ISO 16091:2018

(Main)Space systems — Integrated logistic support

Space systems — Integrated logistic support

This document describes the set of management requirements needed to identify and provide logistic support, so the customer can operate and maintain a product in its operational environment for the expected lifetime. These requirements also aim, throughout the product life cycle, at implementing everything pertinent to the control of risks considered as critical for operational objectives. The management requirements are applicable to those activities necessary to design, develop, deliver, deploy and manage an organized and structured set of materials and software, services, processes and information dedicated to support the system throughout its life cycle. This document specifies management, studies, production activities, information management processes and tasks to meet the customer's need for logistic support. When viewed from the perspective of a specific project context, the requirements defined in this document are tailored to match the genuine requirements of a particular profile and circumstances of a project. NOTE Tailoring is the process by which individual requirements of specifications, standards and related documents are evaluated, and made applicable to a specific project by selection, and in some exceptional cases, modification of existing or addition of new requirements.

Systèmes spatiaux — Soutien logistique intégré

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 16091

Second edition

2018-08

Space systems — Integrated logistic

support

Systèmes spatiaux — Soutien logistique intégré

Reference number

©

ISO 2018

© ISO 2018

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2018 – All rights reserved

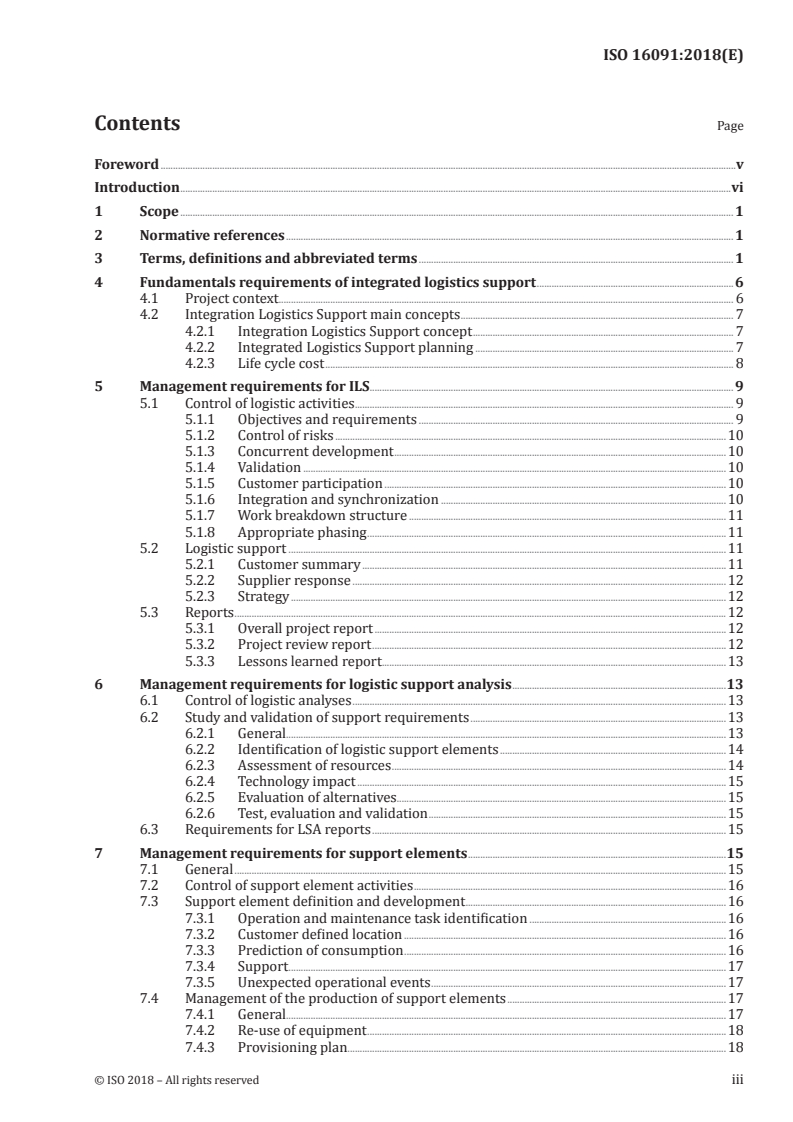

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms, definitions and abbreviated terms . 1

