ISO/TR 14749:2016

(Main)Natural gas — Online gas chromatograph for upstream area

Natural gas — Online gas chromatograph for upstream area

ISO/TS 14749:2016 concerns the determination of hydrocarbon components up to C7+ in natural gas in upstream petroleum industry, which describes the principle of operation of GC and provides guidelines for selection, evaluation, and factors impacting upon its performance such as sample probe, sample conditioning, installation, operation and troubleshooting.

Gaz naturels — Chromatographe en phase gazeuse en ligne pour zone amont

General Information

Relations

Standards Content (Sample)

TECHNICAL ISO/TR

REPORT 14749

First edition

Natural gas — Online gas

chromatograph for upstream area

Gaz naturels — Chromatographe en phase gazeuse en ligne pour

zone amont

PROOF/ÉPREUVE

Reference number

©

ISO 2016

© ISO 2016, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2016 – All rights reserved

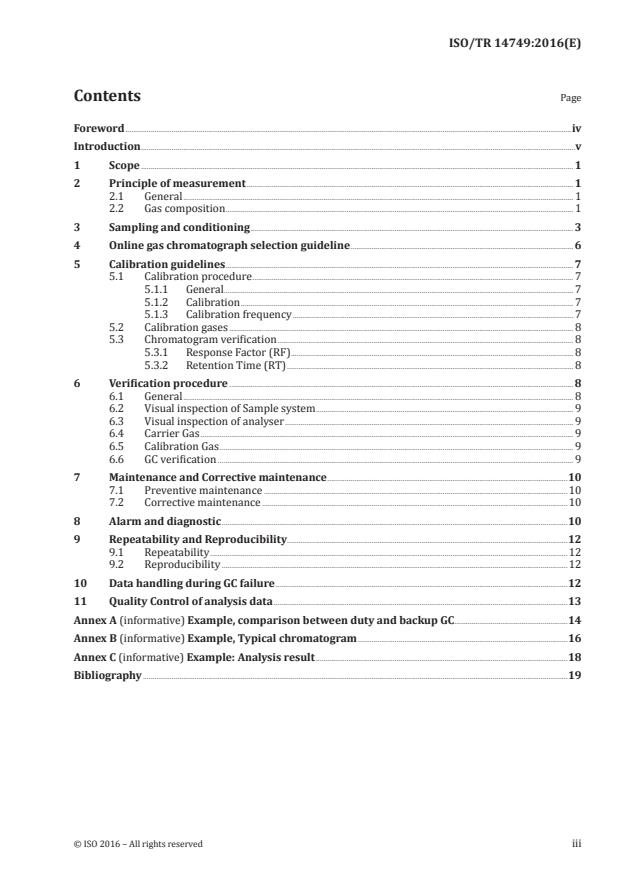

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Principle of measurement . 1

2.1 General . 1

2.2 Gas composition . 1

3 Sampling and conditioning . 3

4 Online gas chromatograph selection guideline . 6

5 Calibration guidelines . 7

5.1 Calibration procedure . 7

5.1.1 General. 7

5.1.2 Calibration . 7

5.1.3 Calibration frequency . 7

5.2 Calibration gases . 8

5.3 Chromatogram verification . 8

5.3.1 Response Factor (RF) . 8

5.3.2 Retention Time (RT) . 8

6 Verification procedure . 8

6.1 General . 8

6.2 Visual inspection of Sample system . 9

6.3 Visual inspection of analyser . 9

6.4 Carrier Gas . 9

6.5 Calibration Gas . 9

6.6 GC verification . 9

7 Maintenance and Corrective maintenance .10

7.1 Preventive maintenance .10

7.2 Corrective maintenance .10

8 Alarm and diagnostic .10

9 Repeatability and Reproducibility .12

9.1 Repeatability .12

9.2 Reproducibility .12

10 Data handling during GC failure .12

11 Quality Control of analysis data .13

Annex A (informative) Example, comparison between duty and backup GC .14

Annex B (informative) Example, Typical chromatogram .16

Annex C (informative) Example: Analysis result .19

Bibliography .20

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2. www.iso.org/directives

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received. www.iso.org/patents

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical

Barriers to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 193, Natural gas, Subcommittee SC 3,

Upstream area.

iv PROOF/ÉPREUVE © ISO 2016 – All rights reserved

Introduction

Online Gas Chromatograph (GC) is widely used to determine hydrocarbon components in natural gas

because of its “Real time” measurement and ease of use. It has become a powerful tool for both custody

transfer and upstream process gas monitoring. Especially for the custody transfer which the calorific

value and others gas properties such as, relative density, compressibility factor, etc. are needed for

energy determination. Therefore, accuracy and reliability of the equipment are crucial.

