ISO 16413:2020

(Main)Evaluation of thickness, density and interface width of thin films by X-ray reflectometry — Instrumental requirements, alignment and positioning, data collection, data analysis and reporting

Evaluation of thickness, density and interface width of thin films by X-ray reflectometry — Instrumental requirements, alignment and positioning, data collection, data analysis and reporting

This document specifies a method for the evaluation of thickness, density and interface width of single layer and multi-layered thin films which have thicknesses between approximately 1 nm and 1 μm, on flat substrates, by means of X-Ray Reflectometry (XRR). This method uses a monochromatic, collimated beam, scanning either an angle or a scattering vector. Similar considerations apply to the case of a convergent beam with parallel data collection using a distributed detector or to scanning wavelength, but these methods are not described here. While mention is made of diffuse XRR, and the requirements for experiments are similar, this is not covered in the present document. Measurements may be made on equipment of various configurations, from laboratory instruments to reflectometers at synchrotron radiation beamlines or automated systems used in industry. Attention should be paid to an eventual instability of the layers over the duration of the data collection, which would cause a reduction in the accuracy of the measurement results. Since XRR, performed at a single wavelength, does not provide chemical information about the layers, attention should be paid to possible contamination or reactions at the specimen surface. The accuracy of results for the outmost layer is strongly influenced by any changes at the surface. NOTE 1 Proprietary techniques are not described in this document.

Évaluation de l'épaisseur, de la densité et de la largeur de l'interface des films fins par réflectrométrie de rayons X — Exigences instrumentales, alignement et positionnement, rassemblement des données, analyse des données et rapport