4 Fundamentals requirements of integrated logistics support . 6

4.1 Project context. 6

4.2 Integration Logistics Support main concepts . 7

4.2.1 Integration Logistics Support concept . 7

4.2.2 Integrated Logistics Support planning . 7

4.2.3 Life cycle cost . 8

5 Management requirements for ILS . 9

5.1 Control of logistic activities . 9

5.1.1 Objectives and requirements . 9

5.1.2 Control of risks .10

5.1.3 Concurrent development .10

5.1.4 Validation .10

5.1.5 Customer participation .10

5.1.6 Integration and synchronization .10

5.1.7 Work breakdown structure .11

5.1.8 Appropriate phasing .11

5.2 Logistic support .11

5.2.1 Customer summary .11

5.2.2 Supplier response .12

5.2.3 Strategy .12

5.3 Reports .12

5.3.1 Overall project report .12

5.3.2 Project review report .12

5.3.3 Lessons learned report . .13

6 Management requirements for logistic support analysis .13

6.1 Control of logistic analyses .13

6.2 Study and validation of support requirements .13

6.2.1 General.13

6.2.2 Identification of logistic support elements .14

6.2.3 Assessment of resources .14

6.2.4 Technology impact .15

6.2.5 Evaluation of alternatives.15

6.2.6 Test, evaluation and validation .15

6.3 Requirements for LSA reports .15

7 Management requirements for support elements .15

7.1 General .15

7.2 Control of support element activities .16

7.3 Support element definition and development .16

7.3.1 Operation and maintenance task identification .16

7.3.2 Customer defined location .16

7.3.3 Prediction of consumption .16

7.3.4 Support .17

7.3.5 Unexpected operational events .17

7.4 Management of the production of support elements .17

7.4.1 General.17

7.4.2 Re-use of equipment .18

7.4.3 Provisioning plan . .18

7.4.4 Support equipment acquisition plan .18

7.4.5 Support facilities plan.18

7.4.6 Packaging, handling, storage and transportation plan .18

7.4.7 Software support plan . .19

7.4.8 Technical assistance plan .19

7.4.9 Manpower management .19

7.4.10 Training plan .19

8 ILS requirements for information management .20

8.1 Integration of logistic support into overall information/documentation management .20

8.2 Data processing .20

8.2.1 General.20

8.2.2 Logistic support data items .20

8.2.3 logistic support data maturity .20

8.2.4 ILS performance reports .20

8.2.5 Logistic support data .21

8.2.6 Validated data .21

8.2.7 Data flow .21

8.2.8 Data control .22

8.3 Information system installation/operation .22

8.3.1 Media and interface requirements .22

8.3.2 Information system .22

Bibliography .23

iv © ISO 2018 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www .iso .org/iso/foreword .html.

This document was prepared by Technical Committee ISO/TC 20 Aircraft and space vehicles,

Subcommittee SC 14, Space systems and operations.

This second edition cancels and replaces the first edition (ISO 16091:2002), which has been technically

revised.

The main changes compared to the previous edition are focused on the update of concepts.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/members .html.

Introduction

The Integrated Logistics Support (ILS) programme is the integrated planning and action of a number

of disciplines in concert with one another to assure system availability. The impact of ILS is often

measured in terms of metrics such as reliability, maintainability, availability, and testability (RMAT),

and sometimes system safety. The ILS programme is justified in the space context by improvement

of current practices in terms of development of material resources and services essential to support

operation and maintenance and to control associated operational risks, particularly in terms of

utilization cost and availability.

It is also justified by heightening the awareness of all the programmes and project participants of

the need for cost effective preparation, transfer, and management of information needed to operate,

maintain, resupply and dispose of a product. This is as well as ensuring the recording of unscheduled

events in order to perform essential support analyses.

