ISO 12466-1:2007

(Main)Plywood — Bonding quality — Part 1: Test methods

Plywood — Bonding quality — Part 1: Test methods

ISO 12466-1:2007 specifies methods for determining the bonding quality of plywood, blockboard, battenboard, and laminboard, bonded with thermosetting resin, by shear testing.

Contreplaqué — Qualité du collage — Partie 1: Méthodes d'essai

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 12466-1

Second edition

2007-11-15

Plywood — Bonding quality —

Part 1:

Test methods

Contreplaqué — Qualité du collage —

Partie 1: Méthodes d'essai

Reference number

©

ISO 2007

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2007

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2007 – All rights reserved

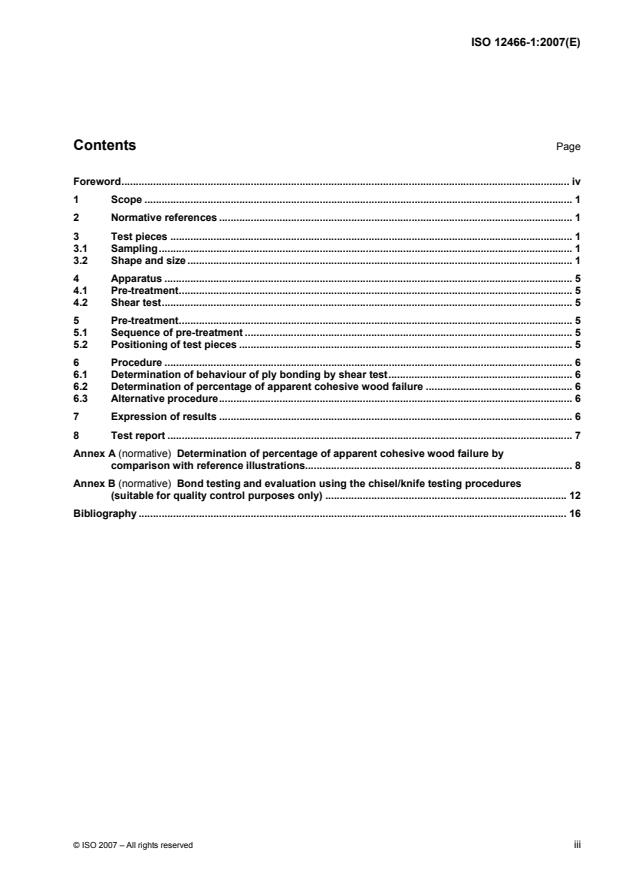

Contents Page

Foreword. iv

1 Scope . 1

2 Normative references . 1

3 Test pieces . 1

3.1 Sampling. 1

3.2 Shape and size. 1

4 Apparatus . 5

4.1 Pre-treatment. 5

4.2 Shear test. 5

5 Pre-treatment. 5

5.1 Sequence of pre-treatment . 5

5.2 Positioning of test pieces . 5

6 Procedure . 6

6.1 Determination of behaviour of ply bonding by shear test. 6

6.2 Determination of percentage of apparent cohesive wood failure . 6

6.3 Alternative procedure. 6

7 Expression of results . 6

8 Test report . 7

Annex A (normative) Determination of percentage of apparent cohesive wood failure by

comparison with reference illustrations. 8

Annex B (normative) Bond testing and evaluation using the chisel/knife testing procedures

(suitable for quality control purposes only) .12

Bibliography . 16

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 12466-1 was prepared by Technical Committee ISO/TC 89, Wood-based panels, Subcommittee SC 3,

Plywood.

This second edition cancels and replaces the first edition (ISO 12466-1:1999), which has been technically

revised.

ISO 12466 consists of the following parts, under the general title Plywood — Bonding quality:

⎯ Part 1: Test methods

⎯ Part 2: Requirements

iv © ISO 2007 – All rights reserved

INTERNATIONAL STANDARD ISO 12466-1:2007(E)

Plywood — Bonding quality —

Part 1:

Test methods

1 Scope

This part of ISO 12466 specifies methods for determining the bonding quality of plywood, blockboard,

battenboard, and laminboard, bonded with thermosetting resin, by shear testing.

NOTE If it is possible to demonstrate a correlation between the methods defined in this part of ISO 12466 and other

methods, these may be used.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 12466-2, Plywood — Bonding quality — Part 2: Requirements

ISO 16999, Wood-based panels — Sampling and cutting of test pieces

3 Test pieces

3.1 Sampling

Sampling shall be in accordance with ISO 16999.

Test pieces shall be without any visible defect in the testing area.

3.2 Shape and size

The test pieces shall be prepared as shown in Figures 1, 2 and 3.

Each test piece shall be cut so that the grain direction of the layer (ply) between the glue lines under test is

perpendicular to the length of the test piece.

The test pieces shall be prepared and nicking (saw cuts) made to allow the examination of each glue line of

the panel. The saw cuts shall extend inside the layer.

Test pieces of full-panel thickness may be used for panels with three to nine layers (plies). For panels of more

than nine layers, excess layers shall be removed by planing, cutting or sanding.

Key

b = (25 ± 0,5) mm shear width (width of test piece)

b = 2,5 mm to 4 mm saw cut width

l = (25 ± 0,5) mm shear length

l = 50 mm minimum distance between clamps

thickness = panel thickness

a

Along the grain direction.