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 16413

Second edition

2020-08

Evaluation of thickness, density

and interface width of thin films by

X-ray reflectometry — Instrumental

requirements, alignment and

positioning, data collection, data

analysis and reporting

Évaluation de l'épaisseur, de la densité et de la largeur de l'interface

des films fins par réflectrométrie de rayons X — Exigences

instrumentales, alignement et positionnement, rassemblement des

données, analyse des données et rapport

Reference number

©

ISO 2020

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

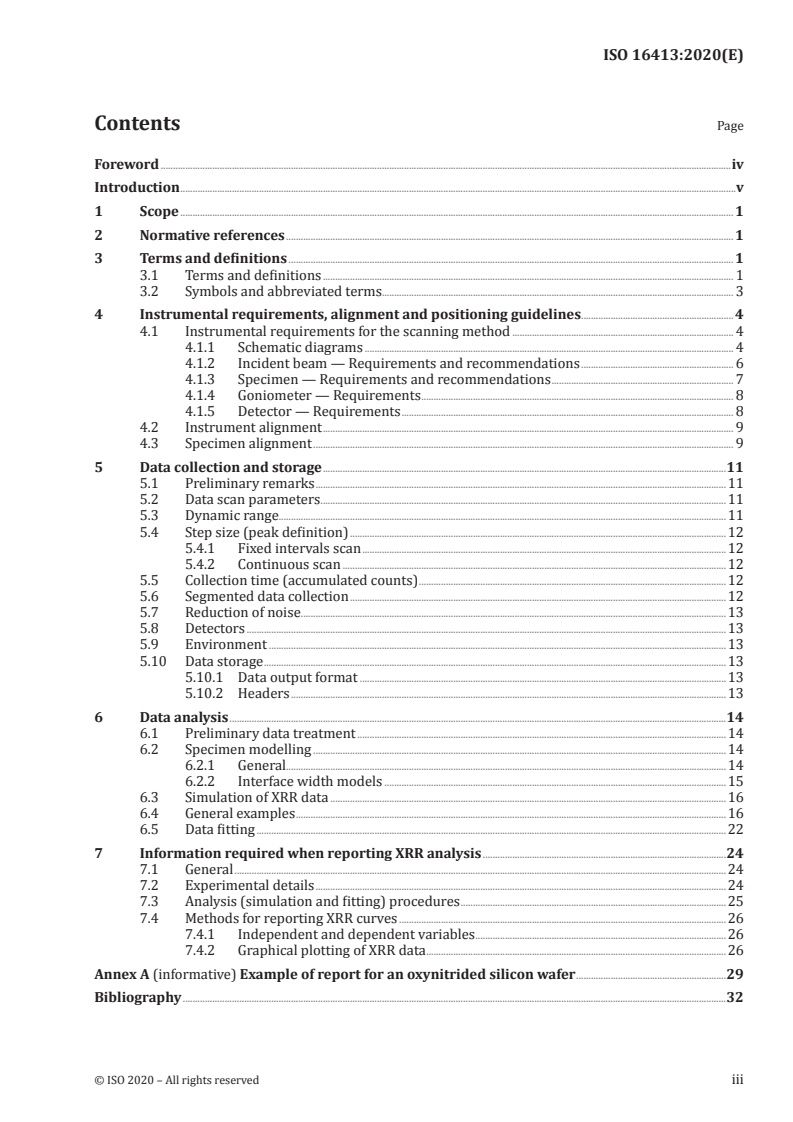

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

3.1 Terms and definitions . 1

3.2 Symbols and abbreviated terms. 3

4 Instrumental requirements, alignment and positioning guidelines .4

4.1 Instrumental requirements for the scanning method . 4

4.1.1 Schematic diagrams . 4

4.1.2 Incident beam — Requirements and recommendations . 6

4.1.3 Specimen — Requirements and recommendations . 7

4.1.4 Goniometer — Requirements . 8

4.1.5 Detector — Requirements . 8

4.2 Instrument alignment . 9

4.3 Specimen alignment . 9

5 Data collection and storage .11

5.1 Preliminary remarks .11

5.2 Data scan parameters .11

5.3 Dynamic range.11

5.4 Step size (peak definition) .12

5.4.1 Fixed intervals scan .12

5.4.2 Continuous scan .12

5.5 Collection time (accumulated counts) .12

5.6 Segmented data collection .12

5.7 Reduction of noise .13

5.8 Detectors .13

5.9 Environment .13

5.10 Data storage .13

5.10.1 Data output format .13

5.10.2 Headers .13

6 Data analysis .14

6.1 Preliminary data treatment .14

6.2 Specimen modelling .14

6.2.1 General.14

6.2.2 Interface width models .15

6.3 Simulation of XRR data .16

6.4 General examples .16

6.5 Data fitting .22

7 Information required when reporting XRR analysis .24

7.1 General .24

7.2 Experimental details .24

7.3 Analysis (simulation and fitting) procedures .25

7.4 Methods for reporting XRR curves .26

7.4.1 Independent and dependent variables .26

7.4.2 Graphical plotting of XRR data .26

Annex A (informative) Example of report for an oxynitrided silicon wafer .29

Bibliography .32

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see www .iso .org/

iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 201, Surface chemical analysis.

This second edition cancels and replaces the first edition (ISO 16413:2013), of which it constitutes a

minor revision. The changes compared to the previous edition are as follows:

— editorial changes, mainly for a more precise description, e.g. ‘incidence angle’ has been replaced by

‘grazing incidence angle’, ‘intensity’ has been replaced in the appropriate diagrams by ‘reflectivity’ etc.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

iv © ISO 2020 – All rights reserved

Introduction

X-Ray Reflectometry (XRR) is widely applicable to the measurement of thickness, density and interface

width of single layer and multi-layered thin films which have thicknesses between approximately 1 nm

and 1 μm, on flat substrates, provided that the layer, equipment and X-ray wavelength are appropriate.

Interface width is a general term; it is typically composed of interface or surface roughness and/or

density grading across an interface. The specimen needs to be laterally uniform under the footprint of

the X-ray beam. In contrast with typical surface chemical analysis methods which provide information

of the amount of substance and need conversion to estimate thicknesses, XRR provides thicknesses

directly traceable to the unit of length. XRR is very powerful method to measure the thickness of thin

film with SI traceability.

The key requirements for equipment suitable for collecting specular X-ray reflectivity data of high

quality, and the requirements for specimen alignment and positioning so that useful, accurate

measurements may be obtained are described in Clause 4.

