ISO 8000-66:2021

(Main)Data quality — Part 66: Data quality management: Assessment indicators for data processing in manufacturing operations

Data quality — Part 66: Data quality management: Assessment indicators for data processing in manufacturing operations

This document specifies assessment indicators to support the assessment of organizational process maturity for data quality management in the context of manufacturing operations management as specified by IEC 62264‑1. The following are within scope of this document: — assessment indicators that are work products generated by data processing (as specified by ISO 8000‑61) and, thus, enable rating of process performance, a process attribute specified by ISO/IEC 33020; — the role played by each work product in the processes of manufacturing operations management; — the connection of each work product to the outcomes of the processes of manufacturing operations management. The following are outside the scope of this document: — assessment indicators for any of the other process attributes specified by ISO/IEC 33020; — methods or procedures to measure process capability.

Qualité des données — Partie 66: Gestion de la qualité des données : Indicateurs d'évaluation pour le traitement des données dans les opérations de fabrication

General Information

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 8000-66

First edition

2021-10

Data quality —

Part 66:

Data quality management: Assessment

indicators for data processing in

manufacturing operations

Reference number

© ISO 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

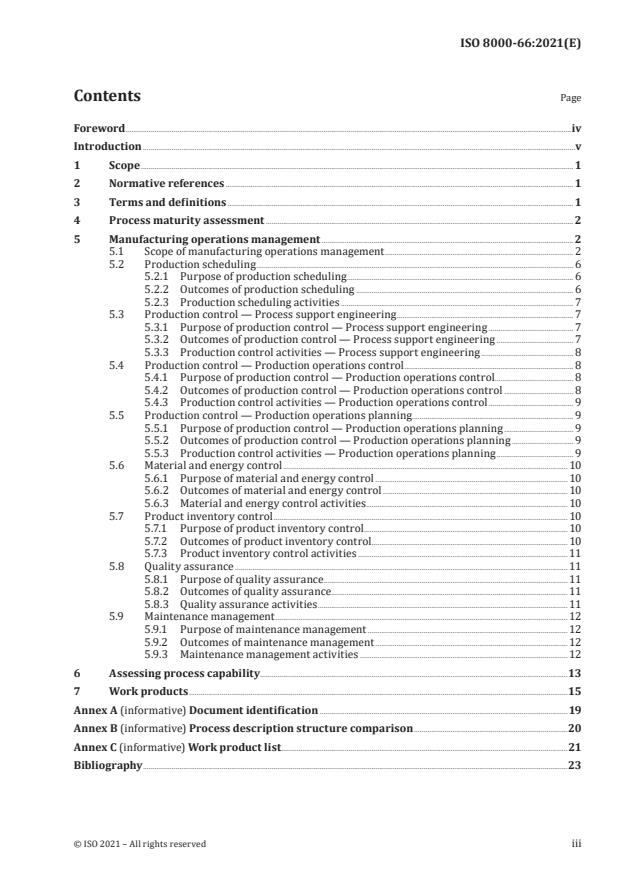

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Process maturity assessment . 2