The ILS approach differs for different types of space programmes or projects and this document permits

appropriate tailoring. Consequently, the requirements in this document are applied at the management

level, with identification of the objectives to be achieved, rather than with methods and techniques to

be implemented to achieve these objectives.

These objectives include:

a) the participation of the supportability objectives to the system design;

b) the optimization of the operational and maintenance concepts;

c) the identification of the required logistic support elements;

d) the timely delivery of the logistic support elements; and

e) the determination of the system resilience to unscheduled operational events.

Logistic support is not a new concept. For many centuries, military organizations have utilized logistic

support in one form or another to coordinate the activities and resources involved in the maintenance

and operation of militarized systems and their support elements, aiming at minimizing operational

risks and total life cycle cost while achieving all mission-critical requirements. Integration of logistic

support into the programme or project is for coordinating, throughout the life cycle, the activities and

resources involved in the preparation and optimization of the system and its support elements, aiming

at minimum overall life cycle cost, according to the requirements and operational risks.

The advantages and increased efficiency resulting from integrating the logistic support requires that

the logistic support functions be addressed starting from the inception of the system. It also requires

that an integrated approach be established between the design and development of the system and the

operational requirements to be fulfilled. This approach is designed to ensure the ability to deliver on

time and in proper quantity, material resources and services to deploy, operate, maintain and upgrade

the system throughout its utilization phase, within cost requirements, in its operational environment.

It also helps to ensure that the capability of the organization and resources dedicated to define, collect,

manage and handle the information required to control the logistic support functions throughout the

system life cycle from the feasibility phase to the disposal phase are fully developed.

vi © ISO 2018 – All rights reserved

INTERNATIONAL STANDARD ISO 16091:2018(E)

Space systems — Integrated logistic support

1 Scope

This document describes the set of management requirements needed to identify and provide logistic

support, so the customer can operate and maintain a product in its operational environment for the

expected lifetime.

These requirements also aim, throughout the product life cycle, at implementing everything pertinent

to the control of risks considered as critical for operational objectives.

The management requirements are applicable to those activities necessary to design, develop, deliver,

deploy and manage an organized and structured set of materials and software, services, processes and

information dedicated to support the system throughout its life cycle.

This document specifies management, studies, production activities, information management

processes and tasks to meet the customer's need for logistic support.

When viewed from the perspective of a specific project context, the requirements defined in this

document are tailored to match the genuine requirements of a particular profile and circumstances of

a project.

NOTE Tailoring is the process by which individual requirements of specifications, standards and related

documents are evaluated, and made applicable to a specific project by selection, and in some exceptional cases,

modification of existing or addition of new requirements.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 14300-1, Space systems — Programme management — Part 1: Structuring of a project

ISO 10789, Space systems — Programme management — Information and documentation management

ISO 10795, Space systems — Programme management and quality — Vocabulary

3 Terms, definitions and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions given in ISO 10795 and the

following apply. ISO and IEC maintain terminological databases for use in standardization at the

following addresses:

— ISO Online browsing platform: available at https: //www .iso .org/obp

— IEC Electropedia: available at http: //www .electropedia .org/

3.1.1

availability

ability of an item to be in a state to perform a required function under given conditions at a given instant

of time or over a given time interval, assuming that the required external resources are provided

Note 1 to entry: This ability depends on the combined aspects of the reliability performance, the maintainability

performance and the maintenance support performance.

Note 2 to entry: Required external resources, other than maintenance resources, do not affect the availability

performance of the item.

Note 3 to entry: In French, the term “disponibilité” is used to denote both the performance and the measure.

3.1.2

configuration

interrelated functional and physical characteristics of a product or service defined in configuration

management

[SOURCE: ISO 10007:2017, modified — definition previously stated “.defined in configuration

information”]

3.1.3

customer

person or organization that could or does receives a product or a service that is intended for or required

by this person or organization

EXAMPLE Consumer, client, end-user, retailer, receiver of product or service from an internal process,

beneficiary and purchaser.

