ISO 13609:2021

(Main)Wood-based panels — Plywood — Blockboards and battenboards

Wood-based panels — Plywood — Blockboards and battenboards

This document establishes requirements for the specifications of blockboards and battenboards for general use, in dry, tropic dry/humid, and high-humid/exterior conditions. It includes requirements of materials, lay-up, physical and mechanical properties, bonding quality, formaldehyde release, conformity verification, and marking. The values listed in this document relate to product properties, but they are not characteristic values to be used in design calculations.

Panneaux à base de bois — Contreplaqués — Panneaux lattés avec lattes étroites et avec lattes larges

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 13609

Second edition

2021-06

Wood-based panels — Plywood —

Blockboards and battenboards

Panneaux à base de bois — Contreplaqués — Panneaux lattés avec

lattes étroites et avec lattes larges

Reference number

©

ISO 2021

© ISO 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2021 – All rights reserved

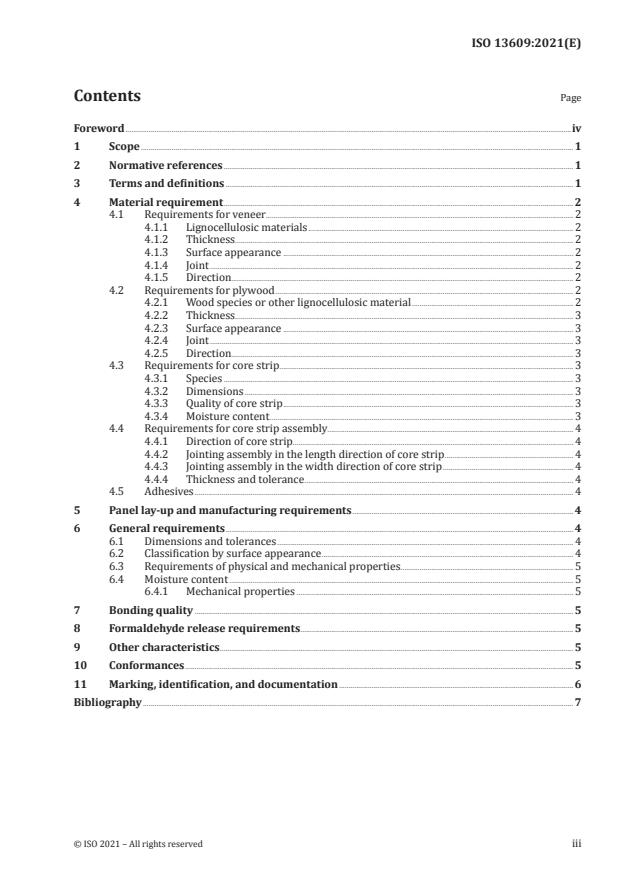

Contents Page

Foreword .iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Material requirement . 2

4.1 Requirements for veneer. 2

4.1.1 Lignocellulosic materials . 2

4.1.2 Thickness . 2

4.1.3 Surface appearance . 2

4.1.4 Joint . 2

4.1.5 Direction. 2

4.2 Requirements for plywood . 2

4.2.1 Wood species or other lignocellulosic material . 2

4.2.2 Thickness . 3

4.2.3 Surface appearance . 3

4.2.4 Joint . 3

4.2.5 Direction. 3

4.3 Requirements for core strip. 3

4.3.1 Species . 3

4.3.2 Dimensions . 3

4.3.3 Quality of core strip . 3

4.3.4 Moisture content . 3

4.4 Requirements for core strip assembly . 4

4.4.1 Direction of core strip. 4

4.4.2 Jointing assembly in the length direction of core strip . 4

4.4.3 Jointing assembly in the width direction of core strip . 4

4.4.4 Thickness and tolerance . 4

4.5 Adhesives . 4

5 Panel lay-up and manufacturing requirements . 4

6 General requirements . 4

6.1 Dimensions and tolerances . 4

6.2 Classification by surface appearance . 4

6.3 Requirements of physical and mechanical properties. 5

6.4 Moisture content . 5

6.4.1 Mechanical properties . 5

7 Bonding quality . 5

8 Formaldehyde release requirements . 5

9 Other characteristics . 5

10 Conformances . 5

11 Marking, identification, and documentation . 6

Bibliography . 7

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 89, Wood-based panels, Subcommittee

SC 3, Plywood.

This second edition cancels and replaces the first edition (ISO 13609:2014), which has been technically

revised.

The main changes compared to the previous edition are as follows:

— inclusion of a reference to ISO 2426-4;

— deleted reference to ISO/IEC Guide 65:1996.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

iv © ISO 2021 – All rights reserved

INTERNATIONAL STANDARD ISO 13609:2021(E)

Wood-based panels — Plywood — Blockboards and

battenboards

1 Scope

This document establishes requirements for the specifications of blockboards and battenboards for

general use, in dry, tropic dry/humid, and high-humid/exterior conditions. It includes requirements

of materials, lay-up, physical and mechanical properties, bonding quality, formaldehyde release,

conformity verification, and marking.

The values listed in this document relate to product properties, but they are not characteristic values to

be used in design calculations.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 1954, Plywood — Tolerances on dimensions

ISO 2074, Plywood — Vocabulary

ISO 2426-2:2020, Plywood — Classification by surface appearance — Part 2: Hardwood

ISO 2426-3:2000, Plywood — Classification by surface appearance — Part 3: Softwood

ISO 2426-4:2018, Plywood — Classification by surface appearance — Part 4: Palm-plywood

ISO 9426, Wood-based panels — Determination of dimensions of panels

ISO 12460-1, Wood-based panels — Determination of formaldehyde release — Part 1: Formaldehyde

emission by the 1-cubic-metre chamber method

ISO 12460-3, Wood-based panels — Determination of formaldehyde release — Part 3: Gas analysis method

ISO 12460-4, Wood-based panels — Determination of formaldehyde release — Part 4: Desiccator method

ISO 12465:2007, Plywood — Specifications

ISO 12466-1, Plywood — Bonding quality — Part 1: Test methods

ISO 12466-2, Plywood — Bonding quality — Part 2: Requirements

ISO 16978, Wood-based panels — Determination of modulus of elasticity in bending and of bending strength

ISO 16979, Wood-based panels — Determination of moisture content

ISO 16999, Wood-based panels — Sampling and cutting of test pieces

ISO 18775, Veneers — Terms and definitions, determination of physical characteristics and tolerances

3 Terms and definitions

For the purposes of this document, the terms and definitions in ISO 2074, ISO 12465, and ISO 18775 and

the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1

core strip

individual wood pieces with rectangular cross section which are assembled to form the solid core

4 Material requirement

4.1 Requirements for veneer

The following requirements apply to veneer at the time of pressing.

4.1.1 Lignocellulosic materials

Any wood species or other lignocellulosic material is permitted.

Veneers shall be identified according to the species, species group, or mechanical properties.

When veneers of different species are used to form a layer, these veneers shall be of similar mechanical

and physical properties.

4.1.2 Thickness

The thickness, t, of veneer shall be 0,55 mm ≤ t ≤ 6,0 mm. When veneers are used to cover a core, the

thickness of veneers adjacent to the core shall not be less than 1,5 mm.

4.1.3 Surface appearance

The surface

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.