ISO 14706:2014

(Main)Surface chemical analysis — Determination of surface elemental contamination on silicon wafers by total-reflection X-ray fluorescence (TXRF) spectroscopy

Surface chemical analysis — Determination of surface elemental contamination on silicon wafers by total-reflection X-ray fluorescence (TXRF) spectroscopy

ISO 14706:2014 specifies a TXRF method for the measurement of the atomic surface density of elemental contamination on chemomechanically polished or epitaxial silicon wafer surfaces. The method is applicable to the following: elements of atomic number from 16 (S) to 92 (U); contamination elements with atomic surface densities from 1 × 1010 atoms/cm2 to 1 × 1014 atoms/cm2; contamination elements with atomic surface densities from 5 × 108 atoms/cm2 to 5 × 1012 atoms/cm2 using a VPD (vapour-phase decomposition) specimen preparation method.

Analyse chimique des surfaces — Détermination de la contamination en éléments à la surface des tranches de silicium par spectroscopie de fluorescence X à réflexion totale

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 14706

Second edition

2014-08-01

Surface chemical analysis —

Determination of surface elemental

contamination on silicon wafers by

total-reflection X-ray fluorescence

(TXRF) spectroscopy

Analyse chimique des surfaces — Détermination de la contamination

en éléments à la surface des tranches de silicium par spectroscopie de

fluorescence X à réflexion totale

Reference number

©

ISO 2014

© ISO 2014

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2014 – All rights reserved

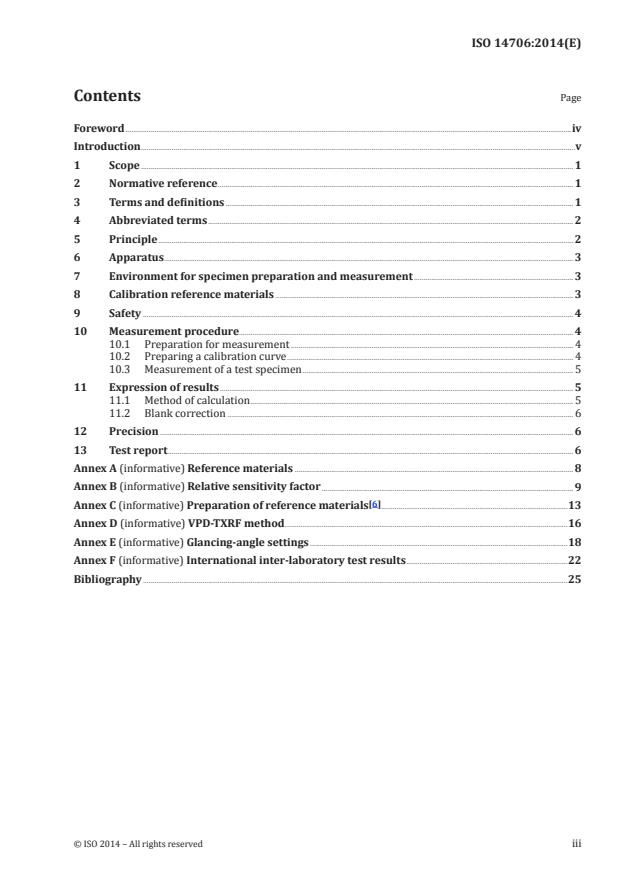

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative reference . 1

3 Terms and definitions . 1

4 Abbreviated terms . 2

5 Principle . 2

6 Apparatus . 3

7 Environment for specimen preparation and measurement . 3

8 Calibration reference materials . 3

9 Safety . 4

10 Measurement procedure . 4

10.1 Preparation for measurement . 4

10.2 Preparing a calibration curve . 4

10.3 Measurement of a test specimen . 5

11 Expression of results . 5

11.1 Method of calculation . 5

11.2 Blank correction . 6

12 Precision . 6

13 Test report . 6

Annex A (informative) Reference materials . 8

Annex B (informative) Relative sensitivity factor . 9

[6]

Annex C (informative) Preparation of reference materials .13

Annex D (informative) VPD-TXRF method .16

Annex E (informative) Glancing-angle settings .18

Annex F (informative) International inter-laboratory test results .22

Bibliography .25

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 201, Surface chemical analysis.

This second edition cancels and replaces the first edition (ISO 14706:2000), which has been technically

revised.

iv © ISO 2014 – All rights reserved

Introduction

This International Standard was prepared for the measurement of surface elemental contamination

on silicon wafers on the basis of three existing standards: ASTM F 1526, SEMI Standard M33, and a

UCS (Ultra-Clean Society) standard published by the Institute of Basic Semiconductor Technology

Development.

