ISO 14900:2023

(Main)Plastics — Polyols for use in the production of polyurethanes — Determination of hydroxyl number

Plastics — Polyols for use in the production of polyurethanes — Determination of hydroxyl number

This document specifies two methods for the measurement of the hydroxyl number of polyols used as polyurethane raw materials. The hydroxyl content of polyols are determined to properly formulate polyurethane systems. Method A is primarily applicable to readily esterified polyether polyols. It is also intended for polyols which have significant steric hindrance, such as those based on sugars. Method B is intended for polyether polyols, polymer polyols and amine-initiated polyols, but can give low results for sterically hindered polyols. Other polyols can be analysed by these methods if precautions are taken to verify applicability. These methods can be used for research and for quality control and specification purposes.

Plastiques — Polyols pour la production de polyuréthanne — Détermination de l'indice d'hydroxyle

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 14900

Third edition

2023-12

Plastics — Polyols for use in the

production of polyurethanes —

Determination of hydroxyl number

Plastiques — Polyols pour la production de polyuréthanne —

Détermination de l'indice d'hydroxyle

Reference number

© ISO 2023

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

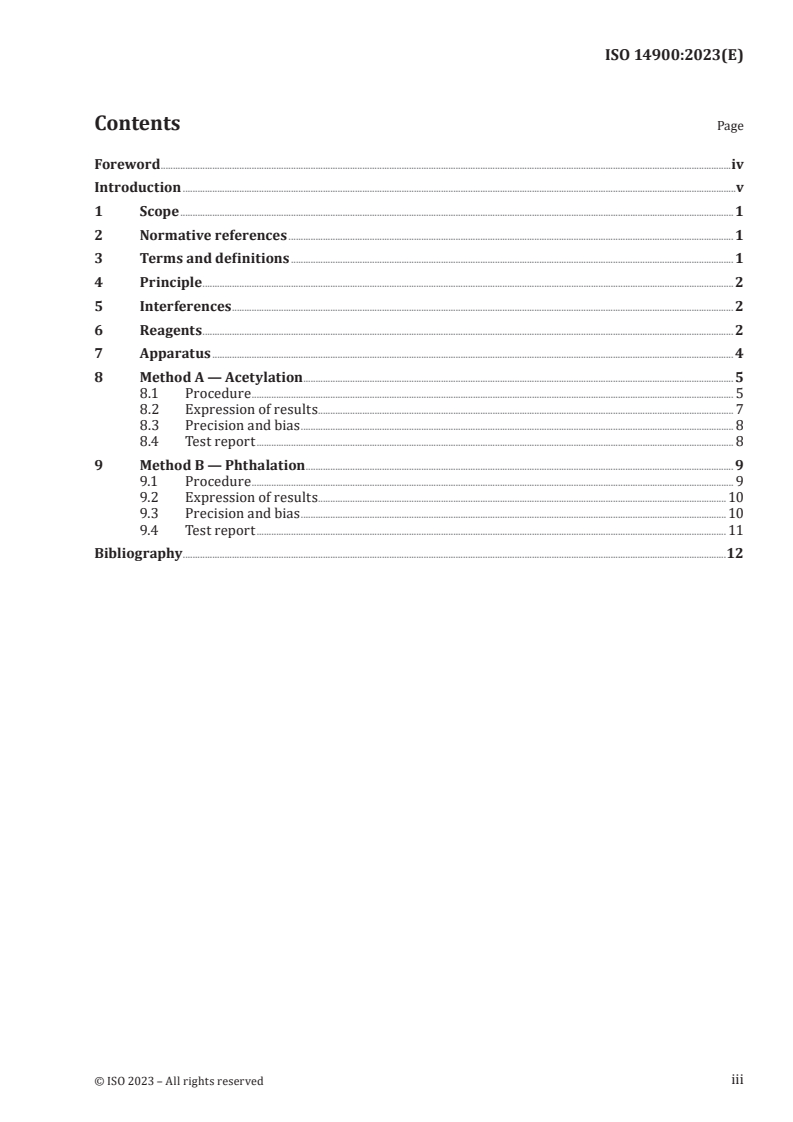

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Principle . 2

5 Interferences . 2

6 Reagents . 2

7 Apparatus . 4

8 Method A — Acetylation . 5

8.1 Procedure . 5

8.2 Expression of results . . 7

8.3 Precision and bias . 8

8.4 Test report . 8

9 Method B — Phthalation . 9

9.1 Procedure . 9

9.2 Expression of results . . 10

9.3 Precision and bias . 10

9.4 Test report . 11

Bibliography .12

iii

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO document should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use

of (a) patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed

patent rights in respect thereof. As of the date of publication of this document, ISO had not received

notice of (a) patent(s) which may be required to implement this document. However, implementers are

cautioned that this may not represent the latest information, which may be obtained from the patent

database available at www.iso.org/patents. ISO shall not be held responsible for identifying any or all

such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 61, Plastics, Subcommittee SC 12,