Note 1 to entry: A customer can be internal or external to the organization.

[SOURCE: ISO 9000:2015, 3.2.4]

3.1.4

data

information represented in a manner suitable for automatic processing

[SOURCE: IEC 60050-701-01-11:1992]

3.1.5

dependability

ability to perform as and when required

Note 1 to entry: Dependability characteristics include availability and its inherent or external influencing factors,

such as: reliability, fault tolerance, recoverability, integrity, security, maintainability, durability, and maintenance

support.

Note 2 to entry: Dependability is also used descriptively as an umbrella term for the time-related quality

characteristics of a product or service, and it may also be expressed as a grade, degree, confidence or probability

of fulfilling a defined set of characteristics.

Note 3 to entry: Specifications for dependability characteristics typically include the function the product is

required to perform; the time for which it is required that that performance be sustained; and the conditions

of storage, use and maintenance. Requirements for safety, efficiency and economy throughout the life cycle may

also be included.

[SOURCE: IEC 60050-192-01-22:1992]

3.1.6

document

information and its supporting medium

EXAMPLE Record, specification, procedure document, drawing, report, standard.

2 © ISO 2018 – All rights reserved

Note 1 to entry: The medium can be paper, magnetic, electronic or optical computer disc, photograph or master

sample, or a combination thereof.

Note 2 to entry: A set of documents, for example specifications and records, is frequently called “documentation”.

Note 3 to entry: Some requirements (e.g. the requirement of readability) relate to all types of documents, however

there can be different requirements for specifications (e.g. the requirement that they be revision controllable)

and records (e.g. the requirement that they be retrievable).

[SOURCE: ISO 9000:2015, 3.8.5]

3.1.7

down time

time interval during which an item is in a down state

Note 1 to entry: Down time excludes disabled time due to lack of external resources, but includes maintenance time.

[SOURCE: IEC 60050-192-02-21:1992]

3.1.8

function

intended effect of a system, subsystem, product or part

3.1.9

implementation document

formal response from a supplier to the customer’s Project Requirements Document describing how all

requirements will be met

[SOURCE: EN 16601-00-01:2015]

3.1.10

industrial organization

identity, interfaces and responsibilities of all participants in the supplier chain for a project

3.1.11

mean time to restoration

MTTR

DEPRECATED: mean time to repair

DEPRECATED: mean time to recovery

expectation of the time to restoration

[SOURCE: IEC 60050-192-07-23:1992]

3.1.12

mission analysis

assessment of the mission as a result of the project with exploration of concepts conforming to

expressed objectives to be reached, such as performance, cost, and schedule

3.1.13

process

set of interrelated or interacting activities that use inputs to deliver an intended result

Note 1 to entry: Whether the “intended result” of a process is called output, product or service, depends on the

context of the reference.

Note 2 to entry: Inputs to a process are generally outputs of other processes and outputs of a process are generally

the inputs to other processes.

Note 3 to entry: Two or more interrelated and interacting processes in series can also be referred to as a process.

Note 4 to entry: Processes in an organization are generally planned and carried out under controlled conditions

to add value.

Note 5 to entry: A process where the conformity of the resulting output cannot be readily or economically

validated is frequently referred to as a “special process”.

Note 6 to entry: This constitutes one of the common terms and core definitions for ISO management system

standards given in Annex SL of the Consolidated ISO Supplement to the ISO/IEC Directives, Part 1. The original

definition has been modified to prevent circularity between process and output, and Notes 1 to 5 to entry have

been added.

[SOURCE: ISO 9000:2015, 3.4.1]

3.1.14

programme

group of projects managed in a coordinated way to obtain benefits not available from managing them

individually

[SOURCE: ISO 14300-1:2011, 3.2]

3.1.15

project

unique process, consisting of a set of coordinated and controlled activities with start and finish dates,

undertaken to achieve an objective conforming to specific requirement, including the constraints of

time, cost and resources

Note 1 to entry: An individual project can form part of a larger project structure and generally has a defined start

and finish date.

