ISO/TS 17104:2006

(Main)Rotary tool for threaded fasteners— Hydraulic impulse tools — Performance test method

Rotary tool for threaded fasteners— Hydraulic impulse tools — Performance test method

ISO/TS 17104:2006 specifies a laboratory performance test method for hydraulic impulse tools for installing threaded fasteners. It gives instructions on the procedure, performance parameters to test, how to evaluate and present the test data and justification for the test method. ISO/TS 17104:2006 is not intended as a routine in-plant inspection method.

Outils rotatifs pour éléments de fixation filetés — Outils hydraulique à impulsion — Méthode d'essai des caractéristiques de fonctionnement

General Information

Standards Content (Sample)

TECHNICAL ISO/TS

SPECIFICATION 17104

First edition

2006-04-15

Rotary tool for threaded fasteners —

Hydraulic impulse tools — Performance

test method

Outils rotatifs pour éléments de fixation filetés — Outils hydraulique à

impulsion — Méthode d'essai des caractéristiques de fonctionnement

Reference number

©

ISO 2006

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2006

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2006 – All rights reserved

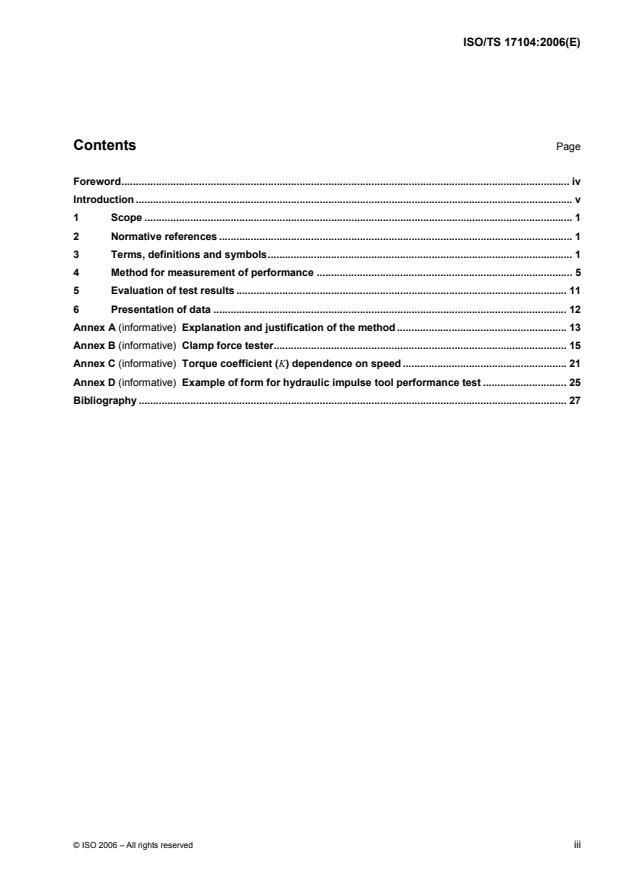

Contents Page

Foreword. iv

Introduction . v

1 Scope . 1

2 Normative references . 1

3 Terms, definitions and symbols. 1

4 Method for measurement of performance . 5

5 Evaluation of test results . 11

6 Presentation of data . 12

Annex A (informative) Explanation and justification of the method . 13

Annex B (informative) Clamp force tester. 15

Annex C (informative) Torque coefficient (K) dependence on speed . 21

Annex D (informative) Example of form for hydraulic impulse tool performance test . 25

Bibliography . 27

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

In other circumstances, particularly when there is an urgent market requirement for such documents, a

technical committee may decide to publish other types of normative document:

⎯ an ISO Publicly Available Specification (ISO/PAS) represents an agreement between technical experts in

an ISO working group and is accepted for publication if it is approved by more than 50 % of the members

of the parent committee casting a vote;

⎯ an ISO Technical Specification (ISO/TS) represents an agreement between the members of a technical

committee and is accepted for publication if it is approved by 2/3 of the members of the committee casting

a vote.

An ISO/PAS or ISO/TS is reviewed after three years in order to decide whether it will be confirmed for a

further three years, revised to become an International Standard, or withdrawn. If the ISO/PAS or ISO/TS is

confirmed, it is reviewed again after a further three years, at which time it must either be transformed into an

International Standard or be withdrawn.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO/TS 17104 was prepared by Technical Committee ISO/TC 118, Compressors and pneumatic tools,

machines and equipment, Subcommittee SC 3, Pneumatic tools and machines.

iv © ISO 2006 – All rights reserved

Introduction

The test method specified in this Technical Specification is designed to measure the overall performance and

capability of hydraulic impulse tools.

This ISO/Technical Specification is intended to give users of impulse tools a means for measuring and

comparing the performance of hydraulic impulse tools under controlled conditions.

Every effort has been made to specify all critical characteristics of the test fixtures conforming to this Technical

Specification. However, test results from different test fixtures can be affected by differences in dynamic

characteristics, thereby making direct comparisons difficult.

The ISO/TS can be used for comparing the torque capabilities of impulse tools. It has not so far been possible

to achieve acceptable reproducibility of the correlated torque scatter and it is hoped that data accumulated

through experience of using the ISO/TS enables improvements to be made when it is reviewed three years

after publication. In the meantime, when comparing the performances of different tools, quoted differences in

correlated torque scatter (as a percentage of mean correlated torque) of fewer than ten percentage points

should be viewed with caution/treated as insignificant, until verified by the potential user or purchaser of the

tools.

