ISO 23475-1:2021

(Main)Testing method for steel tyre cord — Part 1: General requirements

Testing method for steel tyre cord — Part 1: General requirements

This document specifies test methods of steel cords which are used for tyre reinforcement. Dimension, process properties, mechanical properties and coating test method are all included.

Méthode d'essai pour les câbles de pneumatiques en acier — Partie 1: Exigences générales

General Information

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 23475-1

First edition

2021-02

Testing method for steel tyre cord —

Part 1:

General requirements

Méthode d'essai pour les câbles de pneumatiques en acier —

Partie 1: Exigences générales

Reference number

©

ISO 2021

© ISO 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2021 – All rights reserved

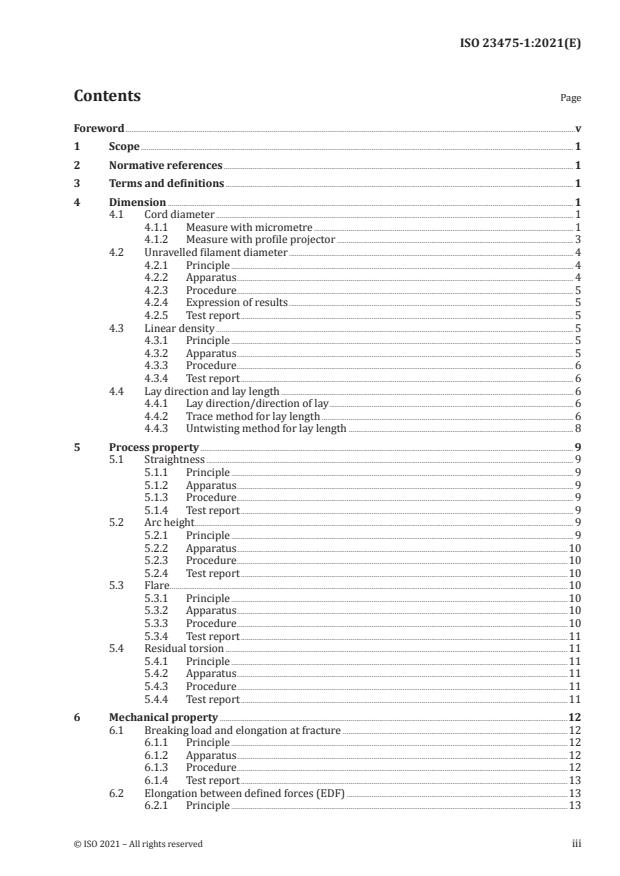

Contents Page

Foreword .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Dimension . 1

4.1 Cord diameter . 1

4.1.1 Measure with micrometre . 1

4.1.2 Measure with profile projector . 3

4.2 Unravelled filament diameter . 4

4.2.1 Principle . 4

4.2.2 Apparatus . 4

4.2.3 Procedure . 5

4.2.4 Expression of results . 5

4.2.5 Test report . 5

4.3 Linear density . 5

4.3.1 Principle . 5

4.3.2 Apparatus . 5

4.3.3 Procedure . 6

4.3.4 Test report . 6

4.4 Lay direction and lay length . 6

4.4.1 Lay direction/direction of lay . 6

4.4.2 Trace method for lay length . 6

4.4.3 Untwisting method for lay length . 8

5 Process property . 9

5.1 Straightness . 9

5.1.1 Principle . 9

5.1.2 Apparatus . 9

5.1.3 Procedure . 9

5.1.4 Test report . 9

5.2 Arc height . 9

5.2.1 Principle . 9

5.2.2 Apparatus .10

5.2.3 Procedure .10

5.2.4 Test report .10

5.3 Flare .10

5.3.1 Principle .10

5.3.2 Apparatus .10

5.3.3 Procedure .10

5.3.4 Test report .11

5.4 Residual torsion .11

5.4.1 Principle .11

5.4.2 Apparatus .11

5.4.3 Procedure .11

5.4.4 Test report .11

6 Mechanical property .12

6.1 Breaking load and elongation at fracture .12

6.1.1 Principle .12

6.1.2 Apparatus .12

6.1.3 Procedure .12

6.1.4 Test report .13

6.2 Elongation between defined forces (EDF) .13

6.2.1 Principle .13

6.2.2 Apparatus .14

6.2.3 Procedure .15

6.2.4 Test report .15

6.3 Loop test (Elasticity) .15

6.3.1 Principle .15

6.3.2 Apparatus .15

6.3.3 Procedure .16

6.3.4 Test report .17

7 Determination of mass and composition of coating by X-Ray fluorescence spectroscopy .17

7.1 Principle .17

7.2 Apparatus .17

7.2.1 WDXRFS or EDXRFS .17

7.2.2 Analytical balance, which can be read to the nearest 0,001 g. .17

7.2.3 Dispenser, with the accuracy of 25,00 ml ± 0,05 ml. .17

7.2.4 X/Y shaker, with variable frequency. .17

7.3 Reagents.17

7.3.1 Acetone or diethyl ether .17

7.3.2 Ammonium persulphate (mass fraction >98 %) .17

7.3.3 Ammonia (mass fraction >25 %, not more than “d=0,91” at temperature 20 °C) 17

7.3.4 Stripping solution, for 1 l: weigh 16 g ammonia persulphate into a

beaker of 600 ml and dissolve in 400 ml demineralized water. Transfer

quantitatively into a 1 l volumetric flask. Add 120 ml ammonia. Fill up to

the mark with demineralized water. Shake well. .17

7.3.5 Standard, the matrix and range should cover the sample rang

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.