ISO 22183:2023

(Main)Plastics — Validation of force-time curves obtained from high-speed tensile tests

Plastics — Validation of force-time curves obtained from high-speed tensile tests

This document specifies procedures for validation of high-speed tensile test data. It specifies a method to determine the spectrum of the natural oscillation frequencies of the force transducer and grip configuration of the high-speed tensile test equipment. The lowest significant frequency is used for the validation. This validation procedure only applies to force measurement systems used in high-speed tensile testing machines showing a level of resonance influence that could be critical to the obtained result. Once the relevant frequencies of the system and the anticipated strain for the given material are known, this method allows to calculate the theoretical maximum allowed test speed too.

Plastiques — Validation des courbes force-temps obtenues à partir d'essais de traction à grande vitesse

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 22183

First edition

2023-05

Plastics — Validation of force-time

curves obtained from high-speed

tensile tests

Plastiques — Validation des courbes force-temps obtenues à partir

d'essais de traction à grande vitesse

Reference number

© ISO 2023

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

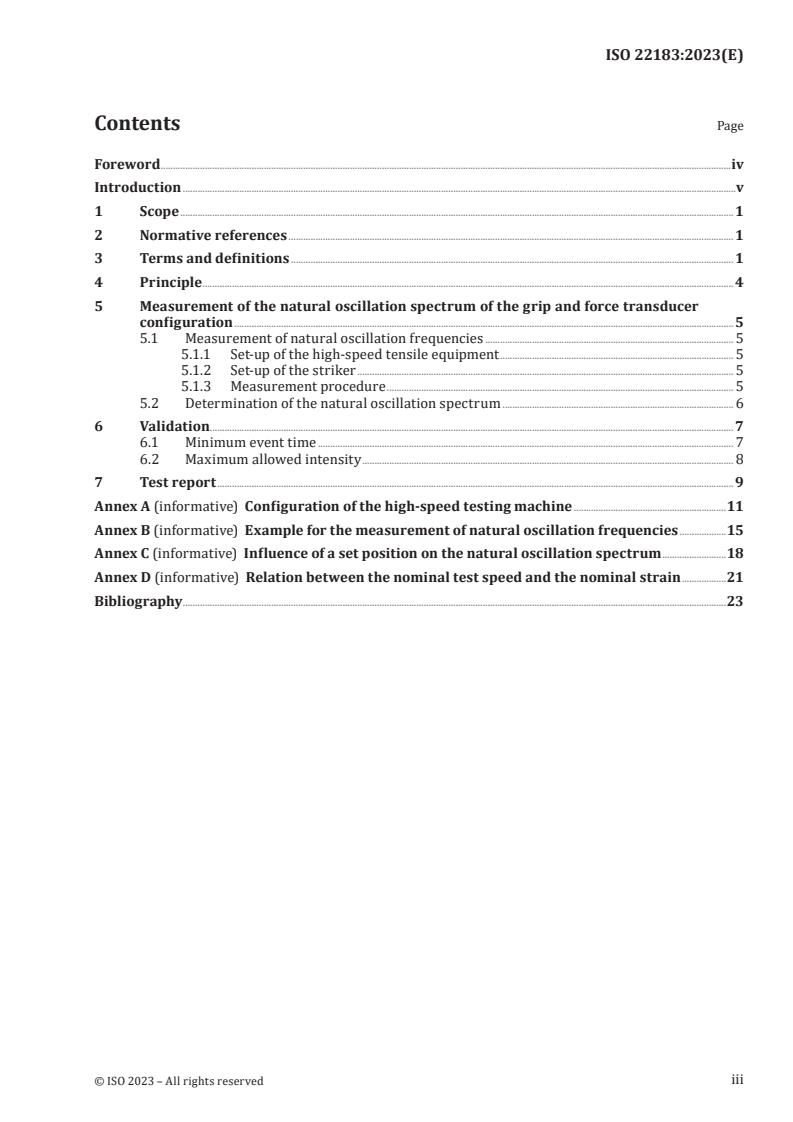

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Principle . 4

5 Measurement of the natural oscillation spectrum of the grip and force transducer

configuration .5

5.1 Measurement of natural oscillation frequencies . 5

5.1.1 Set-up of the high-speed tensile equipment . 5

5.1.2 Set-up of the striker . 5

5.1.3 Measurement procedure . 5

5.2 Determination of the natural oscillation spectrum . 6

6 Validation . . 7

6.1 Minimum event time . 7

6.2 Maximum allowed intensity . 8

7 Test report . 9

Annex A (informative) Configuration of the high-speed testing machine .11

Annex B (informative) Example for the measurement of natural oscillation frequencies .15

Annex C (informative) Influence of a set position on the natural oscillation spectrum .18

Annex D (informative) Relation between the nominal test speed and the nominal strain .21

Bibliography .23

iii

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO document should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use

of (a) patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed

patent rights in respect thereof. As of the date of publication of this document, ISO had received notice of

(a) patent(s) which may be required to implement this document. However, implementers are cautioned

that this may not represent the latest information, which may be obtained from the patent database

available at www.iso.org/patents. ISO shall not be held responsible for identifying any or all such patent

rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 61, Plastics, Subcommittee SC 2,

Mechanical properties.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

iv

Introduction

The method described in this document provides criteria for the validation of measurement curves

obtained from high-speed tensile tests.

