ISO/TR 9705-2:2001

(Main)Reaction-to-fire tests — Full-scale room tests for surface products — Part 2: Technical background and guidance

Reaction-to-fire tests — Full-scale room tests for surface products — Part 2: Technical background and guidance

This part of ISO 9705 provides guidance on ISO 9705:1993. It describes the technical background of the test and gives information which may be used for determining a testing procedure for a specific scenario, or how results can be utilized in a total hazard analysis for the specified scenario.

Essais de réaction au feu — Essais dans une pièce en vraie grandeur pour les matériaux de revêtement intérieur — Partie 2: Données techniques et lignes directrices

General Information

Standards Content (Sample)

TECHNICAL ISO/TR

REPORT 9705-2

First edition

2001-05-01

Reaction-to-fire tests — Full-scale room

tests for surface products —

Part 2:

Technical background and guidance

Essais de réaction au feu — Essais dans une pièce en vraie grandeur pour

les matériaux de revêtement intérieur —

Partie 2: Données techniques et lignes directrices

Reference number

©

ISO 2001

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall not

be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In downloading this

file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat accepts no liability in this

area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation parameters

were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the unlikely event

that a problem relating to it is found, please inform the Central Secretariat at the address given below.

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic

or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or ISO's member body

in the country of the requester.

ISO copyright office

Case postale 56 � CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.ch

Web www.iso.ch

Printed in Switzerland

ii © ISO 2001 – All rights reserved

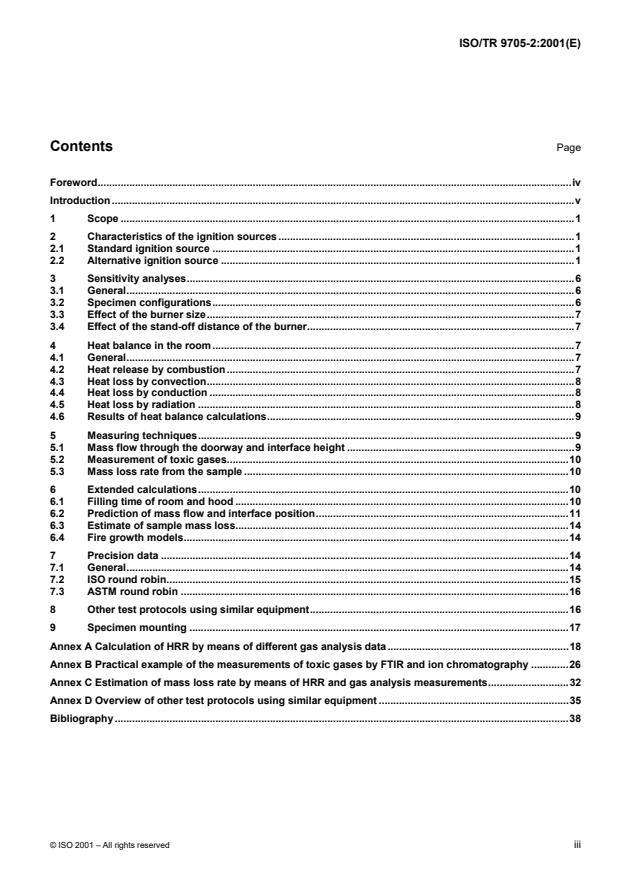

Contents Page

Foreword.iv

Introduction.v

1 Scope .1

2 Characteristics of the ignition sources .1

2.1 Standard ignition source .1

2.2 Alternative ignition source .1

3 Sensitivity analyses.6

3.1 General.6

3.2 Specimen configurations.6

3.3 Effect of the burner size.7

3.4 Effect of the stand-off distance of the burner.7

4 Heat balance in the room .7

4.1 General.7

4.2 Heat release by combustion.7

4.3 Heat loss by convection.8

4.4 Heat loss by conduction .8

4.5 Heat loss by radiation .8

4.6 Results of heat balance calculations.9

5 Measuring techniques.9

5.1 Mass flow through the doorway and interface height .9

5.2 Measurement of toxic gases.10

5.3 Mass loss rate from the sample .10

6 Extended calculations.10

6.1 Filling time of room and hood .10

6.2 Prediction of mass flow and interface position.11

6.3 Estimate of sample mass loss.14

6.4 Fire growth models.14

7 Precision data .14

7.1 General.14

7.2 ISO round robin.15

7.3 ASTM round robin .16

8 Other test protocols using similar equipment.16

9 Specimen mounting .17

Annex A Calculation of HRR by means of different gas analysis data.18

Annex B Practical example of the measurements of toxic gases by FTIR and ion chromatography .26

Annex C Estimation of mass loss rate by means of HRR and gas analysis measurements.32

Annex D Overview of other test protocols using similar equipment .35

Bibliography.38

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies (ISO

member bodies). The work of preparing International Standards is normally carried out through ISO technical

committees. Each member body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, governmental and non-governmental, in

liaison with ISO, also take part in the work. ISO collaborates closely with the International Electrotechnical

Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 3.

