Figure F1. Refer to 6.4.3.9 for

restriction and time interval data.

Determine the mass gain values as follows:

t

l

ΔΔm =× m (5)

t UT

t

T

where

Δm is the increase in mass at the end of each time interval;

t

t is the total time at the end of interval;

t is the total time at the end of test;

T

Δm is the total increase in mass of the unit under test at the end of test.

UT

6.5.4 In the case of the terminal condition being the restriction, terminal condition shall not include

the restriction added by the dust mixing device and test shroud.

6.6 Filter element pressure collapse test

6.6.1 The purpose of this test is to determine the ability of an air filter element to withstand a specified

differential pressure and/or to determine the differential pressure at which collapse occurs.

6.6.2 Set up the test stand to perform the basic dust capacity test in accordance with Figure B.1, B.6,

B.7 or B.11. Either the element from the prior capacity or efficiency test or a new element can be used for

this test.

6.6.3 Increase the air flow through the stand and, if necessary, the feed dust at any convenient rate

until the specified differential pressure is reac

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.