ISO 11257:2022

(Main)Iron ores for shaft direct-reduction feedstocks — Determination of the low-temperature reduction-disintegration index and degree of metallization

Iron ores for shaft direct-reduction feedstocks — Determination of the low-temperature reduction-disintegration index and degree of metallization

This document specifies a method to provide a relative measure for evaluating the degree of size degradation and degree of metallization of iron ores, when reduced under conditions resembling those prevailing in shaft direct-reduction processes. This document is applicable to lump ores and hot-bonded pellets.

Minerais de fer pour charges utilisées dans les procédés par réduction directe — Détermination de l'indice de désintégration par réduction à basse température et du degré de métallisation

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 11257

Fourth edition

2022-03

Iron ores for shaft direct-reduction

feedstocks — Determination of

the low-temperature reduction-

disintegration index and degree of

metallization

Minerais de fer pour charges utilisées dans les procédés par réduction

directe — Détermination de l'indice de désintégration par réduction à

basse température et du degré de métallisation

Reference number

© ISO 2022

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

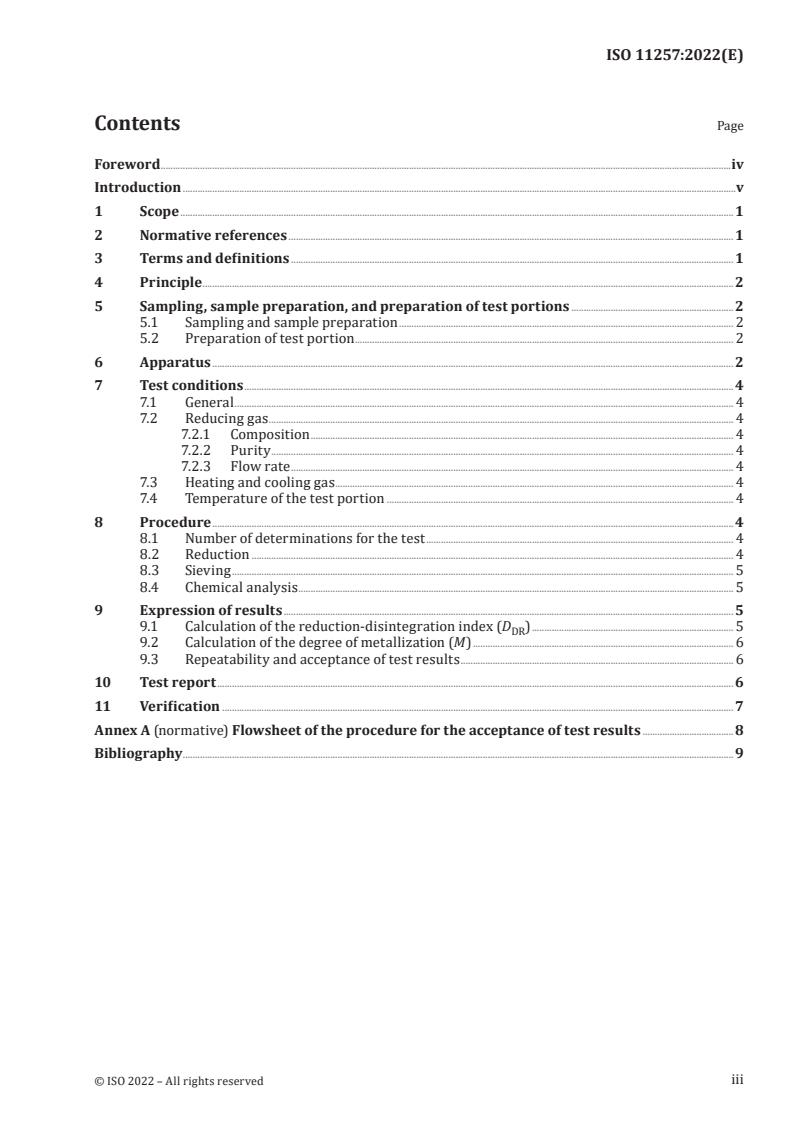

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Principle . 2

5 Sampling, sample preparation, and preparation of test portions .2

5.1 Sampling and sample preparation . 2

5.2 Preparation of test portion . 2

6 Apparatus . 2

7 Test conditions .4

7.1 General . 4

7.2 Reducing gas . 4

7.2.1 Composition . 4

7.2.2 Purity . 4

7.2.3 Flow rate . 4

7.3 Heating and cooling gas . 4

7.4 Temperature of the test portion . 4

8 Procedure .4

8.1 Number of determinations for the test . 4

8.2 Reduction . 4

8.3 Sieving . 5

8.4 Chemical analysis . 5

9 Expression of results . 5

9.1 Calculation of the reduction-disintegration index (D ) . 5

DR

9.2 Calculation of the degree of metallization (M) . 6

9.3 Repeatability and acceptance of test results . 6

10 Test report . 6

11 Verification . 7

Annex A (normative) Flowsheet of the procedure for the acceptance of test results .8

