ASTM E3068-20

(Test Method)Standard Test Method for Contact Measurement of Backface Deformation in Clay Backing During Body Armor Testing

Standard Test Method for Contact Measurement of Backface Deformation in Clay Backing During Body Armor Testing

SIGNIFICANCE AND USE

5.1 U.S. Department of Defense and U.S. Department of Justice standards for assessing the performance of ballistic-resistant torso body armor require the measurement of BFD on backing assemblies made with ROMA Plastilina No. 1®6.

5.2 This test method may be applicable for certification testing or for research and development testing.

SCOPE

1.1 This test method describes test methods for the contact measurement of backface deformation (BFD) in clay backing caused by a test threat that produces a partial penetration in a body armor test item.

1.2 This test method is applicable to testing of planar and nonplanar soft armor and hard armor.

1.3 This test method is not applicable to testing of helmets.

1.4 The purpose of this test method is to achieve consistent measurements between laboratories and reduce differences that could result from using different measurement techniques.

1.5 It is anticipated that this test method will be referenced by certifiers, purchasers, and other users in order to meet their specific needs.

1.6 This test method does not specify BFD performance requirements for body armor. The performance requirements are included in other standards or specifications. The decision rules for determining conformance to specifications and the consideration of uncertainty are also included in other standards or specifications.

1.6.1 In this test method, “other standards and specifications” and “unless specified elsewhere” refer to documents (for example, military standards, purchase specifications) that require the use of this test method. Certifiers, purchasers, and other users are responsible for the “other standards and specifications” and for specifying any requirements that supersede those of this test method.

1.7 Units—The values stated in SI units are to be regarded as standard. Where appropriate, mathematical conversions to non-SI units are provided in parentheses for informational purposes.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E3068 − 20

Standard Test Method for

Contact Measurement of Backface Deformation in Clay

Backing During Body Armor Testing

This standard is issued under the fixed designation E3068; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

1.1 This test method describes test methods for the contact

mine the applicability of regulatory limitations prior to use.

measurement of backface deformation (BFD) in clay backing

1.9 This international standard was developed in accor-

caused by a test threat that produces a partial penetration in a

dance with internationally recognized principles on standard-

body armor test item.

ization established in the Decision on Principles for the

1.2 This test method is applicable to testing of planar and

Development of International Standards, Guides and Recom-

nonplanar soft armor and hard armor.

mendations issued by the World Trade Organization Technical

1.3 This test method is not applicable to testing of helmets. Barriers to Trade (TBT) Committee.

1.4 The purpose of this test method is to achieve consistent

2. Referenced Documents

measurements between laboratories and reduce differences that

2.1 ASTM Standards:

could result from using different measurement techniques.

E3005 Terminology for Body Armor

1.5 It is anticipated that this test method will be referenced

2.2 Other Standards:

by certifiers, purchasers, and other users in order to meet their

MIL-STD-3027 Department of Defense Test Method Stan-

specific needs.

dard for Performance Requirements and Testing of Body

1.6 This test method does not specify BFD performance

Armor

requirements for body armor. The performance requirements

NIJ Standard 0101.06 Ballistic Resistance of Body Armor

are included in other standards or specifications. The decision

NationalResearchCouncil TestingofBodyArmorMaterials

rules for determining conformance to specifications and the

Phase III

consideration of uncertainty are also included in other stan-

3. Terminology

dards or specifications.

1.6.1 In this test method, “other standards and specifica-

3.1 The terms and definitions of Terminology E3005 apply

tions” and “unless specified elsewhere” refer to documents (for

for the following terms: applique, backface deformation,

example, military standards, purchase specifications) that re-

backing fixture, backing material, body armor, bridge gauge,

quire the use of this test method. Certifiers, purchasers, and

check standard, clay block, complete penetration, depth gauge,

other users are responsible for the “other standards and

floating gauge, hard armor, nonplanar, partial penetration, soft

specifications” and for specifying any requirements that super-

armor, striking device, test item, and test threat.

sede those of this test method.

3.1.1 Examples of backface deformation (BFD) are pro-

vided in Fig. 1.

1.7 Units—The values stated in SI units are to be regarded

3.1.2 See Fig. 2 for a photograph of a bridge gauge.

as standard. Where appropriate, mathematical conversions to

3.1.3 See Fig. 3 for a graphical representation of a clay

non-SI units are provided in parentheses for informational

block.

purposes.

1.8 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

1 3

This test method is under the jurisdiction of ASTM Committee E54 on Available from IHS, 15 Inverness Way East, Englewood, CO 80112, http://

Homeland Security Applications and is the direct responsibility of Subcommittee www.global.ihs.com.

E54.04 on Personal Protective Equipment (PPE). AvailablefromNationalInstituteofJustice(NIJ),8107thSt.,NW,Washington,

Current edition approved April 1, 2020. Published April 2020. Originally DC 20531, http://nij.gov.

