ISO 28002:2011

(Main)Security management systems for the supply chain — Development of resilience in the supply chain — Requirements with guidance for use

Security management systems for the supply chain — Development of resilience in the supply chain — Requirements with guidance for use

ISO 28002:2011 specifies requirements for a resilience management system in the supply chain to enable an organization to develop and implement policies, objectives, and programs, taking into account legal, regulatory and other requirements to which the organization subscribes; information about significant risks, hazards and threats that may have consequences to the organization, its stakeholders, and on its supply chain; protection of its assets and processes; and management of disruptive incidents.

Systèmes de management de la sécurité pour la chaîne d'approvisionnement — Développement de la résilience dans la chaîne d'approvisionnement — Exigences avec mode d'emploi

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 28002

First edition

2011-08-01

Security management systems for the

supply chain — Development of

resilience in the supply chain —

Requirements with guidance for use

Systèmes de management de la sécurité pour la chaîne

d'approvisionnement — Développement de la résilience dans la chaîne

d'approvisionnement — Exigences avec mode d'emploi

Reference number

©

ISO 2011

© ISO 2011

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2011 – All rights reserved

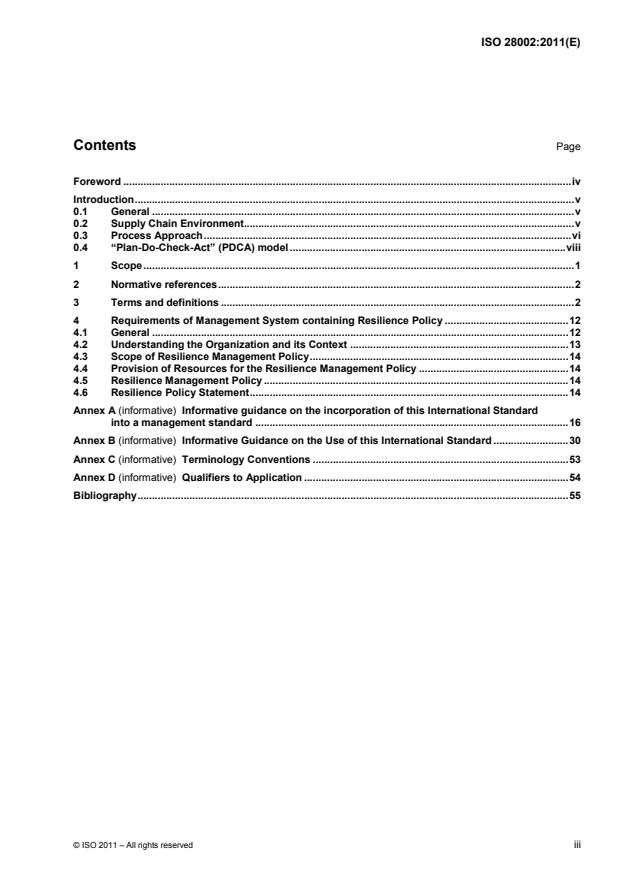

Contents Page

Foreword .iv

Introduction.v

0.1 General .v

0.2 Supply Chain Environment.v

0.3 Process Approach.vi

0.4 “Plan-Do-Check-Act” (PDCA) model .viii

1 Scope.1

2 Normative references.2

3 Terms and definitions .2

4 Requirements of Management System containing Resilience Policy .12

4.1 General .12

4.2 Understanding the Organization and its Context .13

4.3 Scope of Resilience Management Policy.14

4.4 Provision of Resources for the Resilience Management Policy .14

4.5 Resilience Management Policy .14

4.6 Resilience Policy Statement.14

Annex A (informative) Informative guidance on the incorporation of this International Standard

into a management standard .16

Annex B (informative) Informative Guidance on the Use of this International Standard .30

Annex C (informative) Terminology Conventions .53

Annex D (informative) Qualifiers to Application .54

Bibliography.55

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 28002 was prepared by Technical Committee ISO/TC 8, Ships and marine technology, in collaboration

with other relevant technical committees responsible for specific nodes of the supply chain.

This first edition cancels and replaces ISO/PAS 28002:2010.

iv © ISO 2011 – All rights reserved

Introduction

0.1 General

Organizations across the globe are rapidly developing risk management and resilience programs to address

uncertainty in achieving their objectives. There is a strong demand for standards and best practices, as

organizations are seeking assurance that their suppliers and the extended supply chain have planned for, and

taken steps to prevent and mitigate the threats and hazards to which they are exposed. To assure resilience

in the supply chain, organizations must engage in a comprehensive and systematic process of prevention,

protection, preparedness, mitigation, response, continuity and recovery.

The survivability of organizations within a supply chain depends largely on the resilience of their suppliers and

customers. As a result, incorporating resilience, and improving the resilience of an organization within the

supply chain, must be focused both within the organization and externally on its suppliers and customers.

During a supply chain disruption it must be emphasized that the exact nature of the disruption will probably not

be fully understood at first and may only become fully understood over time. As a result resilience plans and

policies developed should stress adaptation and continual evaluation of new information to ensure actions

being taken are appropriate. Supply chain disruptions of sufficient magnitude will most likely attract the news

media. Failure to properly manage news media relations can negatively impact resiliency response operations,

resulting in a loss of stakeholder confidence. This loss of confidence can result in loss of customers, increased

demand for information by government or financial organizations, and restrictions imposed by external

organizations. This International Standard has applicability in the private, not-for-profit, non-governmental, and

public sector environments. It is a management framework for action planning and decision making needed to

anticipate, prevent if possible, and prepare for and respond to a disruptive incident (emergency, crisis, or

disaster). When implemented within a management system it enhances an organization's capacity to manage

and survive the event, and take all appropriate actions to help ensure the organization's continued viability.