Note 2 to entry: In some projects the objectives and scope are updated and the product or service characteristics

defined progressively as the project proceeds.

Note 3 to entry: The output of a project can be one or several units of product or service.

Note 4 to entry: The project’s organization is normally temporary and established for the lifetime of the project.

Note 5 to entry: The complexity of the interactions among project activities is not necessarily related to the

project size.

[SOURCE: ISO 9000:2015, 3.4.2]

3.1.16

project phase

part of a total project during which activities are performed to attain a designated objective as one of a

series of distinct steps in carrying out a project that together constitute the project life cycle

3.1.17

project requirements documents

documents, including all normative references, that establish requirements

Note 1 to entry: Examples of project requirements documents include, but are not limited to, standards,

management specifications, technical specifications, statements of work and data requirements lists.

Note 2 to entry: This does not include the contract and associated terms and conditions.

3.1.18

resource

any physically or conceptually identifiable entity whose use and state at any time can be unambiguously

determined

[SOURCE: IEC 60050-715-02-01:1992]

3.1.19

space element

product or set of products intended to be operated in outer space

4 © ISO 2018 – All rights reserved

3.1.20

specification

document stating requirements

EXAMPLE Quality manual, quality plan, technical drawing, procedure document, work instruction.

Note 1 to entry: A specification can be related to activities (e.g. procedure document, process specification and

test specification), or products (e.g. product specification, performance specification and drawing).

Note 2 to entry: It can be that, by stating requirements, a specification additionally is stating results achieved by

design and development and thus in some cases can be used as a record.

[SOURCE: ISO 9000:2015, 3.8.7]

3.1.21

supplier

organization that provides a product or a service

EXAMPLE Producer, distributor, retailer or vendor of a product or a service.

Note 1 to entry: A supplier can be internal or external to the organization.

Note 2 to entry: In a contractual situation a supplier is sometimes called "contractor".

[SOURCE: ISO 9000:2015]

3.1.22

support elements

hardware and software products, together with the necessary human resources, which are essential to

enable the system to achieve its required performance from delivery to disposal

EXAMPLE Electrical ground support equipment.

Note 1 to entry: Some items, during different phases of the project, can start as part of the system and later,

modified as necessary, become support elements.

3.1.23

system

set of interdependent elements constituted to achieve a given objective by performing a specified

function

Note 1 to entry: The system is considered to be separated from the environment and other external systems by

an imaginary surface which cuts the links between them and the considered system. Through these links, the

system is affected by the environment, is acted upon by external systems, or acts itself on the environment or the

external systems.

[SOURCE: ISO 14620-1:2002, 3.1.28]

3.1.24

system of systems

integration of existing and/or new systems into an over-arching system with capabilities that are

greater than the sum of the capabilities of the constituent component systems

3.1.25

system safety

application of engineering and management principles, criteria, and techniques to optimize all aspects

of safety within the constraints of operational effectiveness, time, and cost throughout all phases of the

system life cycle

3.1.26

task

specific piece of work to be done

3.1.27

work breakdown structure

hierarchical representation of the activities necessary to complete a project

[SOURCE: EN 16601-00-01:2015, 2.3.230]

3.1.28

work package

group of related tasks that are defined down to the lowest level within a work breakdown structure

Note 1 to entry: Grouping of tasks related to a same product and a same supplier.

[SOURCE: ISO 16601-00-01:2015]

3.2 Abbreviations

The following abbreviated terms are defined and used within this document.

BITE built-in test equipment

ILS integrated logistic support

LSA logistic support analysis

OEM original equipment manufacturer

PHST packaging, handling, storage and transport

WBS work breakdown structure

4 Fundamentals requirements of integrated logistics support

4.1 Project context

The following aspects shall be considered:

a) Logistic support shall be provided throughout the utilization phase and requires, especially

throughout the early phases of the project or programme, the management of specific activities of

design and development (called logistic activities), in close relation with the other activities, such

as safety, dependability, and quality assurance (SD&QA).