5 Manufacturing operations management . 2

5.1 Scope of manufacturing operations management . 2

5.2 Production scheduling . 6

5.2.1 Purpose of production scheduling. 6

5.2.2 Outcomes of production scheduling . 6

5.2.3 Production scheduling activities . 7

5.3 Production control — Process support engineering . 7

5.3.1 Purpose of production control — Process support engineering . 7

5.3.2 Outcomes of production control — Process support engineering . 7

5.3.3 Production control activities — Process support engineering . 8

5.4 Production control — Production operations control . 8

5.4.1 Purpose of production control — Production operations control. 8

5.4.2 Outcomes of production control — Production operations control . 8

5.4.3 Production control activities — Production operations control . 9

5.5 Production control — Production operations planning. 9

5.5.1 Purpose of production control — Production operations planning . 9

5.5.2 Outcomes of production control — Production operations planning . 9

5.5.3 Production control activities — Production operations planning . 9

5.6 Material and energy control . 10

5.6.1 Purpose of material and energy control . 10

5.6.2 Outcomes of material and energy control . 10

5.6.3 Material and energy control activities. 10

5.7 Product inventory control . 10

5.7.1 Purpose of product inventory control . 10

5.7.2 Outcomes of product inventory control . 10

5.7.3 Product inventory control activities . 11

5.8 Quality assurance . 11

5.8.1 Purpose of quality assurance . 11

5.8.2 Outcomes of quality assurance. 11

5.8.3 Quality assurance activities . 11

5.9 Maintenance management . 12

5.9.1 Purpose of maintenance management .12

5.9.2 Outcomes of maintenance management .12

5.9.3 Maintenance management activities .12

6 Assessing process capability.13

7 Work products .15

Annex A (informative) Document identification .19

Annex B (informative) Process description structure comparison .20

Annex C (informative) Work product list .21

Bibliography .23

iii

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 184, Automation systems and integration,

Subcommittee SC 4, Industrial data.

A list of all parts in the ISO 8000 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

iv

Introduction

Digital data delivers value by enhancing all aspects of organizational performance, including:

— operational effectiveness and efficiency;

— safety;

— reputation with customers and the wider public;

— compliance with statutory regulations;

— consumer costs, revenues and stock prices.

The influence on performance originates from data being the formalized representation of information.

This information enables organizations to make reliable decisions. This decision making can be

performed by human beings directly and also by automated data processing including artificial

intelligence systems.

Through widespread adoption of digital computing and associated communication technologies,

organizations become dependent on digital data. This dependency amplifies the negative consequences

of the lack of quality in this data. These consequences are the decrease of organizational performance.

The biggest impact of digital data comes from two key factors:

— the data having a structure that reflects the nature of the subject matter;

— the data also being computer processable (machine readable) rather than just being for a person to

read and understand.

ISO 9000 explains that quality is not an abstract concept of absolute perfection. Quality is actually the

conformance of characteristics to requirements and, thus, any item of data can be of high quality for

one use but not for another use that has differing requirements.

EXAMPLE 1 When storing start times for meetings, a calendar application requires less precision than a

control system would for storing the times at which to activate a propulsion unit during a spaceflight.

The nature of digital data is fundamental to establishing requirements that are relevant to the specific

decisions that are made by each organization.

EXAMPLE 2 ISO/TS 8000-1 identifies that data has syntactic (format), semantic (meaning) and pragmatic

(usefulness) characteristics.

To support the delivery of high-quality data, the ISO 8000 series addresses:

— data governance, data quality management and maturity assessment;

EXAMPLE 3 ISO 8000-61 specifies a process reference model for data quality management.

— creating and applying requirements for data and information;

EXAMPLE 4 ISO 8000-110 specifies how to exchange characteristic data that is master data.

— monitoring and measuring data and information quality;

EXAMPLE 5 ISO 8000-8 specifies approaches to measuring data and information quality.

— improving data and, consequently, information quality;

EXAMPLE 6 ISO/TS 8000-81 specifies an approach to data profiling, which identifies opportunities to

improve data quality.

— issues that are specific to the type of content in a data set.

v

EXAMPLE 7 ISO/TS 8000-311 specifies how to address quality considerations for product shape data.

Data quality management covers all aspects of data processing, including creating, collecting, storing,

maintaining, transferring, exploiting and presenting data to deliver information.

Effective data quality management is systemic and systematic, requiring an understanding of the

root causes of data quality issues. This understanding is the basis for not just correcting existing

nonconformities but also implementing solutions that prevent future reoccurrence of those

nonconformities.

EXAMPLE 8 If a data set includes dates in multiple formats including “yyyy-mm-dd”, “mm-dd-yy” and “dd-mm-

yy”, then data cleansing can correct the consistency of the values. Such cleansing requires additional information,

however, to resolve ambiguous entries (such as, “04-05-20”) and cannot address any process issues and people

issues, including training, that have caused the inconsistency.

As a contribution to this overall capability of the ISO 8000 series, this document s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.