ISO 14346:2013

(Main)Static design procedure for welded hollow-section joints — Recommendations

Static design procedure for welded hollow-section joints — Recommendations

ISO 14346:2013 gives guidelines for the design and analysis of welded uniplanar and multiplanar joints in lattice structures composed of circular (CHS), square (SHS) or rectangular (RHS) hollow sections, and of uniplanar joints in lattice structures composed of combinations of hollow sections with open sections under static loading. ISO 14346:2013 is applicable to CHS or RHS Y-, X- and K-joints and their multiplanar equivalents, gusset plate to CHS or RHS joints, open-section and RHS to CHS joints, and hollow-section to open-section joints.

Procédure statique de conception des joints soudés à section creuse — Recommandations

General Information

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 14346

First edition

2013-03-15

Static design procedure for

welded hollow-section joints —

Recommendations

Procédure statique de conception des joints soudés à section creuse —

Recommandations

Reference number

©

ISO 2013

© ISO 2013

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2013 – All rights reserved

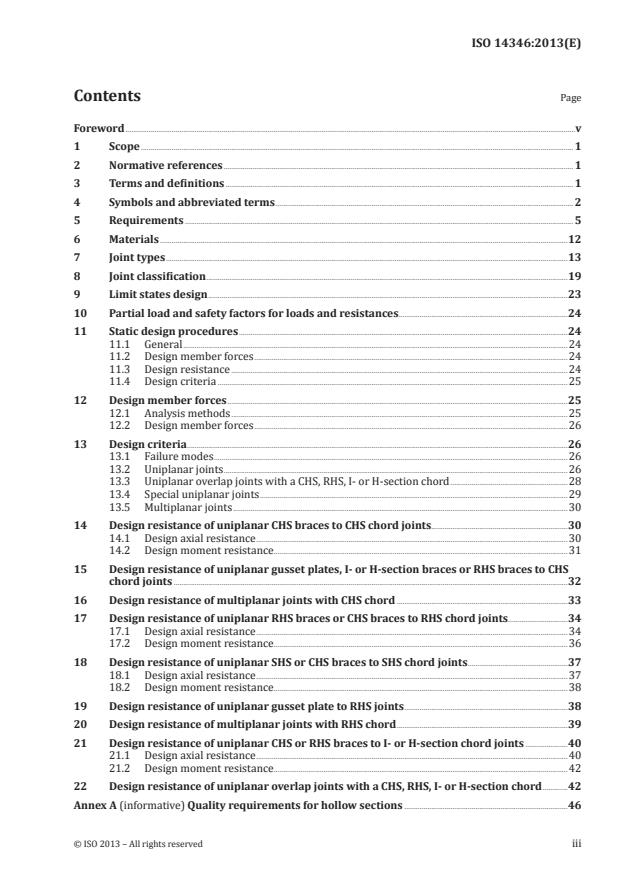

Contents Page

Foreword .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Symbols and abbreviated terms . 2

5 Requirements . 5

6 Materials .12

7 Joint types .13

8 Joint classification .19

9 Limit states design .23

10 Partial load and safety factors for loads and resistances .24

11 Static design procedures .24

11.1 General .24

11.2 Design member forces .24

11.3 Design resistance .24

11.4 Design criteria .25

12 Design member forces .25

12.1 Analysis methods .25

12.2 Design member forces .26

13 Design criteria .26

13.1 Failure modes .26

13.2 Uniplanar joints .26

13.3 Uniplanar overlap joints with a CHS, RHS, I- or H-section chord .28

13.4 Special uniplanar joints .29

13.5 Multiplanar joints .30

14 Design resistance of uniplanar CHS braces to CHS chord joints.30

14.1 Design axial resistance .30

14.2 Design moment resistance.31

15 Design resistance of uniplanar gusset plates, I- or H-section braces or RHS braces to CHS

chord joints .32

16 Design resistance of multiplanar joints with CHS chord .33

17 Design resistance of uniplanar RHS braces or CHS braces to RHS chord joints .34

17.1 Design axial resistance .34

17.2 Design moment resistance.36

18 Design resistance of uniplanar SHS or CHS braces to SHS chord joints .37

18.1 Design axial resistance .37

18.2 Design moment resistance.38

19 Design resistance of uniplanar gusset plate to RHS joints .38

20 Design resistance of multiplanar joints with RHS chord .39

21 Design resistance of uniplanar CHS or RHS braces to I- or H-section chord joints .40

21.1 Design axial resistance .40

21.2 Design moment resistance.42

22 Design resistance of uniplanar overlap joints with a CHS, RHS, I- or H-section chord .42

Annex A (informative) Quality requirements for hollow sections .46

Annex B (informative) Weld details .48

Annex C (informative) Partial safety factors on static strength .50

Bibliography .52

iv © ISO 2013 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International

Standards adopted by the technical committees are circulated to the member bodies for voting.

Publication as an International Standard requires approval by at least 75 % of the member bodies

casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 14346 was prepared by the International Institute of Welding, which has been approved as an

international standardizing body in the field of welding by the ISO Council.

Requests for official interpretations of any aspect of this International Standard should be directed to

the ISO Central Secretariat, who will forward them to the IIW Secretariat for an official response.

INTERNATIONAL STANDARD ISO 14346:2013(E)

Static design procedure for welded hollow-section joints —

Recommendations

1 Scope

This International Standard gives guidelines for the design and analysis of welded uniplanar and

multiplanar joints in lattice structures composed of circular (CHS), square (SHS) or rectangular (RHS)

hollow sections, and of uniplanar joints in lattice structures composed of combinations of hollow sections

with open sections under static loading. This International Standard is applicable to CHS or RHS Y-, X-

and K-joints and their multiplanar equivalents, gusset plate to CHS or RHS joints, open-section and RHS

to CHS joints, and hollow-section to open-section joints.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 630 (all parts), Structural steels

ISO 14347, Fatigue — Design procedure for welded hollow-section joints — Recommendations

ISO/TR 25901, Welding and related processes — Vocabulary

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 14347, ISO/TR 25901, and the

following apply.

3.1

chord face failure

chord plastification

plastic failure of the chord face or plastic failure of the chord cross-section

3.2

chord punching shear

crack initiation in a hollow-section chord wall leading to rupture of a brace member from the chord member

3.3

chord side wall failure

chord web failure

yielding, crushing or instability (crippling or buckling of the chord side wall or chord web) under the

relevant brace member

3.4

cross-section classification

identification of the extent to which the resistance (to axial compression or bending moment) and

rotation capacity of a cross-section are limited by its local buckling resistance

Note 1 to entry: For example, four classes are given in Eurocode 3 (see EN 1993-1-1) together with three limits on

diameter-to-thickness ratio for CHS or width-to-thickness ratio for RHS.

3.5

joint configuration

type or layout of the joint or joints in a zone within which the axes of two or more interconnected

members or elements intersect

3.6

local chord member yielding

local buckling of the chord connecting face in an overlapped joint

3.7

local yielding of overlapping brace

local yielding of overlapping plate

local yielding of brace

local yielding of plate

cracking in the weld or in a brace member, or local buckling of a brace member with reduced effective width

3.8

multiplanar joint

in a lattice structure, a joint connecting members situated in more than one plane

3.9

structural properties of a joint

resistance to forces and moments in the connected members, deformation and/or rotation capacity

3.10

uniplanar joint

in a lattice structure, a joint connecting members situated in a single plane

4 Symbols and abbreviated terms

A cross-sectional area of member i (i = 0, 1, 2)

i

A shear area of a chord member

s

b effective width of a plate or

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.