TECHNICAL SPECIFICATION ISO/TS 17104:2006(E)

Rotary tool for threaded fasteners — Hydraulic impulse tools —

Performance test method

1 Scope

This Technical Specification specifies a laboratory performance test method for hydraulic impulse tools for

installing threaded fasteners. It gives instructions on the procedure, performance parameters to test and how

to evaluate and present the test data.

Justification for the test method is found in Annex A.

The test method is not intended as a routine in-plant inspection method.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 2787, Rotary and percussive pneumatic tools — Performance tests

ISO 5393, Rotary tools for threaded fasteners — Performance test method

3 Terms, definitions and symbols

For the purposes of this document, the following terms, definitions and symbols apply.

3.1

hydraulic impulse tool

powered assembly tool for tightening threaded fasteners, which applies torque to a fastener in discontinuous

increments through a hydraulic impulse unit

3.1.1

automatic shut-off tool

powered assembly tool for tightening threaded fasteners, which is provided with a control mechanism or

system that shuts off or disconnects the power to the motor when a predetermined output level is attained

3.1.2

non shut-off tool

powered assembly tool for tightening threaded fasteners, which continues to apply torque impulses as long as

the throttle remains in the “on” position

3.2

standard deviation

s

measure of the dispersion (scatter) based on the mean-squared deviation from the arithmetic mean derived

from a sample of a statistical population

3.3

six sigma

6s

range of probability, plus and minus three standard deviations from the mean, derived from a sample of a

statistical population

NOTE For a normally distributed statistical population, 99,73 % of all members of that population are encompassed.

3.4

diameter

D

nominal diameter of a bolt

NOTE The diameter is expressed in millimetres.

3.5

angle

measure of the angular displacement through which a fastener is turned

NOTE The angle is expressed in degrees.

3.6

clamp force

F

C

result of the force achieved by turning a bolt in the tightening direction after the bolt head makes contact with

the joint bearing surface

NOTE The clamp force is expressed in newtons.

3.6.1

peak clamp force

F

CP

peak value of the clamp force measured during a tightening cycle

NOTE The peak clamp force is expressed in newtons.

3.6.2

target clamp force

F

CT

clamp force required to achieve the test torque when testing a hydraulic impulse tool on a test joint based on

Equation (1):

F=×TK/ D (1)

( )

CT T

where T is defined in 3.7.10, K is defined in 3.9.1, and D is defined in 3.4.

T

3.7

torque

product of the force turning the fastener and the perpendicular distance between the line of force and the

centre of the fastener

3.7.1

dynamic torque

T

D

torque recorded during the calibration of the test joint as described in 4.2.2 and 4.2.6

NOTE 1 For test joint analysis, dynamic torque is measured with an in-line, rotary torque and angle transducer, placed

between a continuous drive spindle and the socket/driver bit.

NOTE 2 Dynamic torque is expressed in newton-metres.

2 © ISO 2006 – All rights reserved

3.7.2

peak dynamic torque

T

DP

peak value of the dynamic torque recorded during a tightening cycle performed during the test joint calibration

procedure described in 4.2.6

3.7.3

correlated torque

T

C

torque derived from a peak clamp force measurement based on Equation (2):

TK=×D×F (2)

CCP

where K is defined in 3.9, F is defined in 3.6.1 and D is defined in 3.4

CP

NOTE The correlated torque is expressed in newton-metres.

3.7.4

mean correlated torque

T

C

arithmetic mean of a number of correlated torque readings on a specific joint as defined in 3.7.3

3.7.5

6s-correlated torque scatter

S

6s

predictable range of correlated torque over which a tool performs at a given setting using a single torque-rate

joint under controlled conditions

NOTE 1 For the practical purposes of this Technical Specification, 6s correlated torque scatter of a tool is the total

probable range of torque of a tool run on a single joint at the same setting of the tool torque adjustment.

NOTE 2 6s-correlated torque scatter is calculated according to 5.1.

3.7.6

6s-correlated torque scatter as a percentage of the mean correlated torque

S

6s,p

single numerical percentage value designating the correlated torque capability of a tool run on a single torque

rate joint under controlled conditions

NOTE 6s-correlated torque scatter as a percentage of the mean correlated torque is calculated according to 5.1.

3.7.7

combined mean correlated torque

T

C

comb

midpoint between the lowest and highest predictable correlated torque readings of a tool at a given setting

when tested on both test joints

NOTE The combined mean correlated torque is calculated according to 5.2.

3.7.8

combined correlated torque scatter

∆T

Ccomb

predictable range of correlated torque over which a tool performs, encompassing 99,73 % or more of all

possible correlated torque readings, taken on a range of joints of varying torque rates from a defined high

torque rate through a defined low torque rate

NOTE For the practical purposes of this Technical Specification, combined correlated torque scatter of a tool is the

total probable range of torque of a tool run on all joints used in practice at the same setting of the tool torque adjustment. It

is calculated according to 5.2.

3.7.9

correlated torque scatter as a percentage of combined mean correlated torque

single numerical value designating the correlated torque capability of a tool run on joints of varying torque rate,

from a defined high torque rate through a defined low torque rate at the same setting of the tool torque

adjustment

NOTE The correlated torque scatter as a percentage of combined mean correlated torque is calculated according

to 5.2.

3.7.10

test torque

T

T

torque level at which the tool's correlated torque scatter capability is determined, e.g., the torque level at

which the test is carried out

3.7.11

upper test torque

test torque equal to the upper limit of the defined torque adjustment range over which a tool's correlated

torque scatter capability is determined as described in 4.3.3.2

3.7.12

lower test torque

test torque equal to the lower limit of the defined torque adjustment

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.