Regardless of the organization, its leadership has a duty to stakeholders to plan for its survival. The body of

this International Standard provides generic auditable criteria to establish, check, maintain, and improve

resilience policy when implemented in a management system to enhance prevention, preparedness

(readiness), mitigation, response, continuity, and recovery from disruptive incidents.

This International Standard is designed to be integral to ISO 28000. It also might possibly be integrated into

other management systems within an organization that follow the Plan-Do-Check-Act model. If third-party

independent certification is chosen, the certification will be applied to the overall management system

standard that incorporates this International Standard.

The integrated adaptive, proactive, and reactive resilience approach can leverage the perspectives,

knowledge, and capabilities of divisions and individuals within an organization. Because of the relatively low

probability and yet potentially high consequence nature of many natural, intentional, or unintentional threats

and hazards that an organization may face, an integrated approach allows an organization to establish

priorities that address its individual needs for risk management within an economically sound context.

0.2 Supply Chain Environment

Managing risks in the supply chain requires an understanding of the organization's environment as well as the

context of the global environment of the entire supply chain. Each node of the organization's supply chain

involves a set of risks and management processes of plan, source, make, deliver and return. All of these

management processes should be included in an organization's overall resilience policy. With this

understanding, an organization will define to which level or tier in their supply chain to include their resilience

program.

Global Environment

Organizations’ Environment

Suppliers’

Customers’

Environment

Environment

Organization

Supplier

Customer

Facing

Facing

Suppliers

(and outsource

Customers

manufacturing)

Internal Facing

Figure 1 — Resilience Management Policy in the Supply Chain (Source: Supply Chain Council 2007)

0.3 Process Approach

The management systems approach encourages organizations to analyse organizational and stakeholder

requirements and define processes that contribute to success. A management system can provide the

framework for continual improvement to increase the likelihood of enhancing security, preparedness,

response, continuity, and resilience. It provides confidence to the organization and its customers that the

organization is able to provide a safe and secure environment which fulfils organizational and stakeholder

requirements.

This International Standard adopts a process approach for establishing, implementing, operating, monitoring,

reviewing, maintaining, and improving an organization's resiliency to supply chain disruptions. An organization

needs to identify and manage many activities in order to function effectively. Any activity using resources and

managed in order to enable the transformation of inputs into outputs can be considered to be a process. Often

the output from one process directly forms the input to the next process.

The application of a system of processes within an organization, together with the identification and

interactions of these processes and their management, can be referred to as a “process approach”.

Figure 2 depicts the process approach for resilience management in the supply chain presented in this

International Standard which encourages its users to emphasize the importance of

a) understanding an organization's risk, security, preparedness, response, continuity, and recovery

requirements,

b) establishing a policy and objectives to manage risks,

c) implementing and operating controls to manage an organization's risks within the context of the

organization's objectives,

vi © ISO 2011 – All rights reserved

d) monitoring and reviewing the performance and effectiveness of the resilience management policy, and

e) continual improvement based on objective measurement.

Reassessment

Establish Program of risk program

and Apply Resources

Reassessment

of supply chain Define the Supply

Chain and Objectives

Reassessment

of risk sources

Identify Supply Chain

Risks

Quantify and Prioritize

Risks - Goals

Reassessment of

Reassessment

Execute Risk

management actions

of risk exposure

Treatment Programs

Monitor Supply Chain

Environment for Risks

Continuous risk

monitoring

Figure 2 — Process Approach for Resilience Management in the Supply Chain

0.3.1 Establish a Supply Chain Resilience Program and Apply Resources

⎯ Recognize supply chain risk management as a priority

⎯ Secure top management support for the program and

⎯ Secure resources necessary to execute the program

0.3.2 Define the Supply Chain and Resilience Objectives

⎯ Define the supply chain scope and map the supply chain

⎯ Define the objectives of managing risk in the subject supply chain

0.3.3 Identify Supply Chain Risks

⎯ Comprehensively review the supply chain to identify risks

⎯ Document identified risks to the extent possible

0.3.4 Quantify and Prioritize Risks

⎯ Quantify each risk in terms of likelihood of occurrence and potential impact

⎯ Use the quantification of the risks to prioritize the risks according to defined objectives

0.3.5 Execute Risk Treatment Programs

⎯ Develop risk management actions consistent with each risk's priority

⎯ Define each action's value in terms of reducing the likelihood and impact of the risk

⎯ Develop and execute an implementation plan for the identified actions

0.3.6 Monitor Supply Chain Environment for Risks

⎯ Continuously monitor the supply chain environment for risk events or precursors

⎯ When thresholds are triggered, execute applicable mitigation actions

⎯ Document results for after action review and program improvement

0.4 “Plan-Do-Check-Act” (PDCA) model

This International Standard is designed to be incorporated into a management system that uses the “Plan-Do-

Check-Act” (PDCA) model, which in turn will guide the implementation and execution of the resilience

management policy processes. Figure 3 illustrates how a management system can incorporate a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.