ISO 18894:2018

(Main)Coke — Determination of coke reactivity index (CRI) and coke strength after reaction (CSR)

Coke — Determination of coke reactivity index (CRI) and coke strength after reaction (CSR)

ISO 18894:2018 specifies the equipment and techniques used for determining lump-coke (nominal top size >20 mm) reactivity in carbon dioxide gas at elevated temperatures and its strength after reaction in carbon dioxide gas by tumbling in a cylindrical chamber. Main application is the testing of coke to be used in iron making blast furnaces (CRI~ 55). This standard can also be applied to other coke types (e.g. foundry coke), but limited precision is to be expected. Application to coke for non-iron making blast furnaces is beyond the scope of this document.

Coke — Détermination de l'indice de réactivité du coke (CRI) et de la résistance post-réactionelle du coke (CSR)

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 18894

Second edition

2018-02

Coke — Determination of coke

reactivity index (CRI) and coke

strength after reaction (CSR)

Coke — Détermination de l'indice de réactivité du coke (CRI) et de la

résistance post-réactionelle du coke (CSR)

Reference number

©

ISO 2018

© ISO 2018

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2018 – All rights reserved

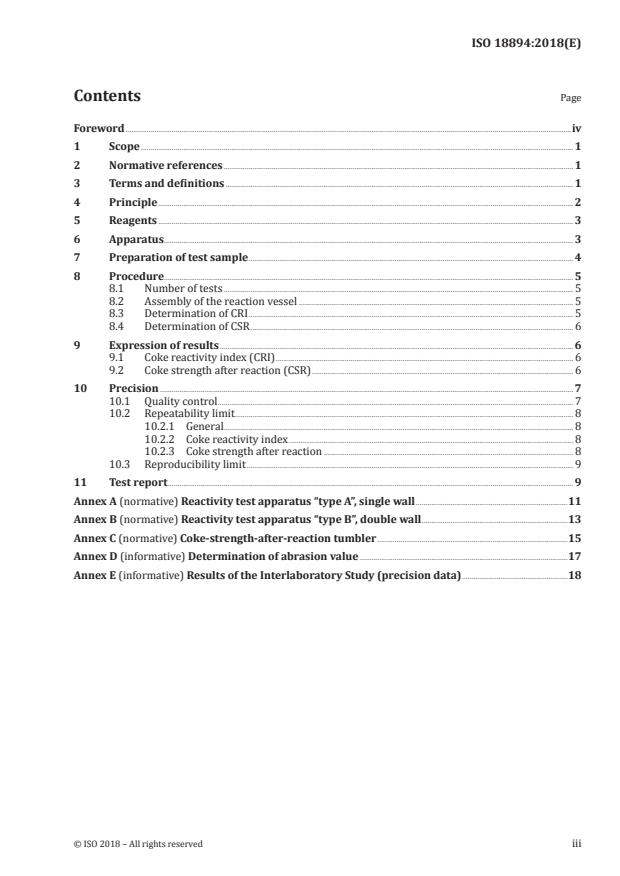

Contents Page

Foreword .iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Principle . 2

5 Reagents . 3

6 Apparatus . 3

7 Preparation of test sample . 4

8 Procedure. 5

8.1 Number of tests . 5

8.2 Assembly of the reaction vessel . 5

8.3 Determination of CRI . 5

8.4 Determination of CSR . 6

9 Expression of results . 6

9.1 Coke reactivity index (CRI) . 6

9.2 Coke strength after reaction (CSR) . 6

10 Precision . 7

10.1 Quality control . 7

10.2 Repeatability limit . 8

10.2.1 General. 8

10.2.2 Coke reactivity index . 8

10.2.3 Coke strength after reaction . 8

10.3 Reproducibility limit . 9

11 Test report . 9

Annex A (normative) Reactivity test apparatus “type A”, single wall .11

Annex B (normative) Reactivity test apparatus “type B”, double wall .13

Annex C (normative) Coke-strength-after-reaction tumbler .15

Annex D (informative) Determination of abrasion value .17

Annex E (informative) Results of the Interlaboratory Study (precision data) .18

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www .iso .org/ iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 27, Solid mineral fuels, Subcommittee

SC 3, Coke.

This second edition cancels and replaces the first edition (ISO 18894:2006), which has been technically

revised.

iv © ISO 2018 – All rights reserved

INTERNATIONAL STANDARD ISO 18894:2018(E)

Coke — Determination of coke reactivity index (CRI) and

coke strength after reaction (CSR)

1 Scope

This document specifies the equipment and techniques used for determining lump-coke (nominal top

size >20 mm) reactivity in carbon dioxide gas at elevated temperatures and its strength after reaction

in carbon dioxide gas by tumbling in a cylindrical chamber.