Figure 1 — Test piece example for a 7-ply veneer plywood

2 © ISO 2007 – All rights reserved

a) part 1 b) part 2

c) bonding of the faces of the two parts and grooving

Key

1 face

2 back face

3 saw cuts throughout the face layers

b

4 faces of part 1 and part 2

5 glue-line not subject to the shear test

b = (25 ± 0,5) mm shear width

b = 2,5 mm to 4 mm saw cut width

l = (25 ± 0,5) mm shear length

l = 50 mm minimum distance between clamps

a

Along the grain direction.

b

The same set-up shall be made for the back face of part 1 and part 2.

Figure 2 — Composite test piece for blockboard and laminboard

a) part 1 b) part 2

c) bonding of the faces of the two parts and grooving

Key

1 face

2 back face

3 saw cuts throughout the face layers

b

4 faces of part 1 and part 2

5 glue-line not subject to the shear test

b = (25 ± 0,5) mm shear width

b = 2,5 mm to 4 mm saw cut width

l = (25 ± 0,5) mm shear length

l = 50 mm minimum distance between clamps

a

Along the grain direction.

b

The same set-up shall be made for the back face of part 1 and part 2.

Figure 3 — Composite test piece for thin-face plywood panel

4 © ISO 2007 – All rights reserved

4 Apparatus

4.1 Pre-treatment

4.1.1 Temperature-controlled water bath suitable for immersing test pieces and capable of maintaining a

minimum temperature of 17 °C.

4.1.2 Boiling tank enabling test pieces to be immersed in boiling water.

4.1.3 Ventilated drying oven capable of maintaining a temperature of (60 ± 3) °C at all points.

4.1.4 Vacuum pressure chamber capable of maintaining in water at room temperature a vacuum of

85 kPa for 30 min followed immediately by application of pressure of 450 kPa to 480 kPa for 30 min.

4.1.5 Autoclave capable of maintaining steam pressure at (200 ± 7) kPa for 6 h ± 15 min.

4.2 Shear test

Tensile testing machine fitted with serrated wedge action grips, capable of operating continuously and

measuring the load to an accuracy: ± 1 %.

5 Pre-treatment

5.1 Sequence of pre-treatment

The choice of pre-treatment, described in 5.1.1 to 5.1.6, for particular plywood classes, shall be made in

accordance with ISO 12466-2.

5.1.1 24 h Cold soak: immersion for 24 h in water at a temperature not lower than 17 °C.

NOTE (20 ± 3) °C can be considered as a test reference temperature.

5.1.2 6 h Boil: immersion for 6 h in boiling water, followed by cooling in water at less than 30 °C for at least

1 h.

5.1.3 BDB: immersion for 4 h in boiling water, then drying in the ventilated drying oven for 16 h to 20 h at

(60 ± 3) °C, then immersion in boiling water for 4 h, followed by cooling in water at less than 30 °C for at least

1 h.

5.1.4 VP: test specimens are immersed in water at room temperature and a vacuum of 85 kPa is applied for

30 min followed by the immediate application of a pressure of 450 kPa to 480 kPa for 30min.

5.1.5 72 h Boil: immersion for (72 ± 1) h in boiling water, followed by cooling in water at less than 30 °C for

at least 1 h.

5.1.6 Steam: specimens are placed in steam at (200 ± 7) kPa pressure for 6 h ± 15 min followed by cooling

for at least 1 h in water at less than 30 °C.

5.2 Positioning of test pieces

The test pieces shall be placed, well separated and free to move, in a wire basket. During soaking, each test

piece shall remain completely immersed in water.

6 Procedure

6.1 Determination of behaviour of ply bonding by shear test

Before the water treatment, measure the length and width of the shear area to an accuracy of 0,1 mm and

record.

Arrange the shear test pieces in the centre of the clamping device in such a way that the load can be

transmitted from the testing machine, via the ends of the test pieces, to the shear area without any transverse

load. If slipping occurs, it shall only be allowed in the initial stage of the loading.

Apply the load at a constant speed so that failure occurs within (30 ± 10) s.

Determine and record the load at failure, to an accuracy of 1 %. Calculate the shear strength, in megapascals,

in accordance with Clause 7.

After the shear test, determine the apparent cohesive wood failure in accordance with 6.2.

6.2 Determination of percentage of apparent cohesive wood failure

Allow the test pieces to dry before determination of apparent cohesive wood failure.

The percentage of apparent cohesive wood failure shall be determined by comparison with the standard

illustrations in Annex A, by 10 % increments from 0 % to 100 %, and recorded.

Failure should normally occur in the wood or in the glue lines between the saw cuts, i.e. within the shear test

area. If failure occurs outside the test area, or by cross-grain breaking within 50 % or more of the surface of a

face veneer, reject the result and repeat the test with a shear length of 10 mm.

Failures resulting from the presence of strength-reducing defects shall also be excluded, with the exception of

test pieces containing tape. Test pieces with such defects should normally be identified and replaced during

the cutting operation. If the number of test pieces rejected exceeds 20 %, it is necessary to resample. If the

re-sampling is also rejected on this basis, then the batch shall be rejected.

6.3 Alternative procedure

An alternative procedure for bond testing and evaluation, the knife or chisel test, is provided in Annex B.

This procedure is deemed suitable for quality control purposes only.

7 Expression of results

Calculate the shear strength, τ, in megapascals, of each test piece, fr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.