Thermosetting materials.

This third edition cancels and replaces the second edition (ISO 14900:2017), which has been technically

revised.

The main changes are as follows:

— the title has been changed to plural form to read: "Plastics — Polyols for use in the production of

polyurethanes — Determination of hydroxyl number";

— in 7.13, hotplate has been added as heating device;

— in 8.1.3, an oil bath has been added, in addition to a hot plate, as a heating device;

— in 8.3.1 and 9.3.1, precision and bias information have been updated;

— in 9.1.3, the information on hydrolysis of excess phthalic anhydride, and the water addition process

have been added.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

iv

Introduction

International Standards which deal with the determination of hydroxyl values of unsaturated-

polyester resins (ISO 2554), non-ionic surface active agents (ISO 4326, ISO 4327), binders for paints

and varnishes [ISO 4629 (all parts)] and industrial polyglycols (ISO 6796) have been published. The

two methods in this document are improved versions of imidazole-catalyzed procedures specifically

tailored to the determination of the hydroxyl number of many types of polyol, including those used in

the production of polyurethanes. Method A is especially suited to the determination of the hydroxyl

number of polyether polyols that may have steric hindrance, or are otherwise difficult to determine

by phthalation. Method B is a general method based on phthalation and is applicable to a wide range of

polyol types. Both of these methods are similar to procedures found in ASTM D4274.

v

INTERNATIONAL STANDARD ISO 14900:2023(E)

Plastics — Polyols for use in the production of

polyurethanes — Determination of hydroxyl number

WARNING — Persons using this document should be familiar with normal laboratory practice.

This document does not purport to address all of the safety problems, if any, associated with its

use. It is the responsibility of the user to establish appropriate safety and health practices and to

determine any national regulatory conditions prior to use.

1 Scope

This document specifies two methods for the measurement of the hydroxyl number of polyols used as

polyurethane raw materials.

The hydroxyl content of polyols are determined to properly formulate polyurethane systems. Method A

is primarily applicable to readily esterified polyether polyols. It is also intended for polyols which have

significant steric hindrance, such as those based on sugars. Method B is intended for polyether polyols,

polymer polyols and amine-initiated polyols, but can give low results for sterically hindered polyols.

Other polyols can be analysed by these methods if precautions are taken to verify applicability. These

methods can be used for research and for quality control and specification purposes.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 385, Laboratory glassware — Burettes

ISO 648, Laboratory glassware — Single-volume pipettes

ISO 760, Determination of water — Karl Fischer method (General method)

ISO 835, Laboratory glassware — Graduated pipettes

ISO 3696, Water for analytical laboratory use — Specification and test methods

ISO 4788, Laboratory glassware — Graduated measuring cylinders

ISO 6353-1, Reagents for chemical analysis — Part 1: General test methods

ISO 6353-2, Reagents for chemical analysis — Part 2: Specifications — First series

ISO 6353-3, Reagents for chemical analysis — Part 3: Specifications — Second series

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1

polyurethane

polymer prepared by the reaction of an organic di- or polyisocyanate with compounds containing two

or more hydroxyl groups

3.2

hydroxyl number

hydroxyl value

number of milligrams of potassium hydroxide equivalent to the hydroxyl content of 1 g of a test portion

4 Principle

4.1 Method A (Acetylation): A test portion is refluxed in a solution of acetic anhydride in pyridine

to acetylate the hydroxyl groups present; the reaction is catalyzed by imidazole. The excess reagent is

hydrolyzed with water and the resulting acetic acid is titrated with standardized sodium hydroxide

solution. The hydroxyl content is calculated from the difference in titration of the test portion and a

blank solution.

