ISO 10835:2007

(Main)Direct reduced iron and hot briquetted iron — Sampling and sample preparation

Direct reduced iron and hot briquetted iron — Sampling and sample preparation

ISO 10835:2007 gives the underlying theory, the basic principles for sampling and preparation of samples, and the basic requirements for the design, installation and operation of sampling systems, for mechanical sampling, manual sampling and preparation of samples taken from a lot under transfer, to determine the chemical composition, moisture content and physical properties of the lot. The methods specified in this International Standard are applicable to both the loading and discharging of direct reduced iron (DRI) and hot briquetted iron (HBI), by means of belt conveyors and other ore handling equipment to which a mechanical sampler may be installed or where stopped-belt sampling may safely be conducted. In this International Standard, DRI includes both reduced pellets and reduced lump ores.

Minerais de fer préréduits et fer briqueté à chaud — Échantillonnage et préparation des échantillons

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 10835

Second edition

2007-02-15

Direct reduced iron and hot briquetted

iron — Sampling and sample preparation

Minerais de fer préréduits et fer briqueté à chaud — Échantillonnage et

préparation des échantillons

Reference number

©

ISO 2007

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2007

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2007 – All rights reserved

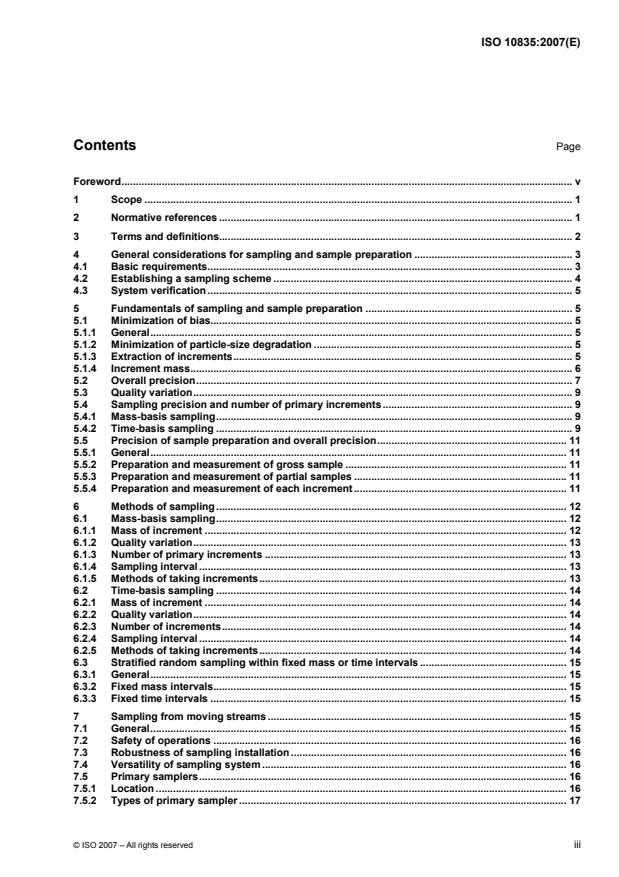

Contents Page

Foreword. v

1 Scope. 1

2 Normative references. 1

3 Terms and definitions. 2

4 General considerations for sampling and sample preparation . 3

4.1 Basic requirements. 3

4.2 Establishing a sampling scheme . 4

4.3 System verification. 5

5 Fundamentals of sampling and sample preparation . 5

5.1 Minimization of bias. 5

5.1.1 General. 5

5.1.2 Minimization of particle-size degradation . 5

5.1.3 Extraction of increments. 5

5.1.4 Increment mass. 6

5.2 Overall precision. 7

5.3 Quality variation. 9

5.4 Sampling precision and number of primary increments. 9

5.4.1 Mass-basis sampling. 9

5.4.2 Time-basis sampling. 9

5.5 Precision of sample preparation and overall precision. 11

5.5.1 General. 11

5.5.2 Preparation and measurement of gross sample . 11

5.5.3 Preparation and measurement of partial samples . 11

5.5.4 Preparation and measurement of each increment . 11

6 Methods of sampling. 12

6.1 Mass-basis sampling. 12

6.1.1 Mass of increment . 12

6.1.2 Quality variation. 13

6.1.3 Number of primary increments . 13

6.1.4 Sampling interval. 13

6.1.5 Methods of taking increments. 13

6.2 Time-basis sampling . 14

6.2.1 Mass of increment . 14

6.2.2 Quality variation. 14

6.2.3 Number of increments. 14

6.2.4 Sampling interval. 14

6.2.5 Methods of taking increments. 14

6.3 Stratified random sampling within fixed mass or time intervals . 15

6.3.1 General. 15

6.3.2 Fixed mass intervals. 15

6.3.3 Fixed time intervals. 15

7 Sampling from moving streams . 15

7.1 General. 15

7.2 Safety of operations . 16

7.3 Robustness of sampling installation. 16

7.4 Versatility of sampling system . 16

7.5 Primary samplers. 16

7.5.1 Location. 16

7.5.2 Types of primary sampler . 17

7.5.3 General design criteria for primary cutters . 17

7.5.4 Cutter aperture of primary sampler. 21

7.5.5 Cutter speed of primary sampler. 21

7.6 Secondary and subsequent samplers . 22

7.7 On-line sample preparation. 22

7.7.1 Arrangement for sample preparation. 22

7.7.2 Crushers. 22

7.7.3 Dividers. 22

7.7.4 Dryers. 27

7.8 Checking precision and bias . 27

7.9 Cleaning and maintenance. 27

7.10 Example of a flowsheet . 27

8 Sampling from stationary situations. 29

9 Stopped-belt reference sampling . 29

10 Sample preparation. 30

10.1 Fundamentals. 30

10.1.1 General. 30

10.1.2 Crushing and grinding. 30

10.1.3 Mixing. 30

10.1.4 Sample division. 30

10.1.5 Mass of divided sample. 31

10.1.6 Split use and multiple use of sample. 33

10.2 Method of constituting partial samples or a gross sample . 33

10.2.1 General. 33

10.2.2 Method of constitution for mass-basis sampling. 33

10.2.3 Method of constitution for time-basis sampling. 34

10.3 Mechanical methods of division. 34

10.3.1 Mechanical increment division. 34

10.3.2 Other mechanical-division methods . 35

10.4 Manual methods of division. 35

10.4.1 Manual increment division. 35

10.4.2 Fractional shoveling. 38

10.4.3 Manual riffle division method . 39

10.5 Preparation of test sample for physical testing. 40

10.6 Preparation of test sample for moisture determination. 40

10.7 Preparation of test sample for chemical analysis .41

10.7.1 Mass and particle size . 41

10.7.2 Preparation to – 250 µm. 41

10.7.3 Final preparation to – 160 µm .

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.