ISO 13424:2013

(Main)Surface chemical analysis — X-ray photoelectron spectroscopy — Reporting of results of thin-film analysis

Surface chemical analysis — X-ray photoelectron spectroscopy — Reporting of results of thin-film analysis

ISO 13424:2013 specifies the minimum amount of information required in reports of analyses of thin films on a substrate by XPS. These analyses involve measurement of the chemical composition and thickness of homogeneous thin films, and measurement of the chemical composition as a function of depth of inhomogeneous thin films by angle-resolved XPS, XPS sputter-depth profiling, peak-shape analysis, and variable photon energy XPS.

Analyse chimique des surfaces — Spectroscopie de photoélectrons X — Rapport des résultats de l'analyse de films minces

General Information

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 13424

First edition

2013-10-01

Surface chemical analysis — X-ray

photoelectron spectroscopy —

Reporting of results of thin-film analysis

Analyse chimique des surfaces — Spectroscopie de photoélectrons X

— Rapport des résultats de l’analyse de films minces

Reference number

©

ISO 2013

© ISO 2013

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2013 – All rights reserved

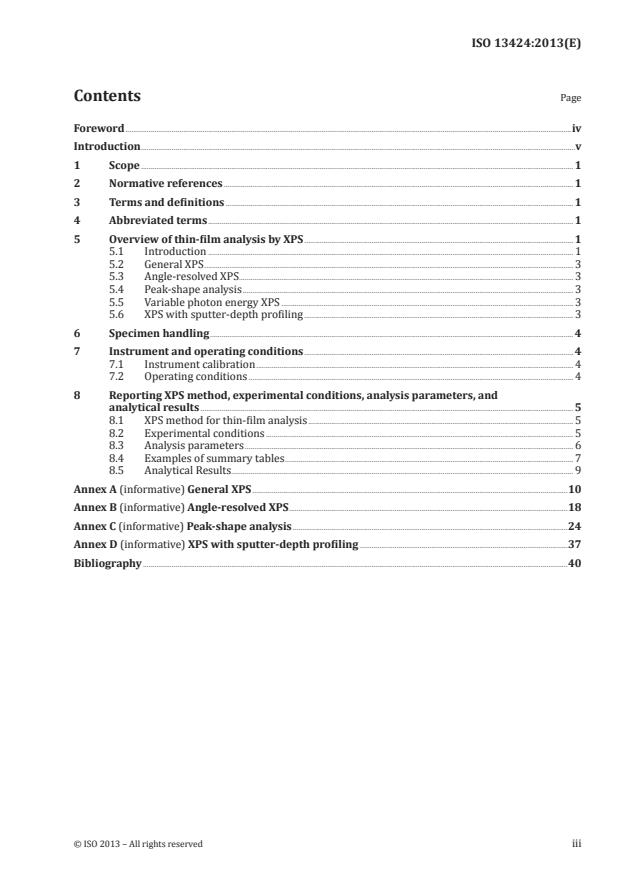

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Abbreviated terms . 1

5 Overview of thin-film analysis by XPS . 1

5.1 Introduction . 1

5.2 General XPS . 3

5.3 Angle-resolved XPS . 3

5.4 Peak-shape analysis . 3

5.5 Variable photon energy XPS . 3

5.6 XPS with sputter-depth profiling . 3

6 Specimen handling . 4

7 Instrument and operating conditions . 4

7.1 Instrument calibration . 4

7.2 Operating conditions . 4

8 Reporting XPS method, experimental conditions, analysis parameters, and

analytical results . 5

8.1 XPS method for thin-film analysis . 5

8.2 Experimental conditions . 5

8.3 Analysis parameters . 6

8.4 Examples of summary tables . 7

8.5 Analytical Results. 9

Annex A (informative) General XPS .10

Annex B (informative) Angle-resolved XPS .18

Annex C (informative) Peak-shape analysis .24

Annex D (informative) XPS with sputter-depth profiling .37

Bibliography .40

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 201, Surface chemical analysis, Subcommittee

SC 7, Electron spectroscopies.

iv © ISO 2013 – All rights reserved

Introduction

X-ray photoelectron spectroscopy (XPS) is widely used for the characterization of surfaces of materials,

especially for overlayer thin films on a substrate. The chemical composition of the near-surface region

of a thin film can be determined by XPS. If the film has a uniform thickness and the thickness is less than

about three times the mean escape depth (MED) for the measured photoelectrons, the film thickness and

the depth distribution of elements or chemical states of elements in the film can be determined by angle-

resolved XPS or peak-shape analysis . For thicker films, the depth distributions of elements in the film

can be obtained by sputter-depth profiling. Possible lateral inhomogeneities in film thicknesses or depth

profiles can be determined if the XPS system has sufficient lateral resolution. These XPS applications are

particularly valuable for characterizing thin-film nanostructures since the MED is typically less than

5 nm for many materials and common XPS measurement conditions.