The main task of technical committees is to prepare International Standards. Draft International Standards adopted

by the technical committees are circulated to the member bodies for voting. Publication as an International

Standard requires approval by at least 75 % of the member bodies casting a vote.

In exceptional circumstances, when a technical committee has collected data of a different kind from that which is

normally published as an International Standard ("state of the art", for example), it may decide by a simple majority

vote of its participating members to publish a Technical Report. A Technical Report is entirely informative in nature

and does not have to be reviewed until the data it provides are considered to be no longer valid or useful.

Attention is drawn to the possibility that some of the elements of this part of ISO/TR 9705 may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO/TR 9705-2 was prepared by Technical Committee ISO/TC 92, Fire safety, Subcommittee SC 1, Fire initiation

and growth.

ISO 9705 consists of the following parts, under the general title Reaction-to-fire tests — Full-scale room tests for

surface products:

� Part 1: Full-scale test for surface products (currently published as ISO 9705:1993,Fire tests — Full-scale room

test for surface products)

� Part 2: Technical background and guidance [Technical Report]

iv © ISO 2001 – All rights reserved

Introduction

ISO 9705:1993 specifies a test method simulating a fire that starts under well-ventilated conditions, in a corner of a

small room with a single open doorway.

The method is intended to evaluate the contribution to fire growth provided by a surface product using a specified

ignition source. The method provides data for a specified ignition source for the early stages of a fire from ignition

up to flashover. ISO 9705:1993 also describes different measurement techniques inside and outside the room. This

part of ISO 9705 gives background information and support to the potential users of the test. It gives the user of the

test technical information on the ignition source, heat fluxes in the room from the burner, heat balance in the room

during a fire, aspects of smoke production and toxic gas species production, as well as aspects of modelling the

results of these tests. It gives the user the information necessary to select the testing procedure for specific projects

or regulations.

TECHNICAL REPORT ISO/TR 9705-2:2001(E)

Reaction-to-fire tests — Full-scale room tests for surface

products —

Part 2:

Technical background and guidance

1 Scope

This part of ISO 9705 provides guidance on ISO 9705:1993. It describes the technical background of the test and

gives information which may be used for determining a testing procedure for a specific scenario, or how results can

be utilized in a total hazard analysis for the specified scenario.

2 Characteristics of the ignition sources

2.1 Standard ignition source

The standard ignition source consists of a sandbox burner with dimensions of 0,17 m � 0,17 m. This source is used

in reference [1] (see Bibliography). An important characteristic of the ignition source is its heat transfer towards the

material. Figures 1 and 2 show a detailed mapped overview of the total heat flux towards the specimen and the gas

temperatures. The measurements are performed in an open wall configuration, at an energy release rate level of

100 kW [2]. These values will slightly change when the burner is located in a room environment. Figures 3 and 4

give the contours of a constant heat flux of 10 kW/m at different heat outputs of the burner and also where areas

of total heat flux are higher than a given value.

2.2 Alternative ignition source

One of the alternative heat sources is a box burner, with dimensions of 0,3 m � 0,3 m. It is described in

ASTM E603-98 [3]. Figures 5 and 6 give a detailed mapping of heat fluxes and gas temperatures for a burner

energy release rate of 160 kW [2]. Other heat sources may be more appropriate (see annex B of ISO 9705:1993).

Figure 7 gives results of heat fluxes towards the specimen for a heat source level of 40 kW and 160 kW, with

different gases (natural gases and a mixture of natural gas and toluene) [4]. Figures 8 and 9 show a comparison of

different burner sizes for contours of constant heat flux of 10 kW/m , at an energy release rate of 100 kW in an

open corner and for areas exposed to a certain irradiant heat flux [4].

Finally, an example is given of the difference between the total heat flux produced by a burner in a corner and a

wall position. Table 1 gives an overview of the total heat flux towards the floor and the total heat flux to the wall at

0,9 m and 1,5 m height for energy release rates of 40 kW and 160 kW using the alternative ignition source of

ISO 9705:1993. Results show that, for the corner position, heat flux levels are higher in almost all cases.

Figure 1 — Heat flux distribution at an energy Figure 2 — Gas temperature distribution 30 mm

release rate of 100 kW for the standard ignition from the wall at an energy release rate of 100 kW

source in an open corner for the standard ignition source in an open corner

2 © ISO 2001 – All rights reserved

NOTE Contours of 10 kW/m .

Figure 3 — Contours of constant heat flux for the standard ignition source in an open corner at different

irradiant heat flux levels

Figure 4 — Areas of total heat flux levels higher than a given value for the standard ignition source at

different irradiant heat flux levels in an open corner

Figure 5 — Heat flux distribution at 160 kW for the Figure 6 — Gas temperature distribution 30 mm

alternative ignition source in an open corner from the wall at 160 kW for the alternative ignition

source in an open corner

4 © ISO 2001 – All rights reserved

------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.