NOTE In the context of this document, safety is synonymous with system safety.

b) Integrated logistics support (ILS) activities shall be part of the project or programme activities and

integrated into its phasing and planning, in order to ensure their consideration in the development

of the system. These activities shall be adapted depending on the project or programme

organizational and technical effort to address the identified critical items.

c) In particular, the system design activities, during the initial system development phase and

design change activities during the system utilization phase, shall lead to a concurrent definition

of the system and its associated support elements. The system definition shall be based on initial

operational and maintenance concepts, in order to integrate the customer’s requirements. The

system definition effort shall be started as soon as possible, in order to ensure self-consistency.

d) The management of logistic activities is therefore integrated into the project or programme

management requirements: this document takes into consideration the existence of a set of space

standards and complements it by developing the ILS requirements.

6 © ISO 2018 – All rights reserved

e) The management of logistic activities throughout the system life cycle shall clearly demonstrate:

i) that the safety, dependability and quality assurance criteria are taken into account within the

product’s operational environment of use;

ii) the suitability, coherence and continuity of the logistic support; and

iii) the ability to control the risks specific to the performance of operation and maintenance tasks.

f) One of the main aspects of the operational objective is to ensure and maintain the product

performances through its utilization in its environment of use and up to its disposal. The purpose

of the logistic support elements is to optimize the system’s life cycle cost while maintaining

compliance with all safety-critical and mission-critical requirements.

g) The project or programme team can apply the life cycle cost concept when trading off development

costs versus later utilization phase support and disposal costs.

h) The requirements specified herein shall be responded to by the supplier in his implementation

documents.

4.2 Integration Logistics Support main concepts

4.2.1 Integration Logistics Support concept

Integrating the logistic support into a project or programme is achieved by considering the following

aspects:

a) integrating the customer’s requirements into the design of the system and its support elements;

b) integrating the logistic support activities into the project management organization; and

c) integrating the logistic support elements requirements together.

EXAMPLE The maintenance documentation describes the maintenance actions identified in the

maintenance plan.

4.2.2 Integrated Logistics Support planning

a) The ILS planning assumes that the required external resources (including both maintenance and

other resources) will be provided to the system in its intended operational environment.

b) The ILS planning identifies the required internal resources that will be provided by the logistic

support system to maintain the system in its required operational state, and in its intended

operational environment.

c) The ILS planning addresses both the mission-critical and safety-critical supportability activities of

the ILS programme. ILS planning establishes the activities for achieving the maintenance concepts

and requirements throughout the system utilization phase. The planned logistic support activities

include, but is not limited to:

i) planned levels of repair;

ii) estimated repair times;

iii) testability tools;

iv) support equipment inventory;

v) estimated manpower and skill levels; and

vi) available support facilities.

d) The ILS planning should result in a set of supportability activities that are commensurate with

the system’s unit-value/mission-criticality and logistics support data content/maturity. This type

of planning is sometimes referred to as a capability-based process tailoring. An example of space

systems unit-value/mission-criticality category definitions and guidance for tailoring capability-

based ILS processes are provided in ISO/TS 18667.

4.2.3 Life cycle cost

a) The system life cycle cost of the system is the sum of the acquisition costs, the operation costs, the

maintenance costs, and the disposal costs.

b) The risk of not maintaining system life cycle cost within budget is driven by inherent and extrinsic

risks linked to the system and to the technological, natural, and human environment in which it is

utilized.

c) The ILS process includes the management of these risks as part of the project’s overall risk

management programme. In the case of the system life cycle cost risk analysis, the ILS assists the

trade-off between the cost to meet safety dependability, and quality assurance requirements, and

the achievement of optimized performance for the system. The general synopsis shown in Figure 1

illustrates the complementary nature of this trade-off.

d) ILS is also involved in addressing human factors, through analyses of operation and maintenance

tasks. These analyses are notably based on operability (in particular the man/machine interfaces

and ergonomics), maintenance ability (e.g. qualification, skills, task duration, workload) and

environment (e.g. noise, environmental conditions, organization) criteria.