The key issues for data collection to obtain specular X-ray reflectivity data of high quality, suitable

for data treatment and modelling are described in Clause 5. The collection of the data is traditionally

conducted by running single measurements under direct operator data input. However, recently data

are often collected by instructing the instrument to operate in multiple runs. In addition to the operator

mode, data can be collected making use of automated scripts, when available in the software program

controlling the instrument.

The principles for analysing specular XRR data in order to obtain physically meaningful material

information about the specimen are described in Clause 6. While specular XRR fitting can be a

complex process, it is possible to simplify the implementation for quality assurance applications to the

extent where it can be transparent to the user. There are many software packages, both proprietary

and non-proprietary available for simulation and fitting of XRR data. It is beyond the scope of this

document to describe details of theories and algorithms. Where appropriate, references are given for

the interested reader.

The information required when reporting on XRR experiments is listed in Clause 7. A brief review of the

possible ways to present XRR data and results is given and, when more than one option is available, the

preferred one is indicated.

This document is not a textbook, it is a standard for performing XRR measurements and analysis.

For a full explanation of the technique, please consult appropriate references [e.g. D. Keith Bowen

and Brian K. Tanner, “X-Ray Metrology in Semiconductor Manufacturing”, Taylor and Francis, London

(2006); M. Tolan, “X-ray Reflectivity from Soft Matter Thin Films“, Springer Tracts in Modern Physics

vol. 148 (1999); U. Pietsch, V. Holy and T. Baumbach, “High Resolution X-Ray Scattering from Thin Films

to Lateral Nanostructures”, Springer (2004); J. Daillant and A. Gibaud, “X-ray and Neutron Reflectivity:

Principles and Applications”, Springer (2009)].

Safety aspects related to the use of X-ray equipment are not considered in this document. During the

measurements, the adherence to relevant safety procedures as imposed by law are the responsibilities

of the user.

INTERNATIONAL STANDARD ISO 16413:2020(E)

Evaluation of thickness, density and interface width of thin

films by X-ray reflectometry — Instrumental requirements,

alignment and positioning, data collection, data analysis

and reporting

1 Scope

This document specifies a method for the evaluation of thickness, density and interface width of single

layer and multi-layered thin films which have thicknesses between approximately 1 nm and 1 μm, on

flat substrates, by means of X-Ray Reflectometry (XRR).

This method uses a monochromatic, collimated beam, scanning either an angle or a scattering vector.

Similar considerations apply to the case of a convergent beam with parallel data collection using a

distributed detector or to scanning wavelength, but these methods are not described here. While

mention is made of diffuse XRR, and the requirements for experiments are similar, this is not covered in

the present document.

Measurements may be made on equipment of various configurations, from laboratory instruments to

reflectometers at synchrotron radiation beamlines or automated systems used in industry.

Attention should be paid to an eventual instability of the layers over the duration of the data collection,

which would cause a reduction in the accuracy of the measurement results. Since XRR, performed at a

single wavelength, does not provide chemical information about the layers, attention should be paid to

possible contamination or reactions at the specimen surface. The accuracy of results for the outmost

layer is strongly influenced by any changes at the surface.

NOTE 1 Proprietary techniques are not described in this document.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

3.1 Terms and definitions

3.1.1

grazing incidence angle

ω (omega)

angle between the incident beam and the specimen surface

Note 1 to entry: This angle is sometimes called ‘glancing angle’.

3.1.2

critical angle

θ

c

angle between the incident beam and the specimen surface, below which there is total external

reflection of X-rays, and above which the X-ray beam penetrates below the surface of the specimen

Note 1 to entry: The critical angle for a given specimen material or structure can be found by using simulation

software, or approximated from the formula θδ≈ 2 where 1 − δ is the real part of the complex X-ray refractive

c

index n = 1 − δ − iβ.

