ISO 16112:2017

(Main)Compacted (vermicular) graphite cast irons — Classification

Compacted (vermicular) graphite cast irons — Classification

ISO 16112:2016 specifies five grades of compacted (vermicular) graphite cast irons. ISO 16112:2016 specifies five grades based on the minimum mechanical properties measured on machined test pieces prepared from - separately cast samples, - side-by-side cast samples, - cast-on samples, or - samples cut from a casting.

Fontes à graphite vermiculaire (compacté) — Classification

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 16112

Second edition

2017-02

Compacted (vermicular) graphite cast

irons — Classification

Fontes à graphite vermiculaire (compacté) — Classification

Reference number

©

ISO 2017

© ISO 2017, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2017 – All rights reserved

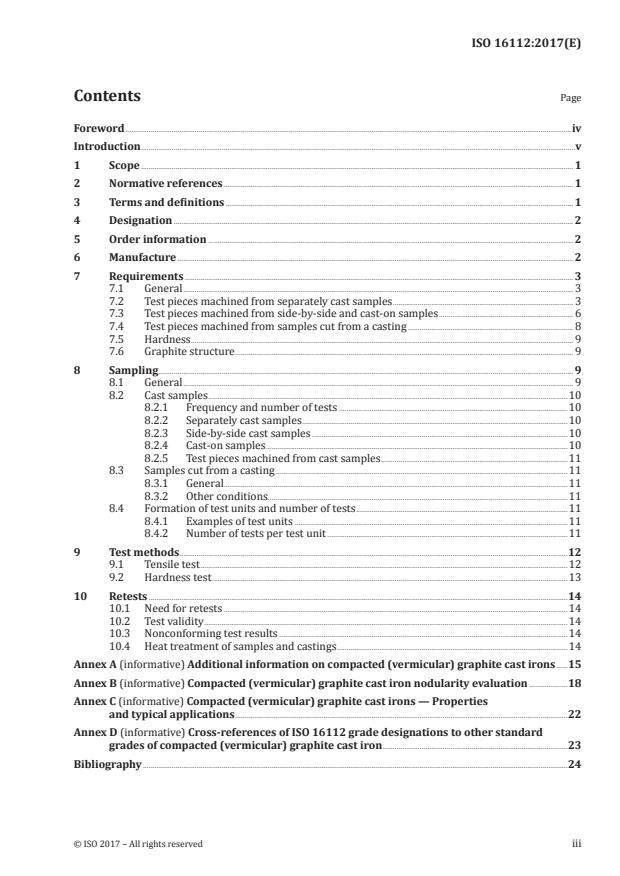

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Designation . 2

5 Order information . 2

6 Manufacture . 2

7 Requirements . 3

7.1 General . 3

7.2 Test pieces machined from separately cast samples . 3

7.3 Test pieces machined from side-by-side and cast-on samples . 6

7.4 Test pieces machined from samples cut from a casting . 8

7.5 Hardness . 9

7.6 Graphite structure . 9

8 Sampling . 9

8.1 General . 9

8.2 Cast samples .10

8.2.1 Frequency and number of tests .10

8.2.2 Separately cast samples .10

8.2.3 Side-by-side cast samples .10

8.2.4 Cast-on samples .10

8.2.5 Test pieces machined from cast samples .11

8.3 Samples cut from a casting .11

8.3.1 General.11

8.3.2 Other conditions.11

8.4 Formation of test units and number of tests .11

8.4.1 Examples of test units .11

8.4.2 Number of tests per test unit .11

9 Test methods .12

9.1 Tensile test .12

9.2 Hardness test .13

10 Retests .14

10.1 Need for retests .14

10.2 Test validity .14

10.3 Nonconforming test results .14

10.4 Heat treatment of samples and castings .14

Annex A (informative) Additional information on compacted (vermicular) graphite cast irons .15

Annex B (informative) Compacted (vermicular) graphite cast iron nodularity evaluation .18

Annex C (informative) Compacted (vermicular) graphite cast irons — Properties

and typical applications .22

Annex D (informative) Cross-references of ISO 16112 grade designations to other standard

grades of compacted (vermicular) graphite cast iron .23

Bibliography .24

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity assessment,

as well as information about ISO’s adherence to the World Trade Organization (WTO) principles in the

Technical Barriers to Trade (TBT) see the following URL: www . i so .org/ iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 25, Cast irons and pig irons.

This second edition cancels and replaces the first edition (ISO 16112:2006), which has been technically

revised with the following changes:

— Brinell hardness values have been moved from Table 1 and Table 2 to Table A.1;

— property values for cast-on samples with relevant wall thickness t ≤ 12,5 mm have been removed

from Table 2 because all data entries for t ≤ 12,5 mm were the same as the values for relevant wall

thickness 12,5 mm < t ≤ 30 mm;

— Annex B has been expanded to provide a more comprehensive explanation of the nodularity

evaluation technique;

— Annex C has been deleted and replaced because the series production experience gained since the

first publication of ISO 16112 in 2006 has surpassed the scope of the annex.

iv © ISO 2017 – All rights reserved

Introduction

This document deals with the classification of compacted (vermicular) graphite cast irons (CGI) in

accordance with the mechanical properties of the material.

The properties of compacted (vermicular) graphite cast irons depend on their graphite and matrix

microstructure.

The mechanical properties of the material can be evaluated on machined test pieces prepared from

— separately cast samples,

— samples cast in the mould alongside the casting, with a joint running system, hereafter called side-

by-side samples, or

— samples cast onto either the casting or the running system, hereafter referred to as cast-on

samples, or

— samples cut from a casting (only when an agreement is made between the manufacturer and the

purchaser).

The material grade is defined by mechanical properties measured on machined test pieces prepared

from separately cast samples, cast-on samples, or samples cut from the casting by agreement between

the manufacturer and the purchaser.

Annex A provides typical properties for compacted (vermicular) graphite cast irons obtained in

separately cast test bars.

Annex B provides information on a procedure to determine the graphite nodularity of the

microstructure.

Annex C provides information on properties and examples for typical applications of compacted

(vermicular) graphite cast irons.

Annex D provides cross-references of ISO 16112 grade designations to other national and international

standard grades of compacted (vermicular) graphite cast iron.

References used in the preparation of this document are listed in the Bibliography.

INTERNATIONAL STANDARD ISO 16112:2017(E)

Compacted (vermicular) graphite cast irons —

Classification

1 Scope

This document specifies five grades of compacted (vermicular) graphite cast irons.

This document specifies five grades based on the minimum mechanical properties measured on

machined test pieces prepared from

— separately cast samples,

— side-by-side cast samples,

— cast-on samples, or

— samples cut from a casting.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 945-1, Microstructure of cast irons — Part 1: Graphite classification by visual analysis

ISO 6506-1, Metallic materials — Brinell hardness test — Part 1: Test method

ISO 6892-1, Metallic materials — Tensile testing — Part 1: Method of test at room temperature

ISO/TR 15931, Designation system for cast irons and pig irons

3 Terms and definitions

For the pur

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.