Main application is the testing of coke to be used in iron making blast furnaces (CRI~ < 33, CSR~ > 55).

This standard can also be applied to other coke types (e.g. foundry coke), but limited precision is to be

expected. Application to coke for non-iron making blast furnaces is beyond the scope of this document.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 579, Coke — Determination of total moisture

ISO 3310 (all parts), Test sieves — Technical requirements and testing

ISO 1213-2, Solid mineral fuels — Vocabulary — Part 2: Terms relating to sampling, testing and analysis

ISO 13909-5, Hard coal and coke — Mechanical sampling — Part 5: Coke — Sampling from moving streams

ISO 13909-6, Hard coal and coke — Mechanical sampling — Part 6: Coke — Preparation of test samples

ISO 18283, Hard coal and coke — Manual sampling

IEC 60584-1, Thermocouples — Part 1: EMF specifications and tolerances

IEC 60584-3, Thermocouples — Part 3: Extension and compensating cables — Tolerances and

identification system

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 1213-2 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

3.1

abrasion value

lack of resistance to abrasion of the coke after reaction with carbon dioxide in the CRI test, measured as

the percentage of a sample passing through a 0,5 mm sieve after tumbling under conditions specified in

this document

Note 1 to entry: See Annex D.

3.2

coke reactivity index

CRI

percentage weight loss of coke after reaction with carbon dioxide to form carbon monoxide under

conditions specified in this document

3.3

coke strength after reaction

CSR

strength of coke after reaction with carbon dioxide in the CRI test, measured as the percentage retained

on either a 10,0 mm or a 9,5 mm sieve after tumbling under conditions specified in this document

4 Principle

A test portion of the dried coke sample having a size range from 19,0 mm to 22,4 mm is heated in a

reaction vessel to 1 100 °C in a nitrogen atmosphere. For the test, the atmosphere is changed to carbon

dioxide for exactly 2 h. After the test, the reaction vessel is allowed to cool down to about 50 °C in a

nitrogen atmosphere. The comparison of the sample weight before and after the reaction determines

the coke reactivity index (CRI).

The reacted coke is treated in a specially designed tumbler for 600 revolutions for 30 min. The coke

strength after reaction (CSR) value is determined by sieving and weighing the amount of coke passing

through either a 10,0 mm or a 9,5 mm sieve.

An example of the arrangement of the test unit is shown in Figure 1.

NOTE During the development of this document, it was found that 10,0 mm and 9,5 mm sieves are both

commonly used for these types of test. When reacted coke is tumbled, abrasion usually takes place. Particles of

about 20 mm lose some edges, but they do not break into pieces. Therefore, it makes almost no difference if the

sieving after tumbling is made with a 10,0 mm or a 9,5 mm sieve, as the size of the coke pieces is either about

20 mm or 0 mm to 5 mm, but not in the range of 10 mm. This has been verified by experiments over a long period

of time. It has been shown that the difference in CSR using both sieve sizes is within the precision range of this

document.

2 © ISO 2018 – All rights reserved

Key

1 device for temperature recording 6 electrically heated furnace

2 thermocouple 7 gas-flow meters

3 single or double wall retort with perforated plate as sample holder 8 control valves

4 test portion 9 tumbler

5 layer of ceramic balls

a

Gas outlet to stack.

b

Gas inlet.

Figure 1 — Example of test unit arrangement

5 Reagents

5.1 Nitrogen, having a purity of >99,9 % by volume, dry and having a maximum oxygen and carbon

dioxide (CO + O ) concentration of 100 mg/kg.

2 2

5.2 Carbon dioxide, having a purity of >99,5 % by volume, dry and having an oxygen concentration

<100 mg/kg.

6 Apparatus

6.1 Electric furnace (see Annexes A and B), capable of housing the reaction-vessel assembly

containing the test portion and providing a uniform temperature of (1 100 ± 3) °C in the centre of the

test portion. The uniform temperature zone shall be at least three times longer than the sample height.

It is preferable that the furnace have independently controlled heating in three zones to achieve

uniformity of heating in the reaction vessel.

6.2 Reaction vessel (see Annexes A and B), constructed from heat-resistant steel or nickel alloy to

the dimensions required to fit inside the electric furnace selected for use.

The coke to be tested is placed on a perforated plate in the reaction ve

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.