ISO 29942:2011

(Main)Prophylactic dams — Requirements and test methods

Prophylactic dams — Requirements and test methods

ISO 29942:2011 specifies the minimum requirements and test methods for prophylactic dams used to assist in the prevention of sexually transmitted infections.

Membranes prophylactiques — Exigences et méthodes d'essai

General Information

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 29942

First edition

2011-07-01

Prophylactic dams — Requirements and

test methods

Membranes prophylactiques — Exigences et méthodes d'essai

Reference number

©

ISO 2011

© ISO 2011

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2011 – All rights reserved

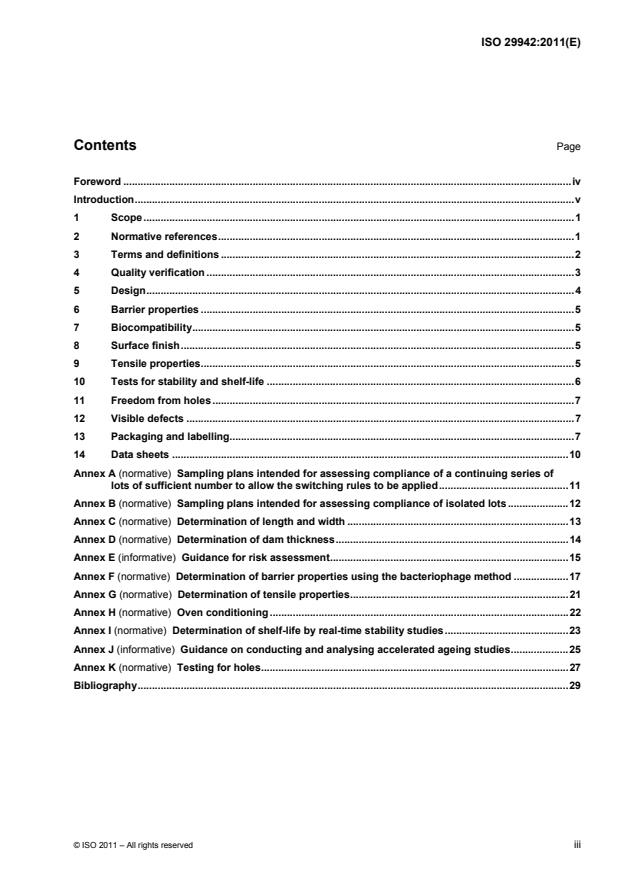

Contents Page

Foreword .iv

Introduction.v

1 Scope.1

2 Normative references.1

3 Terms and definitions .2

4 Quality verification .3

5 Design.4

6 Barrier properties .5

7 Biocompatibility.5

8 Surface finish.5

9 Tensile properties.5

10 Tests for stability and shelf-life .6

11 Freedom from holes.7

12 Visible defects .7

13 Packaging and labelling.7

14 Data sheets .10

Annex A (normative) Sampling plans intended for assessing compliance of a continuing series of

lots of sufficient number to allow the switching rules to be applied.11

Annex B (normative) Sampling plans intended for assessing compliance of isolated lots .12

Annex C (normative) Determination of length and width .13

Annex D (normative) Determination of dam thickness.14

Annex E (informative) Guidance for risk assessment.15

Annex F (normative) Determination of barrier properties using the bacteriophage method .17

Annex G (normative) Determination of tensile properties.21

Annex H (normative) Oven conditioning.22

Annex I (normative) Determination of shelf-life by real-time stability studies.23

Annex J (informative) Guidance on conducting and analysing accelerated ageing studies.25

Annex K (normative) Testing for holes.27

Bibliography.29

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 29942 was prepared by Technical Committee ISO/TC 157, Non-systemic contraceptives and STI barrier

prophylactics.

iv © ISO 2011 – All rights reserved

Introduction

A prophylactic dam is used to cover parts of the human body during sexual contact. The prophylactic dam

(hereinafter also referred to as “dam”) provides coverage to the external female genitalia or the anal area.

Non-porous, intact, polymer films have been demonstrated as barriers to the human immunodeficiency virus

(HIV) and other infectious agents responsible for the transmission of sexually transmitted infections (STls). To

be effective, it is essential that dams be free from holes and defects, have adequate physical properties so as

not to break during use, be correctly packaged to protect them during storage and be correctly labelled to

facilitate their use.

To be safe, it is essential that the dam and additive, dressing, individual packaging material or powder applied

to it neither contain nor liberate substances in amounts that are toxic, sensitizing, locally irritating or otherwise

harmful under normal conditions of storage or use.

Prophylactic dams are non-sterile medical devices; however, a clean environment is essential to minimize

microbiological and particulate contamination of the product during manufacturing and packaging. To ensure a

high-quality product, it is essential that it be designed and produced under a good quality management

system. See ISO 13485 and ISO 14971 for more details on risk management and quality management.

