ISO 26867:2009

(Main)Road vehicles — Brake lining friction materials — Friction behaviour assessment for automotive brake systems

Road vehicles — Brake lining friction materials — Friction behaviour assessment for automotive brake systems

ISO 26867:2009 describes a test procedure for assessing the influence of pressure, temperature, and linear speed on the coefficient of friction of a given friction material in combination with a specific mating component (rotor or drum). ISO 26867:2009 is intended for use when comparing friction materials under the same conditions, or when controlling friction behaviour against a specification or certain performance limits. In order to take into account the different types of dynamometer cooling systems and to ensure repeatable temperature increments, the brake temperature is the control item during the fade sections. The types of brakes and discs used will vary according to individual projects. Production verification testing can use the results from this test in conjunction with a statistical process control system as part of a quality assurance plan. The specific project or programme will detail the applicable limits and assessment criteria. ISO 26867:2009 also allows for additional sections and brake applications that can prove useful during product development testing.

Véhicules routiers — Matériaux de friction pour garnitures de freins — Évaluation du comportement au frottement pour les systèmes de freinage automobiles

General Information

Standards Content (Sample)

DRAFT INTERNATIONAL STANDARD ISO/DIS 26867

ISO/TC 22/SC 2 Secretariat: AFNOR

Voting begins on: Voting terminates on:

2008-02-22 2008-07-22

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION • МЕЖДУНАРОДНАЯ ОРГАНИЗАЦИЯ ПО СТАНДАРТИЗАЦИИ • ORGANISATION INTERNATIONALE DE NORMALISATION

Road vehicles — Brake lining friction materials — Friction

behaviour assessment for automative brake systems

Véhicules routiers — Matériaux de friction pour garnitures de freins — Évaluation du comportement en friction

pour les systèmes de freinage automatiques

ICS 43.040.40

In accordance with the provisions of Council Resolution 15/1993 this document is circulated in

the English language only.

Conformément aux dispositions de la Résolution du Conseil 15/1993, ce document est distribué

en version anglaise seulement.

To expedite distribution, this document is circulated as received from the committee secretariat.

ISO Central Secretariat work of editing and text composition will be undertaken at publication

stage.

Pour accélérer la distribution, le présent document est distribué tel qu'il est parvenu du

secrétariat du comité. Le travail de rédaction et de composition de texte sera effectué au

Secrétariat central de l'ISO au stade de publication.

THIS DOCUMENT IS A DRAFT CIRCULATED FOR COMMENT AND APPROVAL. IT IS THEREFORE SUBJECT TO CHANGE AND MAY NOT BE

REFERRED TO AS AN INTERNATIONAL STANDARD UNTIL PUBLISHED AS SUCH.

IN ADDITION TO THEIR EVALUATION AS BEING ACCEPTABLE FOR INDUSTRIAL, TECHNOLOGICAL, COMMERCIAL AND USER PURPOSES, DRAFT

INTERNATIONAL STANDARDS MAY ON OCCASION HAVE TO BE CONSIDERED IN THE LIGHT OF THEIR POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN NATIONAL REGULATIONS.

RECIPIENTS OF THIS DRAFT ARE INVITED TO SUBMIT, WITH THEIR COMMENTS, NOTIFICATION OF ANY RELEVANT PATENT RIGHTS OF WHICH

THEY ARE AWARE AND TO PROVIDE SUPPORTING DOCUMENTATION.

©

International Organization for Standardization, 2008

ISO/DIS 26867

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall

not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the

unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

Copyright notice

This ISO document is a Draft International Standard and is copyright-protected by ISO. Except as permitted

under the applicable laws of the user's country, neither this ISO draft nor any extract from it may be

reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic, photocopying,

recording or otherwise, without prior written permission being secured.

Requests for permission to reproduce should be addressed to either ISO at the address below or ISO's

member body in the country of the requester.

ISO copyright office

Case postale 56 CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Reproduction may be subject to royalty payments or a licensing agreement.

Violators may be prosecuted.