3.1.3

specimen length

dimension of the specimen in the plane of the incident and reflected X-ray beams and in the plane of the

specimen

3.1.4

specimen width

dimension of the specimen perpendicular to the plane of the incident and reflected X-ray beams and in

the plane of the specimen

3.1.5

specimen height

dimension (thickness) of the specimen perpendicular to the plane of the specimen

3.1.6

layer thickness

thickness of an individual layer on the substrate

3.1.7

beam footprint

area on the specimen irradiated by the X-ray

3.1.8

beam spill-off

effect of grazing incidence that involves the reduction of the measured reflected intensity when part of

the incident beam is not intercepted by the specimen, so that the part spills off the specimen

3.1.9

instrument function

analytical function describing the effects of instrument and resolution on the observed scattered X-ray

intensity

3.1.10

reciprocal space

representation of the physical specimen and X-rays where the distance plotted is proportional to the

inverse of real-space distances, and angles correspond to real-space angles

3.1.11

wave vector

k

vector in reciprocal space describing the incident or scattered X-ray beams

3.1.12

scattering vector

q

vector in reciprocal space giving the difference between the scattered and incident wave vectors

3.1.13

dispersion plane

plane containing the source, detector, incident and specularly reflected X-ray beams

2 © ISO 2020 – All rights reserved

3.1.14

specular X-ray reflectivity

reflected X-ray signal detected at an angle with the specimen surface as the incident X-ray beam with

the specimen surface: 2θ/2 = ω

Note 1 to entry: The detected, scattered X-ray intensity is measured as a function of either ω or 2θ or q (usually

z

presented against q or i).

z

3.1.15

diffuse X-ray reflectivity

X-ray scatter arising from the imperfection of the specimen

3.1.16

fringe

one of the repeating maxima in reflectometry data which arise from interference of the X-ray waves

Note 1 to entry: Fringe periods are related to the thickness of a layer (or layers) of contrasting electron density.

Multiple layers give rise to series of superposed interfering fringes.

3.1.17

fringe contrast

qualitative description of the height of a fringe (3.1.16) between its minimum and its maximum

Note 1 to entry: The greater the difference between minimum and maximum, the greater the contrast is said to be.

3.1.18

electron density

ρ

e

electrons per unit volume

3 3

Note 1 to entry: XRR typically measures electron density in electrons per nm or per Å .

Note 2 to entry: This can be calculated from mass density.

3.1.19

mass density

ρ

common density (mass per unit volume)

−3 −3

Note 1 to entry: The unit of the mass density is kg m (or g cm ).

3.1.20

absorption length

L

abs

distance over which the transmitted intensity falls to 1/e of the incident intensity

3.1.21

X,Y,Z coordinate system

orthogonal coordinate system in which X is the direction in the plane of the specimen, parallel to the

incident beam when ϕ = 0; Y is the direction in the plane of the specimen, perpendicular to the incident

beam when ϕ = 0; and Z is the direction normal to the plane of the specimen

3.2 Symbols and abbreviated terms

2θ angle of the detected X-ray beam with respect to the incident X-ray beam

ω angle between the incident X-ray beam and the specimen surface

ϕ angle of rotation about the normal to the nominal surface of the specimen

χ angle of tilt of specimen about an axis in the plane of the specimen and in the plane of the

incident X-ray beam, X-ray source and detector

θ critical angle

c

λ wavelength of the incident X-ray beam

ρ mass density

ρ electron density

e

k wave vector

q scattering vector

q scalar magnitude of the component of the scattering vector in reciprocal space normal to

Z

the specimen surface (corrected or uncorrected for refraction). q = sin(θ) × 4π/λ

Z

σ root mean square height of the scale-limited surface (according to ISO 25178-2) or

interface width

L absorption length in the specimen

abs

XRR X-Ray Reflectometry or X-Ray Reflectivity

4 Instrumental requirements, alignment and positioning guidelines

4.1 Instrumental requirements for the scanning method

4.1.1 Schematic diagrams

The principal requirements are on the beam size and beam positioning over the coaxial centres of

rotation of specimen (ω) and detector (2θ) axes.

Figure 1 shows a diagram of a basic collimated beam, scanning configuration for an XRR experiment.

The case of a convergent beam and distributed detector is not shown.

4 © ISO 2020 – All rights reserved

Key

ω angle between the specimen surface and the incident X-ray beam

2θ angle between the detected beam and 2θ = 0 (the extension of the incident X-ray beam)

(i) X-ray source

(ii) collimated incident x-ray beam

(iii) specimen

(iv) centre of rotation

(v) reflected x-ray beam

(vi) detection system

NOTE The centre of rotation, where incident and reflected beams, the specimen surface and the rotation

axes of ω and 2θ coincide, is highlighted as grey disc.