ɛ1 5

approved in 2017. Last previous edition approved in 2017 as E3068 – 17 . DOI: Available from The NationalAcademies Press, 500 Fifth St., NW, Washington,

10.1520/E3068-20. DC 20001, https://www.nap.edu.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E3068 − 20

FIG. 1 Examples of Backface Deformation (Side View)

FIG. 2 Photograph of Bridge Gauge

4. Summary of Test Method resistant torso body armor require the measurement of BFD on

®6

backing assemblies made with ROMA Plastilina No. 1 .

4.1 Ballistic testing of body armor typically requires shoot-

ing body armor test items mounted on clay blocks. 5.2 This test method may be applicable for certification

testing or for research and development testing.

4.2 One of the ballistic test methods for body armor

specifies that the BFD be measured when shooting of the test

6. Equipment and Instrumentation

item results in a partial penetration. When the shot results in a

6.1 The measuring instrument shall have a resolution of

complete penetration, BFD is not measured.

0.01 mm (0.0004 in.) or better with an accuracy of 60.1 mm

4.3 This test method describes the measurement

(0.004 in.) or better.

instrumentation,theBFDmeasurand,andtheprocedureforthe

6.2 Three types of contact measuring instruments may be

use of contact measurement instruments.

used:

5. Significance and Use

6 ®

5.1 U.S. Department of Defense and U.S. Department of

U.S. Government standards require ROMA Plastilina No. 1 , from Sculpture

Justice standards for assessing the performance of ballistic- House, Inc., as the backing material for ballistic resistance testing.

E3068 − 20

FIG. 3 Side View of Clay Block (After Impact)

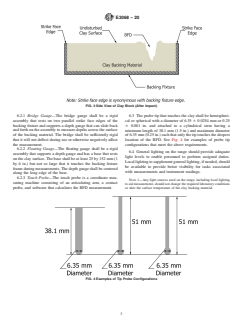

6.2.1 Bridge Gauge—The bridge gauge shall be a rigid 6.3 The probe tip that touches the clay shall be hemispheri-

assembly that rests on two parallel strike face edges of the

cal or spherical with a diameter of 6.35 6 0.0254 mm or 0.25

backing fixture and supports a depth gauge that can slide back 6 0.001 in. and attached to a cylindrical stem having a

and forth on the assembly to measure depths across the surface

minimum length of 38.1 mm (1.5 in.) and maximum diameter

of the backing material. The bridge shall be sufficiently rigid

of 6.35 mm (0.25 in.) such that only the tip touches the deepest

that it will not deflect during use or otherwise negatively affect

location of the BFD. See Fig. 4 for examples of probe tip

the measurement.

configurations that meet the above requirements.

6.2.2 Floating Gauge—The floating gauge shall be a rigid

6.4 General lighting on the range should provide adequate

assembly that supports a depth gauge and has a base that rests

light levels to enable personnel to perform assigned duties.

on the clay surface. The base shall be at least 25 by 152 mm (1

Locallightingtosupplementgenerallighting,ifneeded,should

by 6 in.) but not so large that it touches the backing fixture

be available to provide better visibility for tasks associated

frame during measurements.The depth gauge shall be centered

with measurements and in

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: E3068 − 17 E3068 − 20

Standard Test Method for

Contact Measurement of Backface Deformation in Clay

Backing During Body Armor Testing

This standard is issued under the fixed designation E3068; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Added research report footnote to Section 12 editorially in April 2017.

1. Scope

1.1 This test method describes test methods for the contact measurement of backface deformation (BFD) in clay backing caused

by a test threat that produces a partial penetration in a body armor test item.

1.2 This test method is applicable to testing of planar and nonplanar soft armor and hard armor.

1.3 This test method is not applicable to testing of helmets.

1.4 The purpose of this test method is to achieve consistent measurements between laboratories and reduce differences that

could result from using different measurement techniques.

1.5 It is anticipated that this test method will be referenced by certifiers, purchasers, and other users in order to meet their

specific needs.

1.6 This test method does not specify BFD performance requirements for body armor. The performance requirements are

included in other standards or specifications. The decision rules for determining conformance to specifications and the

consideration of uncertainty are also included in other standards or specifications.

1.6.1 In this test method, “other standards and specifications” and “unless specified elsewhere” refer to documents (for example,

military standards, purchase specifications) that require the use of this test method. Certifiers, purchasers, and other users are

responsible for the “other standards and specifications” and for specifying any requirements that supersede those of this test

method.

