ISO 19825:2018

(Main)Road vehicles — Liquefied petroleum gas (LPG) refuelling connector

Road vehicles — Liquefied petroleum gas (LPG) refuelling connector

This document applies to Liquefied Petroleum Gas vehicle nozzles and receptacles, hereinafter referred to as devices, constructed entirely of new, unused parts and materials. Liquefied Petroleum Gas fuelling connectors consist of the following components, as applicable: a) nozzle (mounted on dispenser side) (see Clause 5); b) receptacle (mounted on vehicle) (see Clause 7). This document applies to devices which have a gauge service pressure in the range of 110 kPa (Butane rich at 20 °C) and 840 kPa (Propane at 20 °C), hereinafter referred to as [see 9.1 c)]: — J15; — K15. This document also applies to: — devices with standardized mating components; — connectors which prevent Liquefied Petroleum Gas vehicles from being fuelled by other gaseous fuels station dispensers; and — Liquefied Petroleum Gas in accordance with ISO 9162. NOTE All references to pressures (kPa) throughout this document are considered gauge pressures unless otherwise specified. This document does not apply to the fuel system of vehicle, with the exception of the Liquefied Petroleum Gas receptacle.

Véhicules routiers — Connecteur de remplissage en gaz de pétrole liquéfié (GPL)

General Information

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 19825

First edition

2018-11

Road vehicles — Liquefied petroleum

gas (LPG) refuelling connector

Véhicules routiers — Connecteur de remplissage en gaz de pétrole

liquéfié (GPL)

Reference number

©

ISO 2018

© ISO 2018

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2018 – All rights reserved

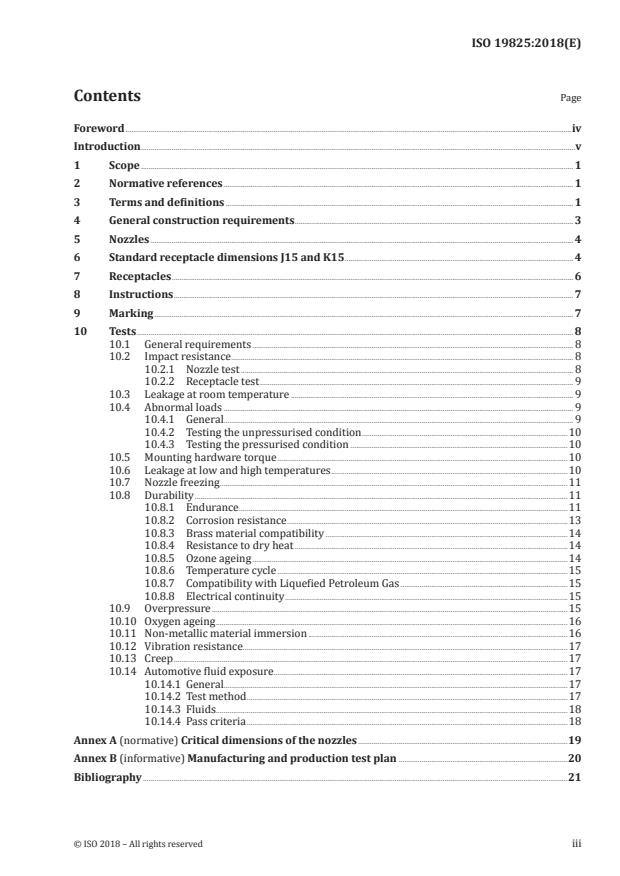

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 General construction requirements . 3

5 Nozzles . 4

6 Standard receptacle dimensions J15 and K15 . 4

7 Receptacles . 6

8 Instructions . 7

9 Marking . 7

10 Tests . 8

10.1 General requirements . 8

10.2 Impact resistance . 8

10.2.1 Nozzle test . 8

10.2.2 Receptacle test . 9

10.3 Leakage at room temperature . 9

10.4 Abnormal loads . 9

10.4.1 General. 9

10.4.2 Testing the unpressurised condition .10

10.4.3 Testing the pressurised condition .10

10.5 Mounting hardware torque .10

10.6 Leakage at low and high temperatures .10

10.7 Nozzle freezing .11

10.8 Durability .11

10.8.1 Endurance .11

10.8.2 Corrosion resistance .13

10.8.3 Brass material compatibility .14

10.8.4 Resistance to dry heat .14

10.8.5 Ozone ageing .14

10.8.6 Temperature cycle .15

10.8.7 Compatibility with Liquefied Petroleum Gas .15

10.8.8 Electrical continuity .15

10.9 Overpressure .15

10.10 Oxygen ageing .16

10.11 Non-metallic material immersion .16

10.12 Vibration resistance .17

10.13 Creep .17

10.14 Automotive fluid exposure.17

10.14.1 General.17

10.14.2 Test method .17

10.14.3 Fluids . . .18

10.14.4 Pass criteria .18

Annex A (normative) Critical dimensions of the nozzles .19

Annex B (informative) Manufacturing and production test plan .20

Bibliography .21

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www .iso .org/iso/foreword .html.

This document was prepared by Technical Committee ISO/TC 22, Road vehicles, Subcommittee SC 41,

Specific aspects for gaseous fuels.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/members .html.

iv © ISO 2018 – All rights reserved

Introduction

This document was developed for the design, examination, testing and certification of newly produced

Liquefied Petroleum Gas Vehicle fuelling nozzles and receptacles only.

A nozzle compliant with this document is functionally compatible from a safety and performance

perspective with all listed receptacles of compatible profile and system pressure. Similarly, a receptacle

compliant with this document is functionally compatible from a safety and performance perspective

with all listed nozzles of compatible profile and system pressure.

These standard profiles incorporate the design specifications (mating materials, geometry and

tolerances) which can be considered in the certification of a submitted nozzle or receptacle.

INTERNATIONAL STANDARD ISO 19825:2018(E)

Road vehicles — Liquefied petroleum gas (LPG) refuelling

connector

1 Scope

This document applies to Liquefied Petroleum Gas vehicle nozzles and receptacles, hereinafter referred

to as devices, constructed entirely of new, unused parts and materials. Liquefied Petroleum Gas fuelling

connectors consist of the following components, as applicable:

a) nozzle (mounted on dispenser side) (see Clause 5);

b) receptacle (mounted on vehicle) (see Clause 7).

This document applies to devices which have a gauge service pressure in the range of 110 kPa (Butane

rich at 20 °C) and 840 kPa (Propane at 20 °C), hereinafter referred to as [see 9.1 c)]:

— J15;

— K15.

This document also applies to:

— devices with standardized mating components;

— connectors which prevent Liquefied Petroleum Gas vehicles from being fuelled by other gaseous

fuels station dispensers; and

— Liquefied Petroleum Gas in accordance with ISO 9162.

NOTE All references to pressures (kPa) throughout this document are considered gauge pressures unless

otherwise specified.

This document does not apply to the fuel system of vehicle, with the exception of the Liquefied

Petroleum Gas receptacle.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 188, Rubber vulcanized — Accelerat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.