ISO 5208:2015

(Main)Industrial valves — Pressure testing of metallic valves

Industrial valves — Pressure testing of metallic valves

ISO 5208:2015 specifies examinations and tests that a valve manufacturer needs to act upon in order to establish the integrity of the pressure boundary of an industrial metallic valve and to verify the degree of valve closure tightness and the structural adequacy of its closure mechanism. This International Standard is intended to be applied in conjunction with the specific requirements of a valve product standard to the extent cited by the product standard as a normative reference. Where requirements of a product standard differ from those given in this International Standard, the requirements of the product standard apply. ISO 5208:2015 is not applicable to the safety aspects of pressure testing.

Robinetterie industrielle — Essais sous pression des appareils de robinetterie métalliques

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 5208

Fourth edition

2015-06-15

Industrial valves — Pressure testing of

metallic valves

Robinetterie industrielle — Essais sous pression des appareils de

robinetterie métalliques

Reference number

©

ISO 2015

© ISO 2015, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2015 – All rights reserved

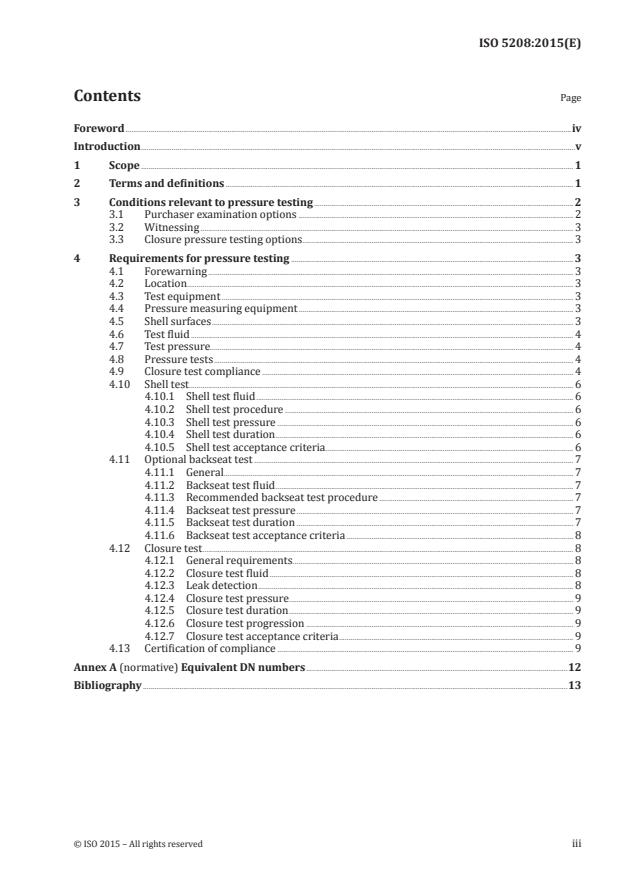

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Terms and definitions . 1

3 Conditions relevant to pressure testing . 2

3.1 Purchaser examination options . 2

3.2 Witnessing . 3

3.3 Closure pressure testing options . 3

4 Requirements for pressure testing . 3

4.1 Forewarning . 3

4.2 Location . 3

4.3 Test equipment . 3

4.4 Pressure measuring equipment . 3

4.5 Shell surfaces . 3

4.6 Test fluid . 4

4.7 Test pressure. 4

4.8 Pressure tests . 4

4.9 Closure test compliance . 4

4.10 Shell test. 6

4.10.1 Shell test fluid . 6

4.10.2 Shell test procedure . 6

4.10.3 Shell test pressure . 6

4.10.4 Shell test duration . 6

4.10.5 Shell test acceptance criteria . 6

4.11 Optional backseat test . 7

4.11.1 General. 7

4.11.2 Backseat test fluid . 7

4.11.3 Recommended backseat test procedure . 7

4.11.4 Backseat test pressure . 7

4.11.5 Backseat test duration . 7

4.11.6 Backseat test acceptance criteria . 8

4.12 Closure test . 8

4.12.1 General requirements . 8

4.12.2 Closure test fluid . 8

4.12.3 Leak detection . 8

4.12.4 Closure test pressure. 9

4.12.5 Closure test duration . 9

4.12.6 Closure test progression . 9

4.12.7 Closure test acceptance criteria . 9

4.13 Certification of compliance . 9

Annex A (normative) Equivalent DN numbers .12

Bibliography .13

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 153, Valves.

This fourth edition cancels and replaces the third edition (ISO 5208:2008), which has been technically

revised including the following changes:

— a new definition 2.12 of visually detectable leakage was added;

— Table 1 has been updated by differencing concentric and eccentric butterfly valves and by adding an

optional high pressure closure test with gas;

— 4.12.4.1 a) has been updated to take into account nominal pressures PN 6 and lower.

iv © ISO 2015 – All rights reserved

Introduction

The purpose of this International Standard is the establishment of basic requirements and practices for

pressure testing valves of various configurations that are used in general purpose, power generation,

petroleum, and petrochemical or allied industry applications. The intent is to provide a consistent set

of procedural requirements and acceptance criteria that can be considered in conjunction with valve

specific standards appropriate for specific applications. Account has been taken of the valve testing

requirement needs of EN 12266 and API 598 with requirements referenced for PN designated valves for

the former and Class designated valves for the latter.

INTERNATIONAL STANDARD ISO 5208:2015(E)

Industrial valves — Pressure testing of metallic valves

WARNING — Persons using this International Standard should be familiar with normal testing

practice. This International Standard does not purport to address all of the safety issues, if

any, associated with its use. It is the responsibility of the user to establish appropriate safety

and health practices and to ensure compliance with any national regulatory requirements in

particular, when using high pressure gas for testing.

1 Scope

This International Standard specifies examinations and tests that a valve manufacturer needs to act

upon in order to establish the integrity of the pressure boundary of an industrial metallic valve and

to verify the degree of valve closure tightness and the structural adequacy of its closure mechanism.

This International Standard is intended to be applied in conjunction with the specific requirements

of a valve product standard to the extent cited by the product standard as a normative reference.

Where requirements of a product standard differ from those given in this International Standard, the

requirements of the product standard apply.

This International Standard is not applicable to the safety aspects of pressure testing.

2 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

2.1

shell test

test at a pressure in excess of the cold working pressure (2.9) rating of a valve for the purpose of validating

the soundness and strength of the valve pressure containing and retaining structures

Note 1 to entry: These structures include valve-actuating mechanisms that have a direct connection to the valve

internals subject to fluid test pressure within the valve proper.

2.2

closure test

pressure test for the purpose of validating leakage through a valve’s closure mechanism

2.3

test pressure

internal pressure (gauge), expressed in bar to which the valve under test is subjected

Note 1 to entry: Unless otherwise noted, gauge pressure is used throughout this International Standard.

Note 2 to entry: 1 bar = 10 Pa.

2.4

test fluid

pressurized liquid or gas used to test a valve

2.5

test fluid temperature

temperature of the test fluid, > 5 °C and ≤ 40 °C

2.6

resilient seats

broad categ

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.