Figure 1 — Schematic layout of a typical scanning XRR experimental configuration, projected

into the plane of the source, detector, incident and specularly-reflected X-ray beams (the

dispersion plane)

Figure 2 shows a schematic diagram of scanning configuration XRR in a three-dimensional view,

indicating the diffuse scatter as well as the specularly reflected X-ray beam.

Key

ω angle between the specimen surface and the incident X-ray beam

2θ angle between the detected beam (at 2θ = 0) and whichever part of the reflected beam is of interest (the

detected beam)

(i) X-ray source

(ii) collimated incident x-ray beam

(iii) specimen

(iv) diffusely scattered x-rays

(v) specularly reflected x-ray beam

Figure 2 — Schematic diagram showing specular and diffusely reflected X-ray beams

4.1.2 Incident beam — Requirements and recommendations

4.1.2.1 Incident beam — Requirements

The following requirements shall apply to the collimated beam, scanning method. Similar considerations

apply to the convergent beam, parallel data collection method.

a) The incident beam shall be stable (or can be compensated) within the time-frame of the experiment.

b) The incident beam shall be nominally monochromatic. The wavelength dispersion dλ shall fulfil

the following condition: dλ < λdθ/tan(θ ) where dθ is the beam divergence and θ is typically the

m m

maximum incidence angle where fringes are still observed.

EXAMPLE If using an incident beam of Cu Kα radiation (λ = 0,154 1 nm) with an angular divergence of

50 arc seconds, and if fringes are to be observed out to an incident angle of 3,5°, then dλ needs to be less than

0,035 nm.

c) If the beam is not sufficiently collimated, the divergence of the beam limits the maximum detectable

thickness. Practically, the maximum measurable thickness is less than λ/6sin(dθ) where dθ is

the beam divergence for a suitable specimen. For typical laboratory equipment, the limit is a few

hundred nm.

d) The incident intensity shall be such as to allow several orders of magnitude intensity range above

background, since reflected intensity falls rapidly above the critical angle. Below the critical

angle, there is total external reflection. Above the critical angle, reflected intensity falls at a rate

−4

proportional to q for a perfectly smooth surface, and more rapidly than this for rough or/and

z

graded surfaces.

4.1.2.2 Incident beam — Recommendations

The following recommendations concern the collimated beam, scanning method. Similar considerations

concern the convergent beam, parallel data collection method.

a) The specimen should be laterally uniform under the area irradiated (the beam footprint) and

observed by the detector. This may be achieved by control of incident and scattered beam slits and/

or, for example, inserting a knife-edge near the specimen.

b) Beam spill-off should be minimized. This is especially important when the specimen angle is near

and above the critical angle. The beam width compared to the specimen length should be such that

there is no beam spill-off for a specimen angle which is above about 75 % (preferably less) of the

critical angle. (See Figure 3.)

NOTE With the specimen parallel to the beam (ω = 0), the beam covers all of the specimen. The beam

footprint varies with incident angle unless slits or knife-edge position are varied through the scan).

1) The maximum acceptable beam width for a given specimen size can then be found by geometry.

2) If there are very small specimens, it may not be practical to meet the recommended

requirements. In this case, the accuracy and precision of densities and interface widths

deduced may be compromised.

3) This is necessary so that the position of the critical angle can be ascertained with reasonable

confidence, so that, if data analysis includes layer density and interface width parameters,

these can be deduced with reasonable accuracy.

4) Some modelling and data fitting software allow the specimen size and beam size to be input,

which allows data fitting where there is significant beam spill-off, but even so it is recommended

that the specimen fill the incident beam from below the critical angle in order to have high

confidence in fitting this region and obtaining good density information.

6 © ISO 2020 – All rights reserved

Key

−1

X q , in nm simulated specular reflectivity of 20,0 nm Si N (with

Z 3 4

Y reflectivity 0,6 nm surface roughness) on bulk Si (with 0,3 nm

interface width), without instrument function

simulated specular reflectivity of 20,0 nm Si N (with

3 4

0,6 nm surface roughness) on bulk Si (with 0,3 nm

interface width), with instrument function (0,5 mm

source and detector slits and a 10 mm specimen)

NOTE The position of the critical angle for the small specimen is unclear and possibly apparently shifted,

and the rate of decrease of reflected intensity with increasing specimen angle is affected. This affects the

roughness or interface width deduced if the instrument function is not accurately taken into account in analysis.