Bibliography . 9

iii

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 102, Iron ore and direct reduced iron,

Subcommittee SC 3, Physical testing.

This fourth edition cancels and replaces the third edition (ISO 11257:2015), which has been technically

revised to include ISO 16878 as a reference for the metallic iron determination.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

iv

Introduction

This document concerns one of a number of physical test methods that have been developed to

measure various physical parameters and to evaluate the behaviour of iron ores, including reducibility,

disintegration, crushing strength, apparent density, etc. This method was developed to provide a

uniform procedure, validated by collaborative testing, to facilitate comparisons of tests made in

different laboratories.

The results of this test have to be considered in conjunction with other tests used to evaluate the quality

of iron ores as feedstocks for direct reduction processes.

This document can be used to provide test results as part of a production quality control system, as a

basis of a contract, or as part of a research project.

v

INTERNATIONAL STANDARD ISO 11257:2022(E)

Iron ores for shaft direct-reduction feedstocks —

Determination of the low-temperature reduction-

disintegration index and degree of metallization

CAUTION — This document can involve hazardous operations and equipment. document does

not purport to address all of the safety issues associated with its use. It is the responsibility of

the user of this document to establish appropriate safety and health practices and determine

the applicability of regulatory limitations prior to its use.

1 Scope

This document specifies a method to provide a relative measure for evaluating the degree of size

degradation and degree of metallization of iron ores, when reduced under conditions resembling those

prevailing in shaft direct-reduction processes.

This document is applicable to lump ores and hot-bonded pellets.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 2597-1, Iron ores — Determination of total iron content — Part 1: Titrimetric method after tin(II)

chloride reduction

ISO 2597-2, Iron ores — Determination of total iron content — Part 2: Titrimetric methods after

titanium(III) chloride reduction

ISO 3082, Iron ores — Sampling and sample preparation procedures

ISO 3310-1, Test sieves — Technical requirements and testing — Part 1: Test sieves of metal wire cloth

ISO 3310-2, Test sieves — Technical requirements and testing — Part 2: Test sieves of perforated metal

plate

ISO 5416, Direct reduced iron — Determination of metallic iron — Bromine-methanol titrimetric method

ISO 16878, Iron ores — Determination of metallic iron content — Iron(III) chloride titrimetric method

ISO 11323, Iron ore and direct reduced iron — Vocabulary

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 11323 apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

4 Principle

The test portion is isothermally reduced in a rotating tube bed, at 760 °C, using a reducing gas

consisting of H , CO, CO and CH , for 300 min. The reduced product is sieved with a sieve having square

2 2 4

openings of 3,15 mm. Then, it is analysed for total iron and metallic iron. The reduction-disintegration

index is calculated as the mass percentage of material less than 3,15 mm. The degree of metallization is

calculated from the chemical analysis results.

5 Sampling, sample preparation, and preparation of test portions

5.1 Sampling and sample preparation

Sampling of a lot and preparation of a test sample shall be in accordance with ISO 3082.

The size ranges for pellets shall be 50 % – 16,0 mm + 12,5 mm and 50 % – 12,5 mm + 10,0 mm.

The size ranges for lump ores shall be 50 % – 20,0 mm + 16,0 mm and 50 % – 16,0 mm + 10,0 mm.

A test sample of at least 2,0 kg, on a dry basis, of the sized material shall be obtained.

Oven-dry the test sample to constant mass at 105 °C ± 5 °C and cool it to room temperature before

preparation of the test portions.

NOTE Constant mass is achieved when the difference in mass between two subsequent measurements

becomes less than 0,05 % of the initial mass of the test sample.

5.2 Preparation of test portion

Collect each test portion by taking ore particles at random.

NOTE Manual methods of division recommended in ISO 3082, such as riffling, can be applied to obtain the

test portions.

At least four test portions, each of approximately 500 g (±the mass of 1 particle), shall be prepared from

the test sample.

Weigh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.