©

ii ISO 2008 – All rights reserved

ISO/DIS 26867

Contents Page

1 Scope and field of application .1

2 Normative references.1

3 Symbols and abbreviated terms .1

4 Terms and definitions .2

5 Test conditions and preparation.5

5.1 Inertia for the front axle .5

5.2 Inertia for the rear axle.5

5.3 Test wheel load.5

5.4 Pressure ramp rate.6

5.5 Maximum pressure.6

5.6 Pressure level with no power assist.6

5.7 Sampling rate.6

5.8 Initial brake temperature.6

5.9 Brake warm-up.6

5.10 Temperature measurement .6

5.11 Brake fluid displacement measurement .6

5.12 Cooling air conditions.6

5.13 Cooling air velocity or volume .7

5.14 Conditioning settings for temperature and absolute humidity (humidity ratio).7

5.15 Dynamometer rotational speed between brake applications .7

5.16 Orientation of brake setup.7

5.17 Direction of air with regard to brake setup.7

5.18 Brake cooling rate .7

5.19 Wear measurement .7

5.20 Lateral run-out .7

5.21 Rotor or drum conditions .7

5.22 Fade sections.8

5.23 Data collection.9

6 Test procedures.9

6.1 Test procedure for product monitoring with no optional brake applications.9

6.2 Test procedure for product development with additional brake applications.10

7 Test report.12

7.1 Graphical report.12

7.2 Tabular data for each brake application .12

7.3 Wear measurements .13

7.4 Test conditions .13

7.5 Cooling air conditions.13

7.6 Brake cooling rate .13

7.7 Friction values .13

7.8 Statistical analysis .13

Annex A (informative) Vehicle and test parameters (per clause 5) .14

Annex B (informative) Sample report for disc brakes.15

B.1 graphical summaries.15

B.1.1 constant deceleration or pressure sections, graph instantaneous values versus stop or snub

number.15

B.1.2 Burnish section, graph snubs 2, 15, and 30. .15

B.1.3 Average by distance friction marker, include a marker for the average by distance friction for

all the stops or snubs graphed. .15

ISO/DIS 26867

Annex C (informative) Histograms for instantaneous friction values (per clauses 7.1.3 and 7.1.4) . 17

Annex D (informative) Reference calculations for cooling air speed and flow (per clause 5.13) . 19

D.1 Conversion between airflow and cooling air speed. 19

D.2 Calculation of cooling air speed passing over the brake. 20

iv © ISO 2008 – All rights reserved

ISO/DIS 26867

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 26867 was prepared by Technical Committee ISO/TC 22, Road vehicles, Subcommittee SC 2, Brake

systems and equipment.

ISO/DIS 26867

Introduction

The efforts of harmonization among different countries and technical groups have the modernization of friction

behaviour characterization of automotive brake systems applications as a top priority. This International

Standard is intended to replace previous friction evaluation testing based solely on drag brake applications,

which do not take into account real-life driving conditions, or vehicle specific parameters.

The varied condition under which the friction material is evaluated ensures a wide spectrum of data that is

critical during the various phases of product life such as product and manufacturing process development,

production validation, quality control, product auditing and field issues evaluation.

Use this International Standard in conjunction with other applicable standards or test procedures (ISO, SAE,

JASO, Federal Codes or regulations, and other project or company-specific testing programs) to fully assess a

friction material’s adequacy for use in a certain application, market or vehicle platform. This International

Standard does not include performance requirements related to stopping distance or braking force distribution,

under different vehicle conditions of speed, temperature, tire-to-road adhesion, loads, and operating

conditions of the braking system as indicated on Federal Codes or Regulations.

This International Standard is intended as a friction evaluation inertia-dynamometer test procedure to replace

previous test protocols that depend solely upon drag applications. This Standard supports the friction

assessment during the life cycle of a friction material.

Friction evaluation and characterization by performing drag applications, which were once a valid replacement

for sample and scale testing, have now proven a limited approach. Drag applications do not correlate with

real-world driving conditions, brake system characteristics, or vehicle dynamics. Lining transfer layer

properties,

...