The positions of fringes are unaffected, so thickness analysis can proceed successfully.

Figure 3 — Simulated specular reflectivity of 20,0 nm Si N on bulk Si, with and without

3 4

instrument function

c) If the above recommended condition cannot be met, provided that spill-off does not continue much

beyond the critical angle, fringes in the reflectometry data will still give an accurate measure of

layer thicknesses.

d) That portion of the X-ray beam measured at the detector should not spill off the specimen

perpendicular to the dispersion plane (the dispersion plane is perpendicular to the plane of

Figure 1) in the case where measuring the direct beam intensity is used to align the specimen

accurately over the centre of rotation of ω and 2θ.

4.1.3 Specimen — Requirements and recommendations

4.1.3.1 Specimen — Requirements

The following basic requirements shall be verified.

— XRR is a near-surface-sensitive technique. The specimen shall therefore be handled or treated only

in such ways that the surface is not modified or that any modification is taken into account in the

interpretation of the data. Modifications could include touching, mechanical or chemical polishing.

4.1.3.2 Specimen — Recommendations

The following basic recommendations should be followed.

a) The specimen should be laterally uniform under the beam footprint observed by the detector.

b) The specimen should fill the incident beam from a specimen angle significantly below the critical

angle and for angles above this. It is recommended that the specimen should fill the beam from a

maximum of 75 % of the critical angle.

c) The specimen should not be significantly bowed, or alignment precision and data quality are

compromised. The effect of curvature can be minimized by minimizing the beam footprint on the

specimen. It is recommended that the specimen should fill the beam from a maximum of 75 % of

the critical angle. It may be possible to proceed with data analysis from curved specimens. Some

data fitting models can take specimen curvature into account. Thickness values may be obtained

with sufficient accuracy, but the accuracy of interface widths and density is poorer.

d) The specimen surface and interfaces (where applicable) should be smooth, with a root mean square

(rms) roughness or interface width less than or similar to L /θ . Refer to 5.2.1 for a more detailed

abs c

description of roughness and interface width. Typically, this means σ < 5 nm maximum (above

which, special models must be applied for the analysis) and preferably σ < 3,5 nm. Where the

surface or interfaces are too rough, reflected intensity falls too rapidly with increasing specimen

angle, and reflectometry data give no useful material information. Models used to fit data are also

less reliable at very high interface widths.

4.1.4 Goniometer — Requirements

The following basic requirements shall be verified.

a) A mechanically well-aligned and stable X-ray goniometer is required.

b) For a scanning configuration, the ω and 2θ axes shall be capable of being moved such that intervals

can be maintained in the ratio Δ(2θ) = 2(Δω). Maintaining the ratio to one part in 1 000 is typically

sufficient.

c) The intervals of ω and 2θ shall be capable of being small enough that at least five data points may be

collected over a single thickness fringe. More data points are required for more complex specimens.

d) The specimen height (Z) shall be capable of being set accurately on the centre of rotation of ω and

2θ axes.

e) The specimen stage angle of tilt (χ) shall enable setting the specimen parallel to the incident

beam slits.

4.1.5 Detector — Requirements

The following basic requirements shall be verified.

a) The detector response shall be stable within the time-frame of the experiment.

b) For the specular reflectivity data to be collected in a single scan, the angular resolution of the

detector shall be such as to allow discrimination between the specular and diffuse reflectivity. It is

usual and recommended that the acceptance slits at the detector (where applicable) be set to match

the incident beam width and divergence.

c) Either the detector shall be capable of linear (or linearized) response over the whole reflected

intensity range (several orders of magnitude) or a system of calibrated attenuators to limit the

detected intensity is required over appropriate parts of the data range in order that the detector

can be linear (or linearized) in that range. Data in the different sections are then normalized using

the attenuation factors.