CAUTION — Acetic anhydride and pyridine are toxic and flammable. In addition, acetic anhydride

is corrosive. Take proper precautions when handling these reagents.

4.2 Method B (Phthalation): The hydroxyl groups in a test portion are esterified by refluxing with a

solution of phthalic anhydride in pyridine; the reaction is catalyzed by imidazole. The excess anhydride

is hydrolyzed with water and the phthalic acid formed is titrated with standardized sodium hydroxide

solution. The hydroxyl content is calculated from the difference in titration of the test portion and a

blank solution.

5 Interferences

5.1 Excess water will interfere by destroying part of the esterification reagent. If the sample contains

more than 0,2 % water, dry the sample with a reagent that will not add acidity or basicity to the sample.

5.2 Primary and secondary amines and long-chain fatty acids react with the reagent to form stable

compounds that will be included in the result.

6 Reagents

Reagent-grade chemicals shall be used in all determinations. Unless otherwise indicated, all reagents

shall conform to the specifications of ISO 6353-1, ISO 6353-2 and ISO 6353-3, although other grades

may be used provided that it is first determined that the reagent is of sufficiently high purity to permit

its use without lessening the accuracy of the determination.

Unless otherwise indicated, references to water shall be understood to mean grade 2 reagent water as

defined by ISO 3696.

6.1 Acetylation reagent (for method A).

6.1.1 Mix 127 ml of acetic anhydride with 1 000 ml of dry pyridine (6.7). Add 16 g of imidazole (6.3)

and swirl carefully to dissolve. Prepare the reagent fresh daily and keep it in a dark bottle. Do not use it

if it is darker than pale yellow.

6.1.2 Some laboratories have reported that dark, resinous solids have formed when the mixture

of pyridine and esterification reagent is heated. In that event, it has been found that preparing the

acetylation reagent with the addition of 0,4 % water in the pyridine (6.8) will correct the problem.

However, care should be taken that sufficient reagent is present to complete the reaction quantitatively.

See also 8.1.2.

CAUTION — Acetic anhydride and pyridine are eye, skin and respiratory irritants. Avoid bodily

contact with these reagents and use only in a well-ventilated area.

6.2 Phthalation reagent (for method B).

Weigh 116 g of phthalic anhydride into a 1 l brown bottle. Add 700 ml of pyridine (6.7) and shake

vigorously until dissolved. Add 16 g of imidazole and swirl carefully to dissolve. The reagent shall stand

overnight before use. Avoid prolonged exposure of the reagent to moisture in the air. Discard reagent

that develops a colour. In the blank titration as described in the procedure for method B, exactly 25 ml

of this reagent shall consume between 95 ml and 100 ml of 0,500 mol/l sodium hydroxide.

6.3 Imidazole, reagent grade or equivalent.

6.4 Hydrochloric acid, standard solution, 0,1 mol/l.

Prepare and standardize to four significant figures in accordance with good practice, using potassium

acid phthalate (6.6) as a primary standard. Determine and record the temperature at which the

standardization was performed. The concentration of the solution shall be corrected to the temperature

at which the determination is performed, as described in 6.9. This solution is required only if a

correction is to be applied for the presence of strong base in the sample being analysed.

6.5 Phenolphthalein indicator solution, 10 g/l.

Prepare a solution of 1 g of phenolphthalein in 100 ml of pyridine (6.7).

6.6 Potassium acid phthalate.

Use a certified primary standard.

6.7 Pyridine, reagent grade, containing less than 0,1 % water.

If purification is required, distil from phthalic anhydride, discarding the fraction boiling below 114 °C

to 115 °C.

6.8 Pyridine, containing from 0,30 % to 0,45 % water (used for special cases: see 6.1.2).

Determine the water content of the pyridine using ISO 760. Add the required amount of water. The

required volume of water to add per litre of pyridine may be calculated using Formula (1):

W = 4,0 − 9A (1)

where

W is the water to add, in ml;

A is the percent water already in the pyridine, in mass %.

6.9 Sodium hydroxide, standard solution, 0,5 mol/l.

Prepare and standardize to four significant figures in accordance with good practice. Determine and

record the temperature at which the standardization was performed. The factor for thermal expansion

of this solution is 0,000 14. For calculation of the hydroxyl content, the concentration of the solution

shall be corrected to the temperature at which the determination was calculated using Formula (2):

C = C + F (θ − θ) (2)

θ2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...