INTERNATIONAL ISO

STANDARD 26867

First edition

2009-07-01

Road vehicles — Brake lining friction

materials — Friction behaviour

assessment for automotive brake

systems

Véhicules routiers — Matériaux de friction pour garnitures de freins —

Évaluation du comportement au frottement pour les systèmes de

freinage automobiles

Reference number

©

ISO 2009

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2009

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2009 – All rights reserved

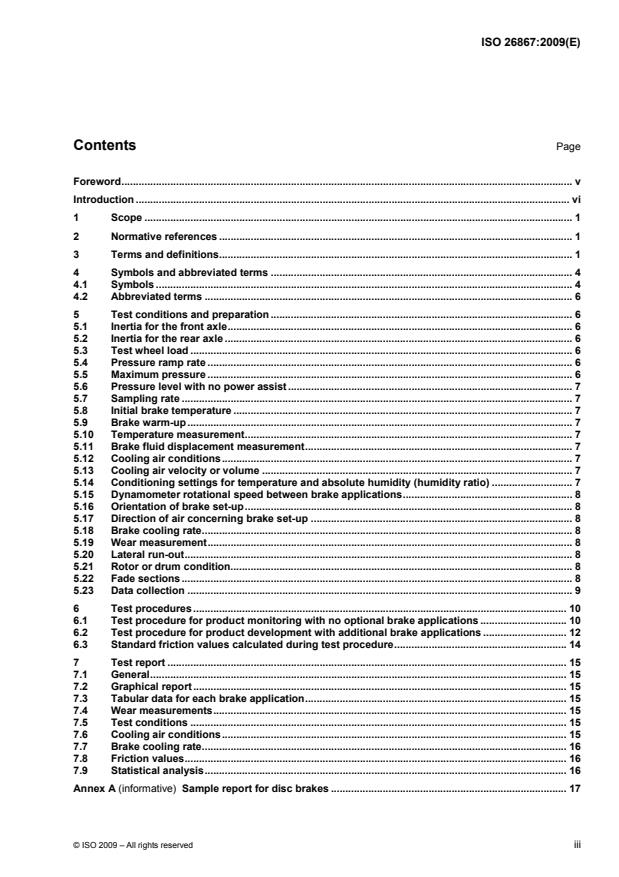

Contents Page

Foreword. v

Introduction . vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions. 1

4 Symbols and abbreviated terms . 4

4.1 Symbols . 4

4.2 Abbreviated terms . 6

5 Test conditions and preparation . 6

5.1 Inertia for the front axle. 6

5.2 Inertia for the rear axle . 6

5.3 Test wheel load . 6

5.4 Pressure ramp rate . 6

5.5 Maximum pressure . 6

5.6 Pressure level with no power assist. 7

5.7 Sampling rate . 7

5.8 Initial brake temperature . 7

5.9 Brake warm-up. 7

5.10 Temperature measurement. 7

5.11 Brake fluid displacement measurement. 7

5.12 Cooling air conditions. 7

5.13 Cooling air velocity or volume . 7

5.14 Conditioning settings for temperature and absolute humidity (humidity ratio) . 7

5.15 Dynamometer rotational speed between brake applications. 8

5.16 Orientation of brake set-up. 8

5.17 Direction of air concerning brake set-up . 8

5.18 Brake cooling rate. 8

5.19 Wear measurement. 8

5.20 Lateral run-out. 8

5.21 Rotor or drum condition. 8

5.22 Fade sections . 8

5.23 Data collection . 9

6 Test procedures . 10

6.1 Test procedure for product monitoring with no optional brake applications . 10

6.2 Test procedure for product development with additional brake applications . 12

6.3 Standard friction values calculated during test procedure. 14

7 Test report . 15

7.1 General. 15

7.2 Graphical report. 15

7.3 Tabular data for each brake application. 15

7.4 Wear measurements. 15

7.5 Test conditions . 15

7.6 Cooling air conditions. 15

7.7 Brake cooling rate. 16

7.8 Friction values. 16

7.9 Statistical analysis. 16

Annex A (informative) Sample report for disc brakes . 17

Annex B (informative) Histograms for instantaneous friction values. 20

Annex C (informative) Reference calculations for cooling air speed and flow. 22

Bibliography . 24

iv © ISO 2009 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 26867 was prepared by Technical Committee ISO/TC 22, Road vehicles, Subcommittee SC 2, Braking

systems and equipment.

Introduction

In the process of harmonizing automotive brake system applications, the modernization of friction behaviour

characterization is a top priority. This International Standard is intended to replace previous friction evaluation

test procedures based solely on drag brake applications, which do not take into account real-life driving

conditions or vehicle specific parameters.

The varied conditions under which the friction material is evaluated ensures a wide spectrum of data, which is

critical during the various phases of product life, such as product and manufacturing process development,

production validation, quality control, product auditing and field issues evaluation.

This International Standard is intended to be used in conjunction with other applicable standards or test

procedures (ISO, SAE, JIS/JASO, Federal Codes or Regulations, and other project or company-specific

testing programmes) to fully assess the adequacy of a friction material for use in a certain application, market

or vehicle platform. This International Standard does not include performance requirements related to

stopping distance or braking force distribution, under different vehicle conditions of speed, temperature, tyre-

to-road adhesion, loads and operating conditions of the braking system, as indicated in Federal Codes or

Regulations.

This International Standard is intended as a friction evaluation inertia-dynamometer test procedure to replace

previous test protocols that depend solely upon drag applications. This International Standard supports the

friction assessment during the life cycle of a friction material.

Friction evaluation and characterization by performing drag applications, which were once a valid replacement

for sample and scale testing, have now proven a limited approach. Drag applications do not correlate with

real-world driving conditions, brake system characteristics or vehicle dynamics. The chemistry and structure of

the transfer layers developed at the surface of the friction couple (friction lining and mating rotor or drum) and

the resulting coefficient of friction varies as a function of changing characteristics, e.g. sliding speed, surface

and bulk temperatures, braking pressure, braking energy and surface topology. During any given brake

application, the braking energy varies as a result of the mass distribution and dynamic mass transfer on the

vehicle. This is directly related to the vehicle's wheelbase, centre of gravity and vehicle height, which in itself

can directly influence the friction material behaviour. The same brake lining or part number, when used on

different vehicles, can perform differently depending upon its load, velocity, operating temperature, application

force and work history. Modern testing equipment enables friction formulators, process designers, applications

engineers and manufacturing personnel to obtain a wide and detailed characterization on the different levels

of friction witnessed by the brake lining or pad during various brake conditions.

This International Standard is designed to evaluate the friction behaviour under a wide array of driving speeds,

brake temperatures, brake pressure and deceleration levels. This new procedure provides the following

benefits:

⎯ a standard method for determining friction characteristics during early screening, benchmarking;

development or production monitoring;

⎯ the use of average by distance torque and pressure calculations;

⎯ instantaneous friction statistics;

⎯ an estimation of stopping distance using mean fully developed deceleration;

⎯ controlled and recorded environmental conditions.

vi © ISO 2009 – All rights reserved

INTERNATIONAL STANDARD ISO

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.