TXRF needs reference materials to perform quantitative analyses. Certified reference materials are not

10 2

available at low densities of 10 atoms/cm . Even if they were available, the possibility of contamination

from the environment reduces the shelf life of such reference materials.

Therefore, the TXRF reference materials are to be prepared and analysed for calibration by each relevant

analytical laboratory. Thus, two standards, one for the TXRF measurement procedure and the other for

the preparation of reference materials, are necessary. This International Standard concerns the former

part.

INTERNATIONAL STANDARD ISO 14706:2014(E)

Surface chemical analysis — Determination of surface

elemental contamination on silicon wafers by total-

reflection X-ray fluorescence (TXRF) spectroscopy

1 Scope

This International Standard specifies a TXRF method for the measurement of the atomic surface density

of elemental contamination on chemomechanically polished or epitaxial silicon wafer surfaces.

The method is applicable to the following:

— elements of atomic number from 16 (S) to 92 (U);

10 2 14

— contamination elements with atomic surface densities from 1 × 10 atoms/cm to 1 × 10

atoms/cm ;

8 2 12 2

— contamination elements with atomic surface densities from 5 × 10 atoms/cm to 5 × 10 atoms/cm

using a VPD (vapour-phase decomposition) specimen preparation method (see 3.4).

2 Normative reference

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 14644-1, Cleanrooms and associated controlled environments — Part 1: Classification of air cleanliness

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

total reflection

complete reflection of glancing X-ray radiation into a medium having larger X-ray optical density value

at a boundary between two media

Note 1 to entry: The refractive index of silicon for X-rays is less than 1. X-rays which are incident on the surface

at a small glancing angle are therefore, totally reflected from the surface at an angle equal to the glancing angle.

3.2

glancing angle

angle between the specimen surface plane and the virtual plane containing incident X-rays which

impinge on the sample surface

3.3

critical angle

glancing angle corresponding to the first point of inflection in the plot of the sample matrix X-ray

fluorescence against the glancing angle

3.4

VPD-TXRF method

method in which impurities on the surface are collected by the so-called VPD procedure, i.e. the non-

volatile products formed by acid decomposition of the oxide at the wafer surface are collected by a

droplet of collecting agent, usually ultra-pure hydrofluoric acid, and dried in a manner which gives the

least environmental contamination, the residue from the droplet, subsequently being analysed by TXRF

3.5

spurious peaks

detected peaks that do not originate from impurities on the silicon wafer

Note 1 to entry: Spurious peaks are due to fluorescent X-rays originating from elements in the detector or the X-ray

path. The fluorescent X-rays are excited by direct scattering or reflection of incident X-rays. This phenomenon

leads to an increase in the measurement error. Spurious peaks seriously affect analytical measurements in the

10 2 11 2

contamination range from ca. 10 atoms/cm to ca. 10 atoms/cm .

4 Abbreviated terms

FWHM full width at half maximum

RM reference material

SSD solid-state detector

SDD silicon drift detector

TXRF total-reflection X-ray fluorescence

VPD vapour-phase decomposition

5 Principle

When a specimen is irradiated with X-rays, fluorescence X-rays at characteristic energies of the elements

that constitute the specimen are generated. The intensities of the fluorescence X-rays are proportional

to the amounts of each element in the specimen.

Total reflection of the incident X-rays on the specimen reduces a penetration depth of the incident X-rays

in the specimen. This allows more selective excitation of the fluorescence X-rays from the surface region,

including atoms deposited on the surface of the silicon wafer. Consequently, a spectrum of fluorescence

X-rays with a large ratio of signal to background (S/B) and signal to noise (S/N) can be obtained.

The detection limit depends upon the atomic number, the excitation energy, the photon flux, the

detector resolution and energy-dependent detection efficiency, the energy bandwidth of the excitation

X-rays, the specimen-related shape and statistics of TXRF spectral background, the instrument-related

noise magnitude, the integration time, and the accuracy of calibration of the RM and the blank value.

For constant instrumental parameters, the interference-free detection limits vary over two orders of

magnitude as a function of the atomic number of the analyte element.

NOTE The depth of measurement can vary with the glancing angle, but in the case of film-type contamination

it is usually less than 5 nm. The area of measurement consists of a circle of ca. 10 mm in diameter, though it

varies depending on the relative position of the X-ray detector and the specimen. In the case of particulate-type

contamination on a clean surface, the yield of fluorescence X-rays varies depending on the sizes, d

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.