It is intended that manufacturers conduct stability tests to estimate the shelf-life of any new or modified design

before the product is placed on the market. These tests are intended to ensure that manufacturers have

adequate data to support shelf-life claims before products are placed on the market and that these data are

available for review by regulatory authorities, test laboratories and purchasers. They are also intended to limit

the need for third parties to conduct long-term stability studies. Real-time shelf-life studies are also initiated,

but not necessarily completed, prior to placing the product on the market.

INTERNATIONAL STANDARD ISO 29942:2011(E)

Prophylactic dams — Requirements and test methods

1 Scope

This International Standard specifies the minimum requirements and test methods for prophylactic dams used

to assist in the prevention of sexually transmitted infections.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 34-1, Rubber, vulcanized or thermoplastic — Determination of tear strength — Part 1: Trouser, angle and

crescent test pieces

ISO 37, Rubber, vulcanized or thermoplastic — Determination of tensile stress-strain properties

ISO 188, Rubber, vulcanized or thermoplastic — Accelerated ageing and heat resistance tests

ISO 2859-1:1999, Sampling procedures for inspection by attributes — Part 1: Sampling schemes indexed by

acceptance quality limit (AQL) for lot-by-lot inspection

ISO 4074, Natural latex rubber condoms — Requirements and test methods

ISO/TR 8550-1, Guidance on the selection and usage of acceptance sampling systems for inspection of

discrete items in lots — Part 1: Acceptance sampling

ISO/TR 8550-2, Guidance on the selection and usage of acceptance sampling systems for inspection of

discrete items in lots — Part 2: Sampling by attributes

ISO 10993-1, Biological evaluation of medical devices — Part 1: Evaluation and testing within a risk

management process

ISO 10993-5, Biological evaluation of medical devices — Part 5: Tests for in vitro cytotoxicity

ISO 10993-10, Biological evaluation of medical devices — Part 10: Tests for irritation and skin sensitization

ISO 10993-11, Biological evaluation of medical devices — Part 11: Tests for systemic toxicity

ISO 13485, Medical devices — Quality management systems — Requirements for regulatory purposes

ISO 14971, Medical devices — Application of risk management to medical devices

ISO 15223 (all parts), Medical devices — Symbols to be used with medical device labels, labelling and

information to be supplied

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 2859-1 and the following apply.

3.1

acceptance quality limit

AQL

quality level that is the worst tolerable process average when a continuing series of lots is submitted for

acceptance sampling

[ISO 2859-1:1999, definition 3.1.26]

3.2

consumer package

package intended for distribution to a consumer, containing one or more individual containers of prophylactic

dams

3.3

date of manufacture

date of formation of the prophylactic dam

3.4

expiry date

date after which the prophylactic dam cannot be used

3.5

prophylactic dam

piece of polymer film that prevents the transmission of micro-organisms, which can cause sexually transmitted

infections, and is designed to cover the anal area and/or the external female genitalia

3.6

identification number

number, or combination of numerals, symbols or letters used by a manufacturer on consumer packages to

uniquely identify the lot numbers of individual prophylactic dams contained in that package, and from which it

is possible to trace those lots through all stages of manufacturing, packaging and distribution

NOTE Whenever the consumer package contains only one kind of prophylactic dam, the identification number can be

the same as the lot number. However, if the consumer package contains several different types of prophylactic dam, for

instance prophylactic dams of different shapes or colours, the identification number is different from the lot numbers.

3.7

individual container

primary package containing a prophylactic dam

3.8

inspection level

relationship between lot size and sample size

NOTE For a description, see ISO 2859-1:1999, 10.1.

3.9

lot

collection of dams of the same design, colour, shape, size and formulation, manufactured at essentially the

same time, using the same process, raw materials of the same specifications, common equipment and

packed with the same lubricant and any other additive or dressing in the same type of individual container

NOTE This International Standard does not specify the size of a lot, but it is possible for a purchaser to do so as part

of the purchasing contract. Attention is drawn to the difficulties that can be associated with the distribution and control of

very large lots. The recommended maximum individual lot size for production is 500 000.

2 © ISO 2011 – All rights reserved

3.10

lot number

number or combination of numerals, symbols or letters used by the manufacturer to identify a lot of individually

packaged dams, and from which it is possible to trace that lot through all stages of manufacture up to

packaging

3.11

lot test

test to assess the conformity of a lot

NOTE A lot test can be limited to include only those parameters that can change from lot to lot.

3.12

non-visible hole

hole in a dam that is not visible under normal or corrected vision, but is detected by a suitable water leak test

3.13

sampling plan

specific plan that indicates the number of units of product from each lot which are to be inspected (sample

size or series of sample sizes) and the associated criteria for determining the acceptability of the lot

(acceptance and rejection numbers)

3.14

shelf-life

period of time from the date of manufacture over which the product is claimed to conform to the specified

requirements

3.15

visible hole

hole in the dam that is visible under normal or corrected vision before the dam is exposed to water during

testing for holes

3.16

visible defect

〈other than hole〉 permanent crease with adhesion of the film, or other materials embedded in the film

4 Quality verification

Dams are produced in large quantities. Inevitably there is some variation between indiv

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.