Force, time, travel and strain measurement systems of high-speed tensile equipment are usually

calibrated in static mode. Dynamic effects, occurring at such tests, need to be addressed and limits or

ranges of use for the obtained assessment parameters need to be set in order to allow the validation of

the obtained measurement curves.

This document contains a method to measure the spectrum of the natural mechanical frequencies of

the force transducer and grip arrangement, considering that these frequencies are the most important

limiting factor for the range of use of a high-speed tensile test equipment.

In addition, there are further parameters which may play a role for the dynamic quality of the

measurement curves, such as the data acquisition frequency, or oscillations generated in the machine

frame. These parameters should be carefully supervised, and measures need to be taken if such

problems occur in a significant way.

In case direct travel or strain measurement is used to generate stress-strain curves or to determine

nominal or local strain rates, further parameters, such as the synchronization between force, time and

strain channels, need to be supervised.

v

INTERNATIONAL STANDARD ISO 22183:2023(E)

Plastics — Validation of force-time curves obtained from

high-speed tensile tests

1 Scope

This document specifies procedures for validation of high-speed tensile test data. It specifies a method

to determine the spectrum of the natural oscillation frequencies of the force transducer and grip

configuration of the high-speed tensile test equipment.

The lowest significant frequency is used for the validation. This validation procedure only applies to

force measurement systems used in high-speed tensile testing machines showing a level of resonance

influence that could be critical to the obtained result. Once the relevant frequencies of the system and

the anticipated strain for the given material are known, this method allows to calculate the theoretical

maximum allowed test speed too.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1

unloaded region

time domain prior to the application of the load by the striker

Note 1 to entry: See Figure 1.

3.2

striking peak

first force peak generated by the striker hitting the grip

Note 1 to entry: See Figure 1.

3.3

residual oscillations region

oscillations triggered by the striker

Note 1 to entry: It represents the force on the time domain after the strike of the striker.

Note 2 to entry: See Figure 1.

Key

X time (ms)

Y force (N)

1 unloaded region

2 striking peak

3 residual oscillations region

Figure 1 — Typical force-time signal during the impact test

3.4

maximum force within the residual oscillations

F

r,max

maximum force – intended as absolute value – present in the residual oscillations, excluding the striking

peak

Note 1 to entry: It is expressed in Newtons (N).

3.5

maximum force in the unloaded state

F

u,max

maximum absolute force value in the unloaded region

Note 1 to entry: It is expressed in Newtons (N).

3.6

natural oscillation spectrum

frequency spectrum obtained as a result of a Fast Fourier Transform Analysis of the residual oscillations

region, normalized to the largest amplitude present

3.7

frequency

f

frequency of a relevant peak in the natural frequency spectrum

Note 1 to entry: It is expressed in kilohertz (kHz).

3.8

normalized intensity of the frequency

I

normalized intensity of frequency peak in the natural oscillation spectrum

3.9

lowest relevant frequency

f

low

frequency of the first relevant peak in the natural oscillation spectrum

Note 1 to entry: It is expressed in kilohertz (kHz).

3.10

event time

t

e

time from the start point of the force-time curve without unloaded region to the point of the relevant

event to be measured

Note 1 to entry: The relevant event is either the yield point, or the break point or any other defined point.

Note 2 to entry: It is expressed in milliseconds (ms).

3.11

threshold number of waves in the event

w

N,th

minimum number of waves of the relevant lowest frequency within the event time

3.12

gripping distance

L

initial length of the part of the specimen between the grips

Note 1 to entry: It is expressed in millimetres (mm).

Note 2 to entry: See Annex A.

3.13

grip displacement

ΔL

displacement of the grip pulled to tensile direction of specimens from the beginning of the test

Note 1 to entry: It is expressed in millimetres (mm).

Note 2 to entry: Most of the loading mechanics of the high-speed tensile test device have the one side pulled and

the other end fixed, as shown in Annex A.

3.14

nominal strain

ε

t

grip displacement divided by the initial gripping distance

Note 1 to entry: It is expressed as a dimensionless ratio, or as a percentage (%).

3.15

nominal test speed

v

rate of separation of the gripping jaws

Note 1 to entry: It is expressed in metres per second (m/s).

3.16

maximum force

F

max

maximum force observed in the whole force-time curve during the high-speed tensile test

Note 1 to entry: See Figure 2.

Note 2 to entry: It is expressed in Newtons (N).

3.17

maximum amplitude of oscillations

ΔF

a,max

largest peak-to-peak amplitude of oscillations, observed over a small portion of the curve during the

high-speed tensile test, ignoring single spikes of electronic noise

Note 1 to entry: See Figure 2.

Note 2 to entry: It is expressed in Newtons (N).

Key

X

time (ms )

Y force (N)

1 event time (ms)

t

e

2 maximum force (N)

F

max

3 maximum amplitude of oscillations (N)

ΔF

am, ax

Figure 2 — Typical force-time curve during tensile test at high speed

4 Principle

The principle of this document is based on the following two acceptance criteria:

1) The measurement of the natural oscillations of grip and force transducer configuration (see 6.1)

The natural oscillation frequencies of the force transducer and grip arrangement in the testing

instrument are measured after a defined impact. These frequencies are analysed by means of a Fast

Fourier Transform (FFT) and presented by their intensity over the relevant frequency range. The

highest intensity observed is used to calculate a normalized intensity. The lowest frequency of a

relevant normalized intensity will be used to establish the validation criterion.

2) The maximum allowed inte

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.