With proper maintenance and handling, GC can provide an accurate result with a minimum manpower

as it analyzes and provides results continuously. With technology today, the unit can do auto-calibration,

alarm setting, diagnostic, troubleshooting and configuring through Human Machine Interface (HMI).

Its outputs can be linked directly with Flow computer, Distributed Control System (DCS) or any remote

personal computer (PC).

The Natural Gas in upstream petroleum industry is normally wet. Then this Technical Report provides

recommended application to handling GC focus on design, selection, operation, maintenance and

verification of GC and its peripheral. The purpose is to provide the whole process to proper handling

the GC until getting the accurate and reliable results. It is also included the sampling system to get the

representative sample, data verification, alarm, diagnostic and troubleshooting including how to deal

with the data in case of being used for custody transfer purpose. Some acceptance criteria are also

identified in this paper based on our historical record and performance of the equipment.

TECHNICAL REPORT ISO/TR 14749:2016(E)

Natural gas — Online gas chromatograph for upstream area

1 Scope

This Technical Report concerns the determination of hydrocarbon components up to C7+ in natural

gas in upstream petroleum industry, which describes the principle of operation of GC and provides

guidelines for selection, evaluation, and factors impacting upon its performance such as sample probe,

sample conditioning, installation, operation and troubleshooting.

2 Principle of measurement

2.1 General

The GC is a technique for separating and analysing compounds that can be vaporized without

decomposition in a continuous and automatic manner of sample injection, separation, data integration

and reporting. A precise volume of sample gas is injected into the column which contains a stationary

phase (packing) that is either an active solid (adsorption partition) or an inert solid support that is

coated with a liquid phase (absorption partitioning). The gas is moved through the column by means

of a mobile phase (carrier gas). Selective retention of the components of the sample takes place in

the column and causes each component to move through the column at a different rate. This action

separates the sample into its gaseous constituents.

A detector detects the elution of component from the column and produces electrical outputs

proportional to the concentration of each component. Output from the detector are amplified in the

electronics, then transmitted to the controller for further processing.

2.2 Gas composition

Natural gas is composed primarily of methane with smaller amounts of higher hydrocarbons and of

non combustible gases. Major, minor and trace components are as indicated in Tables 1, 2 and 3:

Table 1 — Major components

Component Units

Methane mole %

Ethane mole %

Propane mole %

Butanes mole %

Pentanes mole %

Hexanes mole %

Heptanes plus mole %

Nitrogen mole %

Carbon dioxide mole %

Table 2 — Minor component

Component Units

Hydrogen mole %

Oxygen mole %

Carbon monoxide mole %

Helium mole %

Table 3 — Trace component

Component Units

Hydrogen sulfide mg/m

Mercaptan sulfur mg/m

Dialkyl (di) sulfide mg/m

Carbonyl sulfide mg/m

Total sulfur mg/m

Figure 1 — Online Gas Chromatograph Functional Block Diagram

2 PROOF/ÉPREUVE © ISO 2016 – All rights reserved

Figure 2 — Online Gas Chromatograph Functional Block Diagram

Output from the controller is normally linked to flow computer, DCS, remote personal computer (PC) or

a printer. Connection

...

TECHNICAL ISO/TR

REPORT 14749

First edition

2016-05-15

Natural gas — Online gas

chromatograph for upstream area

Gaz naturels — Chromatographe en phase gazeuse en ligne pour

zone amont

Reference number

©

ISO 2016

© ISO 2016, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2016 – All rights reserved

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Principle of measurement . 1