Clauses 6 and 7 of this International Standard provide guidance to the operator of an XPS instrument in

making efficient measurements for determining meaningful chemical compositions and film thicknesses

for overlayer films on a substrate. Clause 8 of this International Standard shows the information to be

included in reports of the measurements and the analyses of the XPS data. Annex A, Annex B, Annex C,

and Annex D provide supplementary information on methods of data analysis for different types of XPS

measurements on thin-film samples.

INTERNATIONAL STANDARD ISO 13424:2013(E)

Surface chemical analysis — X-ray photoelectron

spectroscopy — Reporting of results of thin-film analysis

1 Scope

This International Standard specifies the minimum amount of information required in reports of

analyses of thin films on a substrate by XPS. These analyses involve measurement of the chemical

composition and thickness of homogeneous thin films, and measurement of the chemical composition

as a function of depth of inhomogeneous thin films by angle-resolved XPS, XPS sputter-depth profiling,

peak-shape analysis, and variable photon energy XPS.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 18115-1:2010, Surface chemical analysis — Vocabulary — Part 1: General terms and terms used in

spectroscopy

3 Terms and definitions

For the purposes of this document, the terms and definitions in ISO 18115-1:2010 apply.

4 Abbreviated terms

AES Auger electron spectroscopy

ARXPS Angle-resolved X-ray photoelectron spectroscopy

IMFP Inelastic mean free path

MED Mean escape depth

RSF Relative sensitivity factor

TRMFP Transport mean free path

XPS X-ray photoelectron spectroscopy

5 Overview of thin-film analysis by XPS

5.1 Introduction

XPS analyses of thin films on substrate can provide information on the variation of chemical composition

with depth and on film thicknesses. Several XPS methods can be used if the total film thickness is less than

three times the largest MED for the detected photoelectrons. The MED for particular photoelectrons is

a function of the IMFP and the emission angle of the photoelectrons with respect to the surface normal.

The IMFP depends on the photoelectron energy and the material. MED values can be obtained from a

[1]

database. A simple analytical formula for estimating MEDs has been published for emission angles

[2]

≤50°. For such emission angles, the MED is less than the product of the IMFP and the cosine of the

emission angle by an amount that depends on the strength of the elastic scattering of the photoelectrons

[2]

in the film. Both the IMFP and the strength versus depend on the chemical composition of the film.

The MED is typically less than 5 nm for many materials and common XPS instruments and measurement

conditions. If the effects of elastic scattering are neglected, the MED is given approximately by the

product of the IMFP and the cosine of the emission angle. The latter estimates of the MED can be

sufficient for emission angles larger than 50° although better estimates can be obtained, e.g. from the

[1]

database. If the total film thickness is greater than three times the largest MED, XPS can be used under

certain conditions (see Annex D) together with ion sputtering to determine the variation of chemical

composition with depth.

Table 1 provides a summary of the XPS methods which can be used for determining chemical composition

and/or film thickness. Some methods can be utilized for the characterization of single-layer or multiple-

layer thin films on a substrate and some methods can be used to determine the composition-depth

profile of a sample for which the composition is a function of depth measured from the surface (i.e.

where there is not necessarily an interface between two or more phases). The choice of method typically

depends on the type of sample and the analyst’s knowledge of the likely or expected morphology of

the sample (i.e. whether the sample can consist of a single overlayer film on a flat substrate, multiple

films on a flat substrate, or a sample with composition varying continuously with depth), whether the

total film thickness is less than or greater than the largest MED for the detected photoelectrons, and

the desired information (i.e. film composition or film thickness). The first three methods in Table 1 are

non-destructive while the final method is destructive (i.e. the composi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.