8 © ISO 2020 – All rights reserved

NOTE For the requirements of specular reflectometry, as here, there is no discrimination in the plane

perpendicular to the dispersion plane (i.e. in the plane perpendicular to the diagram in Figure 1). Reflected

intensity is integrated in this direction.

4.2 Instrument alignment

Alignment checks may be part of automated routines available on particular equipment. Slit collimation

of the scattered radiation is assumed. The procedure below describes one approach to align the

instrument 2θ axis

a) Set the X-ray source slit width to minimize spill off (typically 0,1 mm to 0,2 mm in a laboratory

system).

b) Make sure that nothing unwanted obstructs the beam between the source and detector. The

specimen and specimen mounting shall be out of the beam.

c) Start with the detector slits significantly wider than the source slits (many times wider).

d) The incident X-ray beam shall be accurately centred on the centre of rotation of the specimen and

detector axes.

NOTE It is possible, with modern control software, that corrections to axes motions take into account a

non-ideal instrument alignment.

e) Set the detector slit width so that the acceptance angle is similar to the incident beam divergence.

This typically means that the detector slit width is set the same as the source slit width in a

laboratory system or about 20 % wider.

f) Scan the detector angle across the incident beam. The peak should be an approximately symmetric

single maximum. Locate the position of the centre of the peak maximum (approximately at the

centre of mass). Move the detector to this position to set the 2θ = 0 position accurately.

4.3 Specimen alignment

Equipment and its controls may include automatic specimen alignment, data collection and analysis

routines, and may make use of other methods of alignment, e.g. range finders or position monitors.

The procedure below describes one approach to specimen alignment relative to the X-ray beam in an

aligned instrument.

a) The instrument shall be aligned correctly, with appropriate slit widths, with the incident beam

accurately over the centre of rotation and the detector angle 2θ = 0 correctly set on the incident beam.

b) The angle, ω, between specimen surface and incident beam shall be calibrated so that zero sets the

specimen surface approximately parallel to the incident beam.

c) If using a knife-edge, its position in Z, X, and tilt perpendicular to the beam direction (where

available) shall be carefully set. This is done after adjusting the specimen position. The

manufacturer’s recommended operating instructions should be consulted.

d) Mount the specimen on the specimen stage, in a suitable and repeatable orientation as far as

possible, e.g. notch or flat down, or cleaved edge parallel or perpendicular to the beam direction.

e) Where applicable, set the X-ray generator power to the manufacturer’s recommended operating

level. Ensure stable operation.

f) Move χ such that the specimen surface is nominally perpendicular to the plane containing the

source, incident beam and detector.

g) Move the specimen to the X, Y, ϕ position required for the measurement. Make sure that nothing

unwanted (such as the means of specimen mounting) can interfere with the incident or reflected

beams.

h) Initially, make sure that Z is such that the incident beam initially passes unhindered past the

specimen.

i) If required, insert an attenuator in the beam so that the detected intensity is well within the linear

or linearized regime of the detector. Note the full beam intensity, I .

full

j) Move Z to move the specimen into the beam until about one quarter to one fifth of the full beam

intensity is observed, i.e. move Z until I ~I /4 to ~I /5.

observed full full

k) Adjust ω until a maximum intensity is observed. If the maximum intensity is more than half the full

beam intensity, go back to step (j).

l) Scan ω to find more precisely the position of maximum intensity. Set ω here.

m) Now set χ. Move Z until the incident beam is nearly eclipsed (to about 2 % of full beam intensity).

n) Scan χ both sides of the nominal position.

o) Set χ to the minimum of the scan profile.

p) Move Z until I = I /2.

observed full

q) Scan ω again, and set ω at the intensity maximum, which should be I /2.

full

r) Make small adjustments in Z and ω if required until the maximum intensity on an ω scan is I /2.

full

The specimen is now parallel to the incident beam and half way into it. Since the beam is over the

centre of rotation of ω and 2θ, the surface of the specimen is now also over the centre of rotation.

s) It is standard practice on some XRR equipment to fit a knife-edge close to the specimen to define

the beam and reduce scatter, although this is not essential on all equipment for obtaining high

quality data. If a knife-edge is in use, it is set and adjusted at this point. Procedures are specific to

the particular equipment configuration in use, and so are not discussed here.

t) Move 2θ to an angle significantly above the critical angle but such that there is sufficient intensity

in the specularly reflected beam, i.e. well above the background level of the detector. Move ω to

half 2θ.