8 © ISO 2018 – All rights reserved

Figure 1 — Integrated logistic support overview

5 Management requirements for ILS

5.1 Control of logistic activities

5.1.1 Objectives and requirements

The overall project or programme requirements shall clearly state the objectives and requirements in

terms of operational availability, life cycle cost and delivery of the system in its operational environment

of use up to and including its disposal.

[GOAL] Ensure that all the operational environment requirements are identified.

[EXPECTED OUTPUT] Elements of the project requirements document covering operational avail-

ability, project life cycle cost, schedule and product operating environment.

5.1.2 Control of risks

The requirement to control the operational risks related to the system or the system of systems shall be

included in the overall project requirements.

[GOAL] Achieve a balance between the ILS risks and the overall project risks, and to

ensure all ILS risks are assessed and mitigated at the highest level of their

impact in the system or system of systems.

[EXPECTED OUTPUT] An overall approach to risk management.

5.1.3 Concurrent development

The support elements shall be developed concurrently with the system.

[GOAL] Define the support elements early enough, so that:

a) the design and technical solutions selected for the support elements are consistent with the system

definition (design integration concept);

b) the various identified support elements are actually usable in the operational environment of use,

and work together (support elements integration concept); and

c) the customer gets the support elements when required (customer’s requirement integration

concept).

[EXPECTED OUTPUT] Timely availability of the support elements.

5.1.4 Validation

The support elements shall be validated as part of the overall project verification process.

This validation should be enhanced through use of feedback data (lessons learned).

[GOAL] Ensure early enough the ability of the system supportability characteristics

to meet the logistic support requirements.

[EXPECTED OUTPUT] Validated support elements.

5.1.5 Customer participation

The supplier shall make allowances for the customer to participate in the definition and validation of

the support elements.

[GOAL] Ensure that throughout the development phase the system and support elements

design conforms to the customer’s requirements in terms of logistic support.

[EXPECTED OUTPUT] Agreed support elements design.

5.1.6 Integration and synchronization

The logistic support activities, project management, project phasing and planning shall be synchronized.

[GOAL] Synchronized activities

[EXPECTED OUTPUT] Synchronized planning for the overall project.

10 © ISO 2018 – All rights reserved

5.1.7 Work breakdown structure

The logistic activities shall be associated with project work breakdown structure (WBS) and shall be

clearly identifiable as indicated in ISO 14300-1.

[GOAL] To ensure or establish:

a) a consistent and focused identification and management of ILS activities;

b) roles, responsibilities and authority related to the logistic function;

c) conditions enabling roles and responsibilities to be undertaken throughout the project and

especially in early phases A, B and C (see ISO 14300-1); and

d) close customer/supplier communication between the various levels of the project organization.

[EXPECTED OUTPUT] Project WBS containing ILS work packages.

5.1.8 Appropriate phasing

The logistic support activity management in the project shall develop and be implemented at a level

commensurate with the project phase. The project phasing implies consideration of the logistic

activities according to three management responsibility categories:

a) the logistic support management from definition of requirements to acquisition phases (A, B, C, D),

including:

i) ILS management (control of the logistic activities during the system acquisition);

ii) Logistic support analysis (LSA) management (control of the studies aimed at logistic support

specification and validation); and

iii) support elements management (control of the acquisition of specified support elements).

b) the operation and maintenance (O&M) logistic support management - phase E (control of the

support elements use); c) the logistic information management (applicable throughout the project

life cycle).

[GOAL] Consideration of the correct requirements at the appropriate phase of the

project.

[EXPECTED OUTPUT] Balanced definition of ILS activities throughout the project phases.

5.2 Logistic support

5.2.1 Customer summary

a) The customer shall summarize the logistic support requirements in the project requirements

documents.

b) The system or project requirements document should include:

i) a summary of the project objectives to be achieved;

ii) the delivery, operation and maintenance concepts;

iii) the requirement for integrating the logistic support into the project.

---------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.