2.1 General . 1

2.2 Gas composition . 1

3 Sampling and conditioning . 3

4 Online gas chromatograph selection guideline . 6

5 Calibration guidelines . 7

5.1 Calibration procedure . 7

5.1.1 General. 7

5.1.2 Calibration . 7

5.1.3 Calibration frequency . 7

5.2 Calibration gases . 8

5.3 Chromatogram verification . 8

5.3.1 Response Factor (RF) . 8

5.3.2 Retention Time (RT) . 8

6 Verification procedure . 8

6.1 General . 8

6.2 Visual inspection of Sample system . 9

6.3 Visual inspection of analyser . 9

6.4 Carrier Gas . 9

6.5 Calibration Gas . 9

6.6 GC verification . 9

7 Maintenance and Corrective maintenance .10

7.1 Preventive maintenance .10

7.2 Corrective maintenance .10

8 Alarm and diagnostic .10

9 Repeatability and Reproducibility .12

9.1 Repeatability .12

9.2 Reproducibility .12

10 Data handling during GC failure .12

11 Quality Control of analysis data .13

Annex A (informative) Example, comparison between duty and backup GC .14

Annex B (informative) Example, Typical chromatogram .16

Annex C (informative) Example: Analysis result .18

Bibliography .19

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2. www.iso.org/directives

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received. www.iso.org/patents

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical

Barriers to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 193, Natural gas, Subcommittee SC 3,

Upstream area.

iv © ISO 2016 – All rights reserved

Introduction

Online Gas Chromatograph (GC) is widely used to determine hydrocarbon components in natural gas

because of its “Real time” measurement and ease of use. It has become a powerful tool for both custody

transfer and upstream process gas monitoring. Especially for the custody transfer which the calorific

value and others gas properties such as, relative density, compressibility factor, etc. are needed for

energy determination. Therefore, accuracy and reliability of the equipment are crucial.

With proper maintenance and handling, GC can provide an accurate result with a minimum manpower

as it analyzes and provides results continuously. With technology today, the unit can do auto-calibration,

alarm setting, diagnostic, troubleshooting and configuring through Human Machine Interface (HMI).

Its outputs can be linked directly with Flow computer, Distributed Control System (DCS) or any remote

personal computer (PC).

The Natural Gas in upstream petroleum industry is normally wet. Then this Technical Report provides

recommended application to handling GC focus on design, selection, operation, maintenance and

verification of GC and its peripheral. The purpose is to provide the whole process to proper handling

the GC until getting the accurate and reliable results. It is also included the sampling system to get the

representative sample, data verification, alarm, diagnostic and troubleshooting including how to deal

with the data in case of being used for custody transfer purpose. Some acceptance criteria are also

identified in this paper based on our historical record and performance of the equipment.

TECHNICAL REPORT ISO/TR 14749:2016(E)

Natural gas — Online gas chromatograph for upstream area

1 Scope

This Technical Report concerns the determination of hydrocarbon components up to C7+ in natural

gas in upstream petroleum industry, which describes the principle of operation of GC and provides

guidelines for selection, evaluation, and factors impacting upon its performance such as sample probe,

sample conditioning, installation, operation and troubleshooting.

2 Principle of measurement

2.1 General

The GC is a technique for separating and analysing compounds that can be vaporized without

decomposition in a continuous and automatic manner of sample injection, separation, data integration

and reporting. A precise volume of sample gas is injected into the column which contains a stationary

phase (packing) that is either an active solid (adsorption partition) or an inert solid support that is

coated with a liquid phase (absorption partitioning). The gas is moved through the column by means

of a mobile phase (carrier gas). Selective retention of the components of the sample takes place in

the column and causes each component to move through the column at a different rate. This action

separates the sample into its gaseous constituents.

A detector detects the elution of component from the column and produces electrical outputs

proportional to the concentration of each component. Output from the detector are amplified in the

electronics, then transmitted to the controller for further processing.

2.2 Gas composition

Natural gas is composed primarily of methane with smaller amounts of higher hydrocarbons and of

non combustible gases. Major, minor and trace components are as indicated in Tables 1, 2 and 3:

Table 1 — Major components

Component Units

Methane mole %

Ethane mole %

Propane mole %

Butanes mole %

Pentanes mole %

Hexanes mole %

Heptanes plus mole %

Nitrogen mole %

Carbon dioxide mole %

Table 2 — Minor component

Component Units

Hydrogen mole %

Oxygen mole %

Carbon monoxide mole %

Helium mole %

Table 3 — Trace component

Component Units

Hydrogen sulfide mg/m

Mercaptan sulfur mg/m

Dialkyl (di) sulfide mg/m

Carbonyl sulfide mg/m

Total sulfur mg/m

Figure 1 — Online Gas Chromatograph Functional Block Diagram

2 © ISO 2016 – All rights reserved

Figure 2 — Online Gas Chromatograph Equipment Diagram

Output from the controller is normally linked to flow computer, DCS, remote personal computer (PC) or

a printer. Connection between the GC Controller and others can be accomplished via a direct seri

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.