NOTE In general, moving 2θ to ~0,5° to 1,0° (~1 800 to 3 600 arc sec) will be appropriate if using Cu Kα

radiation or similar.

u) Reflected intensity is generally much weaker than the direct incident beam. Adjust or remove the

attenuator (if applicable) in order that a clear intensity within the linear or linearized response of

the detector is measurable. If the intensity is too low, decrease 2θ until a significant signal appears,

but do not get too close to the critical angle.

v) Scan the ω axis over a sufficient range to see a clear peak as the specimen passes through the

specular reflection condition. Then set ω to the point of highest intensity (Figure 4). This refines

the specimen angle setting on a specular reflection and is more precise than relying on setting the

specimen surface parallel to the incident beam.

w) Go back to step p) and recheck the half beam position. If the half beam position changes, retract the

knife edge (if used) and re-check the procedure from step p) onward.

x) The instrument may have an axis called ω - 2θ or θ - 2θ, in which case it may be helpful to recalibrate

this axis to half the 2θ value. Or it may have an axis called 2θ - θ, in which case it may be helpful to

recalibrate this at the 2θ value. However, the instrument controls may not permit this.

The specimen is now aligned and ready to scan.

10 © ISO 2020 – All rights reserved

Key

X omega, in degrees

Y normalized intensity

Figure 4 — Scan of ω through the specular condition, with 2θ fixed at 1°

5 Data collection and storage

5.1 Preliminary remarks

The X-ray generator shall be operating stably to the manufacturer's specification in an appropriate

environment. Particular care shall be taken on switching on an X-ray generator, to allow a reasonable

time to establish stable working conditions of electronics and X-ray beam. Refer to the manufacturer’s

start-up procedures.

5.2 Data scan parameters

For data collection, ω and 2θ angles are required to be moved or scanned. The specular angular

condition ω = θ shall be fulfilled at each data collection point.

The scanning time is the time necessary to obtain the entire scan. Whenever possible, it is recommended

to calculate, or at least estimate, the scanning time. This is particularly important when multiple scans

or automated scripts are used for the data collection.

The collection time at each point may be kept fixed or variable (accumulated counts) (see 4.5).

5.3 Dynamic range

It is recommended that scans shall begin at ω = θ = 0° and end when reaching the background level.

Following this recommendation will allow the best data analysis. However, to reduce scanning time, for

particular requirements, limited range data scans can be collected.

A reliable alternative method to reduce the scanning time is the use of multiple scans for the data

collection. Multiple scans allow the average of the data collected over different scans, taken at the same

conditions, improving the statistics.

5.4 Step size (peak definition)

5.4.1 Fixed intervals scan

The intervals of ω and 2θ shall be capable of being small enough that at least five data points may be

collected over a single thickness fringe. More data points are required for more complex specimens.

a) Five points on a fringe are sufficient for rapid analysis of a well-defined single-layer specimen

where there is good fringe contrast.

b) Seven points is typically recommended over a single fringe. More data points may be collected if

desired.

c) If the specimen structure has multiple layers giving overlapping and interfering fringes in the

reflectometry data, more points per fringe may be required in order to define the shape accurately

and so enable analysis to distinguish between multiple layers.

Scanning in step size at fixed intervals is rather common.

5.4.2 Continuous scan

Alternatively, instead of a scan in intervals with data collection at each point, ω and 2θ can be

continuously moved at a constant speed, while the data are collected with a fixed sampling rate

(sampling time).

The same conditions on points over fringe as in 5.4.1 shall be fulfilled also in the continuous scan

approach.

This approach is recommended when a simple specimen structure is measured over a large dynamic

range (2θ > 10°) in the presence of a fast-dynamic detector, because it optimizes the collection and

scanning time.

5.5 Collection time (accumulated counts)

The collection time may be kept fixed or variable. The latter is also known as accumulated counts

approach.

In the fixed collection time approach, each data point is collected over the same time interval.

In the accumulated counts approach, the collecting time at each data

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.