1.7 Units—The values stated in SI units are to be regarded as standard. Where appropriate, mathematical conversions to non-SI

units are provided in parentheses for informational purposes.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

E3004 Specification for Preparation and Verification of Clay Blocks Used in Ballistic-Resistance Testing of Torso Body Armor

E3005 Terminology for Body Armor

This test method is under the jurisdiction of ASTM Committee E54 on Homeland Security Applications and is the direct responsibility of Subcommittee E54.04 on

Personal Protective Equipment (PPE).

Current edition approved Feb. 1, 2017April 1, 2020. Published March 2017April 2020. Originally approved in 2017. Last previous edition approved in 2017 as

ɛ1

E3068 – 17 . DOI: 10.1520/E3068-17E01.10.1520/E3068-20.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E3068 − 20

2.2 Other Standards:

MIL-STD-3027 Department of Defense Test Method Standard for Performance Requirements and Testing of Body Armor

NIJ Standard 0101.06 Ballistic Resistance of Body Armor

National Research Council Testing of Body Armor Materials Phase III

3. Terminology

3.1 The terms and definitions of Terminology E3005 apply for the following terms: applique, backface deformation, backing

fixture, backing material, body armor, complete penetration, bridge gauge, check standard, clay block, complete penetration, depth

gauge, floating gauge, hard armor, nonplanar, partial penetration, soft armor, striking device, test item, and test threat.

3.1.1 Examples of backface deformation (BFD) are provided in Fig. 1.

3.1.2 See Fig. 2 for a photograph of a bridge gauge.

3.1.3 See Fig. 3 for a graphical representation of a clay block.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 applique, n—backing material intended to fill the space behind a nonplanar test item during testing or conditioning

procedures.

3.2.2 backface deformation (BFD), n—the indentation in the backing material caused by a projectile impact on the test item

during testing. E3005

3.2.2.1 Discussion—

FIG. 1 Examples of Backface Deformation (Side View)

Available from IHS, 15 Inverness Way East, Englewood, CO 80112, http://www.global.ihs.com.

Available from National Institute of Justice (NIJ), 810 7th St., NW, Washington, DC 20531, http://nij.gov.

Available from The National Academies Press, 500 Fifth St., NW, Washington, DC 20001, https://www.nap.edu.

E3068 − 20

FIG. 2 Photograph of Bridge Gauge

FIG. 3 Side View of Clay Block (After Impact)

See Fig. 1.

3.2.3 bridge gauge, n—an assembly used for measuring that consists of a depth gauge and supports that rest on opposite sides

of the backing fixture. E3004

3.2.3.1 Discussion—

See Fig. 2 for a photograph of a bridge gauge.

3.2.4 check standard, n—stable, durable artifact that may be used for training, comparing among measuring instruments, and

checking instruments prior to and after calibration, maintenance, or normal use to detect changes in the instruments.

®6

3.2.5 clay block, n—a type of backing assembly in which the backing material is ROMA Plastilina No. 1 modeling clay.

E3004

3.2.5.1 Discussion—

See Fig. 3 for a graphical representation of a clay block.

3.2.6 depth gauge, n—instrument (for example, caliper) used to measure the indentations in the backing material.

3.2.7 floating gauge, n—a depth gauge that rests on the surface of the backing material.

3.2.8 striking device, n—a device used on a clay block to establish an appropriate, flat surface on the clay backing material with

respect to the backing fixture edges. E3004

E3068 − 20

4. Summary of Test Method

4.1 Ballistic testing of body armor typically requires shooting body armor test items mounted on clay blocks.

4.2 One of the ballistic test methods for body armor specifies that the BFD be measured when shooting of the test item results

in a partial penetration. When the shot results in a complete penetration, BFD is not measured.

4.3 This test method describes the measurement instrumentation, the BFD measurand, and the procedure for the use of contact

measurement instruments.

5. Significance and Use

5.1 U.S. Department of Defense and U.S. Department of Justice standards for assessing the performance of ballistic-resistant

® 6

torso body armor require the measurement of BFD on backing assemblies made with ROMA Plastilina No. 1 . .

5.2 This test method may be applicable for certification testing or for research and development testing.

6. Equipment and Instrumentation

6.1 The measuring instrument shall have a resolution of 0.01 mm (0.0004 in.) or better with an accuracy of 60.1 mm (0.004

in.) or better.

6.2 Three types of contact measuring instruments may be used:

6.2.1 Bridge Gauge—The bridge gauge shall be a rigid assembly that rests on two parallel strike face edges of the backing

fixture and supports a depth gauge that can slide back and forth on the assembly to measure depths across the surface of the backing

material. The bridge shall be sufficiently rigid that it will not deflect during use or otherwise negatively affect the measurement.

6.2.2 Floating Gauge—The floating gauge shall be a rigid assembly that supports a depth gauge and has a base that rests on

the clay surface. The base shall be at least 25 by 152 mm (1 by 6 in.) but not so large that it touches the backing fixture frame

during measurements. The depth gauge shall be centered

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.